Copper to Copper

advertisement

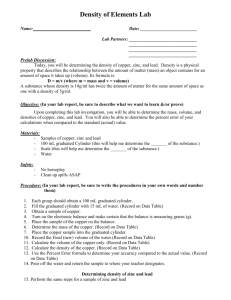

Copper to Copper Hayriye Polik Asna Ashfaq and Isabella Stubbs AP Chemistry 3rd Period Dr. Kerr 08/28/2014 Purpose: The purpose of this lab is to see how copper can be reacted with multiple substances and then reversed back to copper in the end. Materials: 5.5 mL Concentrated Nitric Acid Distilled Water 30 mL of 3 M NaOH 0.5 g Copper Turnings 15 mL 6 M H2SO4 Zinc Powder 250 mL beaker Heat Plate Stirring Rod Filter Paper Erlenmeyer Flask Acetone Procedure: 1. Reaction 1 a. Measure 0.5 g copper turnings into 250 mL beaker. Add 5.5 mL concentrated nitric acid in the fume hood. b. Add 75 - 100 mL distilled water after reaction is complete. 2. Reaction 2 a. Add 30 mL of 3 M NaOH to the solution above. 3. Reaction 3 a. Carefully heat the beaker containing Cu(OH)2 solid (frothing is normal) until contents are totally black. Don't overheat. b. Allow the black precipitate to settle. Decant. wash the precipitate with warm water and decant to isolate black precipitate. 4. Reaction 4 a. Slowly add 15 mL of 6 M H2SO4 to the black solid. Stir. 5. Reaction 5 a. Add 2 g of zinc powder to the solution. All the zinc should be gone from the reaction container at the end of the reaction. If not, add additional H2SO4. If all the Cu2+ ions are not gone, add more zinc. b. When the reaction is complete, filter. Wash the solid copper with water then acetone. Let the solid copper dry. Weigh the copper and filter paper and calculate percent recovery. If a white precipitate forms, add some warm water and stir. Results: Measurements and Data: Mass of Copper Turnings Mass of Filter Paper and Dried Copper Mass of Filter Paper Mass of Dried Copper Percent Recovery 0.5 g 1.32 g 0.89 g 0.43 g 90 % Reactions and Observations: Reaction Type of Reaction OxidationReduction Formula Qualitative Observations Cu(s) + 4HNO3 -> Cu(NO3)2 (aq) + 2NO2 (g) + 2H2O (l) 2 Precipitation Cu(NO3)2 (aq) + 2NaOH (aq) -> Cu(OH)2 (aq) + 2NaNO3 (aq) 3 Decomposition Cu(OH)2 (aq) -> CuO (aq) + H(OH) (l) 4 Precipitation CuO (aq) + H2SO4 (aq) -> CuSO4 (aq) + H(OH) (l) 5 Single Replacement CuSO4 (aq) + Zn (s) -> ZnSO4 (aq) + Cu (s) Copper turnings and nitric acid turned green and released brown/yellow gas. Solution slowly turned blue. Upon adding water, substance turned aqua blue. Solution clouded up and turned cobalt blue. Jelly-like precipitate formed. While heating beaker with Cu(OH)2, jelly-like substance turned liquid. It became darker over time, first turning dark green then black. Black particles started forming; this was the black precipitate. Upon adding 6 M H2SO4, precipitate turned light brown and homogeneous; became clearer and green. With more stirring the solution turned light blue. As stirring continued, the zinc powder turned reddish orange (the copper). It clumped and became solid. This was the copper. 1 Analysis: 1.32 g (Mass of filter paper and Cu) - 0.89 g (Mass of filter paper) = 0.43 g (mass of Cu) 0.43 g Cu (ending result) / 0.5 g Cu (initial value) = 0.86(100) = 86% (need only one significant figure because of 0.5 g, so the percent rounds up to 90%) = 90% recovery of Copper Conclusion: In all, a range of chemical reactions were used to manipulate copper to reverse back into its elemental form. Even though the coils weren't produced in the end, the pure copper was produced, which was the main idea of the lab. There was a source of error because only 90% of the copper was recovered. One source could be from human mistake in inaccurate measurements of substances. A clear source of error occurred with decanting, because the black particles were very challenging to keep from spilling into the sink. Another source of error could be while stirring the Zinc powder with the solution: there wasn't enough time to make sure that all of the zinc ions reacted with the Copper (II) Sulfate, which was the light blue solution. Being short on time affected how the procedures were performed hurriedly and quickly. In conclusion, most of the Copper was recovered through four different types of chemical equations.