List of Manufacturing Process final examination Identify some of the

advertisement

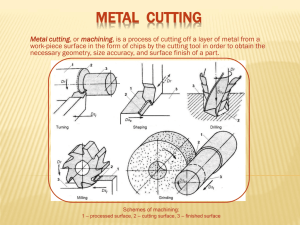

List of Manufacturing Process final examination 1. Identify some of the important advantages of shape casting processes. 2. What is the meaning of manufacturing process and Mention and explain kind of manufacturing process (at least 4) 3. What are some of the limitations and disadvantages of casting? 4. What is the difference between an open mold and a closed mold? 5. What is meant by the term superheat? 6. What do you know about atributes and variables in measurement? 7. What do you know about allowance and tolerance ? mention kind of it (min 2) 8. Explain what does it meant : (a) 0.05, (b) ∅50+0.01 −0.05 , (c) 9. What do you know about forging and rolling ? give example products each of them (min 2) 10. Define criterion of sheet metal working (min 4) 11. What is the difference of blanking and piercing in sheet metal working ? 12. What do you know about machining process, and give examples (min 2) ? 13. Mention advantages and disadvantages of machining process (min 3) 14. Mention kind of material removal process and give examples (min 2). 15. What is the difference between threading and tapping ? 16. What do you know about welding and explain kind of welding (min 2) ? 17. What do you know about abrasive machine process and give 2 examples 18. What do you know about milling and turning ? explain it briefly 19. What is main energy tend to non traditional machining and describe it (min 3). 20. What are the advantage of non traditional machining process ? (min 3) 21. What do you know about Electric Discharge machine and the usage, explain it briefly. 22. What do you now about TIG welding ? 23. What are some of the cutting tool criteria used in production machining operations? 24. Identify the parameters of a machining operation that are included within the scope of cutting conditions (min 3), explain briefly. 25. What is the difference between booring and drilling ? 26. Describe kind of milling machine 27. A workbar with 5.0 in diameter and 48 in length is chucked in an engine lathe and supported at the opposite end using a live center. A 40.0 in portion of the length is to be turned to a diameter of 4.75 in one pass at a speed = 400 ft/min and a feed = 0.012 in/rev. Determine: (a) the required depth of cut, (b) cutting time, and (c) metal removal rate. 28. The end of a large tubular workpart is to be faced on a NC vertical boring mill. The part has an outside diameter = 45.0 in and inside diameter = 25 in. If the facing operation is performed at a rotational speed = 30 rev/min, feed = 0.020 in/rev, and depth = 0.150 in, determine: (a) the cutting time to complete the facing operation, (b) the cutting speeds and metal removal rates at the beginning and end of the cut. 29. Arrange list of script to make workpart using milling machine, according to this criterion: a. Material stock (LxWxH) : 100 x 80 x 60 b. Tools availables (unit: mm) : - T01 : Ø 50 - T02 : Ø 40 - T03 : Ø 10 - T04 :Ø5 c. Zero point and reference point define by your self (must state) d. Unit, mode of movement, coordinate system, spindle speed, feedrate, spindle orientation, coolant function (if needed) please define your self. e. Kind of material, machine specification, allowance and tollerance are ignored. f. Calculate CSS for Ø 50 (spindle speed according to your script that you already define before)