THE UNIVERSITY OF NOTTINGHAM Recruitment Role

advertisement

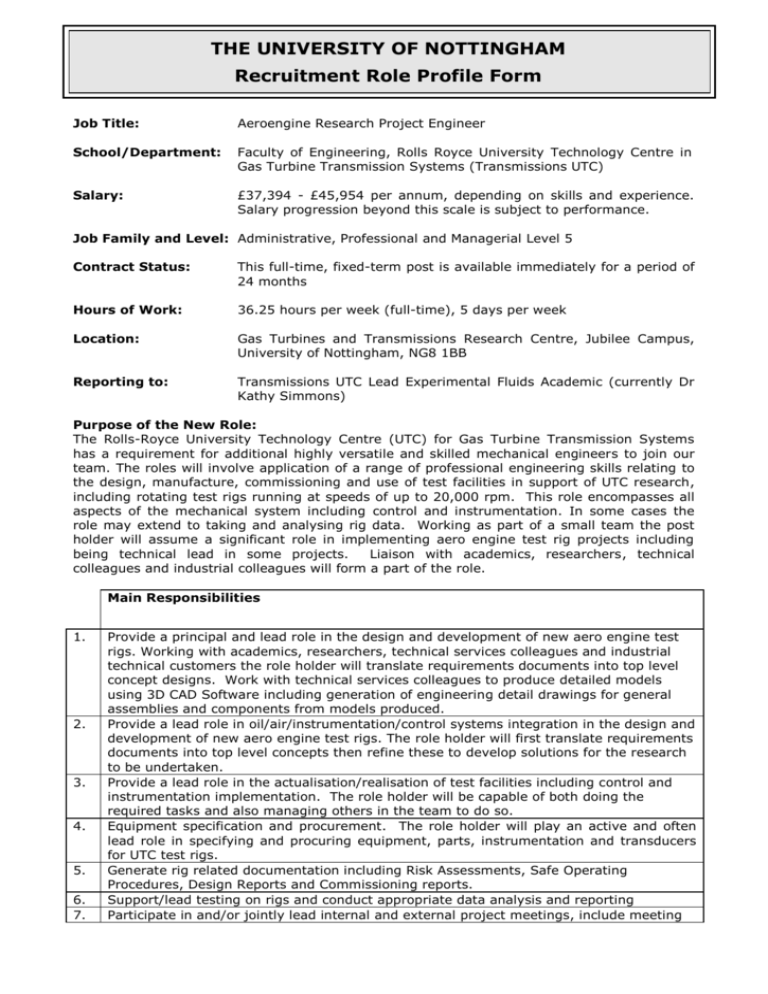

THE UNIVERSITY OF NOTTINGHAM Recruitment Role Profile Form Job Title: Aeroengine Research Project Engineer School/Department: Faculty of Engineering, Rolls Royce University Technology Centre in Gas Turbine Transmission Systems (Transmissions UTC) Salary: £37,394 - £45,954 per annum, depending on skills and experience. Salary progression beyond this scale is subject to performance. Job Family and Level: Administrative, Professional and Managerial Level 5 Contract Status: This full-time, fixed-term post is available immediately for a period of 24 months Hours of Work: 36.25 hours per week (full-time), 5 days per week Location: Gas Turbines and Transmissions Research Centre, Jubilee Campus, University of Nottingham, NG8 1BB Reporting to: Transmissions UTC Lead Experimental Fluids Academic (currently Dr Kathy Simmons) Purpose of the New Role: The Rolls-Royce University Technology Centre (UTC) for Gas Turbine Transmission Systems has a requirement for additional highly versatile and skilled mechanical engineers to join our team. The roles will involve application of a range of professional engineering skills relating to the design, manufacture, commissioning and use of test facilities in support of UTC research, including rotating test rigs running at speeds of up to 20,000 rpm. This role encompasses all aspects of the mechanical system including control and instrumentation. In some cases the role may extend to taking and analysing rig data. Working as part of a small team the post holder will assume a significant role in implementing aero engine test rig projects including being technical lead in some projects. Liaison with academics, researchers, technical colleagues and industrial colleagues will form a part of the role. Main Responsibilities 1. 2. 3. 4. 5. 6. 7. Provide a principal and lead role in the design and development of new aero engine test rigs. Working with academics, researchers, technical services colleagues and industrial technical customers the role holder will translate requirements documents into top level concept designs. Work with technical services colleagues to produce detailed models using 3D CAD Software including generation of engineering detail drawings for general assemblies and components from models produced. Provide a lead role in oil/air/instrumentation/control systems integration in the design and development of new aero engine test rigs. The role holder will first translate requirements documents into top level concepts then refine these to develop solutions for the research to be undertaken. Provide a lead role in the actualisation/realisation of test facilities including control and instrumentation implementation. The role holder will be capable of both doing the required tasks and also managing others in the team to do so. Equipment specification and procurement. The role holder will play an active and often lead role in specifying and procuring equipment, parts, instrumentation and transducers for UTC test rigs. Generate rig related documentation including Risk Assessments, Safe Operating Procedures, Design Reports and Commissioning reports. Support/lead testing on rigs and conduct appropriate data analysis and reporting Participate in and/or jointly lead internal and external project meetings, include meeting 8. reporting where appropriate. Any other duties associated with the role. Knowledge, Skills, Qualifications & Experience Qualifications/ Education Essential Mechanical/ Manufacturing/ Aerospace/ Automotive/ Chemical Engineering qualification to BEng level or equivalent, or better Skills/Training Experience Proven overall concept and design skills applied to complex test rigs or similar Facility with use of at least one parametric 3D CAD package Basic understanding of fluid mechanics Basic understanding of instrumentation Hands on subsystem build/ debugging skills. Clear communication skills at all levels. Workshop familiarity with knowledge of use of tools/ equipment to the extent needed to manage acquisition of complex precision engineered assemblies. Broad familiarity with Instrumentation Broad familiarity with the development of data acquisition systems Broad familiarity with all mechanical engineering concepts relevant to the operation of rotating machines or test rigs or other industrial equipment. Experience of applying the knowledge gained through academic qualifications including situations where the optimal engineering solution may not be immediately apparent and there is a mass of information or diverse, partial and conflicting data, with a range of Page 2 of 3 Desirable MEng in Mechanical Engineering at 2:1 or equivalent, or better PhD or equivalent in a relevant field Professional qualification in engineering Rotating test rig or turbomachinery design / development experience Experienced user of ‘Creo’ Software. (ie Pro Engineer) Vibration sensing for rotor balancing and knowledge of special requirements for designs involving high speeds. Instrument calibration knowledge. Application of electric motors, drives and mechanical transmissions LabVIEW training/capability. A high level of LabVIEW expertise is preferred. Any familiarity with laser techniques (LDA, PIV etc), high speed rotatives, shaft stability, structural stability, bearing selection, vibration, strain gauging, high speed cameras is an advantage. 2 years of C&I track record Oils or fluid handling Instrumentation design experience selecting and installing appropriate instrumentation for equipment / test rigs. Experience of developing data acquisition systems, including calibration for instrumented equipment. Experience on a wide range of design projects. Direct experience with large high-speed rotating machinery/ rigs. Knowledge of aerospace industry engineering requirements. Experience of working within an organization such as a University or company R&D / Design environment. Statutory/Legal potential options available. There must be evidence of independent thought and ability to deal with ambiguity. Experience with industrial communications buses (RS 232, Modbus, EtherCAT etc) Experience with risk analysis specific to rotating test rigs. Eg electrical hazards, safe shutdown, interlocks, fire. The interpretation and implementation of work related regulations and procedures and an understanding of non-compliance on other staff and the University (e.g. Health and Safety) Decision Making i) taken independently by the role holder Prioritisation of work load. All general day to day decisions. Technical decisions relating research programs and support. Purchasing of materials up to budgetary limits. Ensuring research tasks and time scales are maintained. Maintaining rigs and equipment. Setting up rigs and equipment as requested. Arranging for manufacture of items as needed. Obtaining quotes for parts, rigs and services. Training needs General University Administration Safety awareness ii) taken in collaboration with others Liaison with all categories of staff in relevant areas. Directing support staff as required. Participating in formal/informal design reviews against programme requirements. Providing technical advice and support academic staff and researchers as requested. iii) referred to the appropriate line manager (please name) by the role holder Purchasing high cost items Key facility design decisions Communications with external funding bodies Additional Information The role holder will be responsible for achieving and maintaining high standards with regard to technical support of the research programs. Although part of a specific research team, the role holder will be required to work to a large extent on their own initiative and be expected to set their own day to day priorities. The role demands that undergraduates, postgraduates and academics needs are met thereby ensuring the efficient carrying out of research of the highest quality and to agreed timescales. Page 3 of 3