Supplementary Information Production of Δ9

advertisement

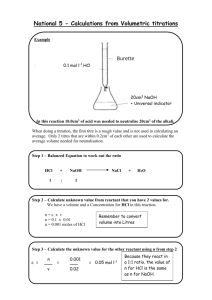

Supplementary Information Production of Δ9-tetrahydrocannabinolic acid from cannabigerolic acid by whole cells of Pichia (Komagataella) pastoris expressing Δ9-tetrahydrocannabinolic acid synthase from Cannabis sativa L. Bastian Zirpel 1, Felix Stehle1,*, Oliver Kayser1 1 Laboratory of Technical Biochemistry, Department of Biochemical & Chemical Engineering, TU Dortmund University, Dortmund, Germany *Correspondence to: Felix Stehle Laboratory of Technical Biochemistry, Department of Biochemical & Chemical Engineering, TU Dortmund University, Emil-Figge-Str. 66 , 44227 Dortmund, Germany felix.stehle@bci.tu-dortmund.de Supplementary Table 1: List of microorganisms used for expression of THCAS Organism Strain Company Genotype E. coli SHuffle NEB, Frankfurt, fhuA2 lacZ::T7 gene1 [lon] ompT ahpC gal T7 Express Germany λatt::pNEB3-r1-cDsbC (SpecR, lacIq) ΔtrxB sulA11 R(mcr-73::miniTn10--TetS)2 [dcm] R(zgb-210::Tn10--TetS) endA1 Δgor ∆(mcrC-mrr)114::IS10 E. coli SHuffle NEB, Frankfurt, lacZ::T7 gene1 [lon] ompT ahpC gal T7 Express lysY Germany λatt::pNEB3-r1-cDsbC (SpecR, lacIq) ΔtrxB sulA11 R(mcr-73::miniTn10--TetS)2 [dcm] R(zgb-210::Tn10--TetS) endA1 Δgor ∆(mcrC-mrr)114::IS10 S. cerevisiae S. cerevisiae CEN.PK2-1C Euroscarf, Frankfurt, MATa; gal1::loxP; ura3-52; trp1-289; leu2- Δgal1 Germany 3,112; his3Δ 1; MAL2-8C; SUC2 CEN.PK2-1C this work MATa; gal1::loxP; pep4::loxP; ura3-52; Δgal1Δpep4 trp1-289; leu2-3,112; his3Δ 1; MAL2-8C; SUC2 P. pastoris PichiaPink1 Invitrogen, Darmstadt, ade2 Germany P. pastoris PichiaPink2 Invitrogen, Darmstadt, ade2; pep4 Germany P. pastoris PichiaPink3 Invitrogen, Darmstadt, Germany ade2; prb1 Supplementary Table 2: List of plasmids Plasmid Features pET28a(+)_THCAS pET28(a+) (Merck, Darmstadt, Germany) with cDNA of THCAS; cloned into NdeI and HindIII restriction sites pET32a(+)_THCAS pET32a(+) (Merck, Darmstadt, Germany) with cDNA of THCAS; cloned into NcoI and HindIII restriction sites pDionysos_THCAS pDionysos with cDNA of THCAS codon usage optimized for S. cerevisiae; Nterminal 5’UTR (AAAAAA) followed by sequence coding for 24 aa signal peptide of proteinase A (Uniprot P07267); C-terminal sequence coding for 3 additional histidines; cloned into HindIII and XbaI restriction sites pPink_HC_THCAS pPink-HC (Invitrogen, Darmstadt, Germany) with cDNA of THCAS codon usage optimized for P. pastoris; N-terminal 5’UTR (AAAAAA) followed by sequence coding for 24 aa signal peptide of proteinase A (Uniprot F2QUG8); C-terminal sequence coding for 3 additional histidines; cloned into EcoRI and KpnI restriction sites pPink_LC_THCAS pPink-LC (Invitrogen, Darmstadt, Germany) with cDNA of THCAS codon usage optimized for P. pastoris; N-terminal 5’UTR (AAAAAA) followed by sequence coding for 24 aa signal peptide of proteinase A (Uniprot F2QUG8); C-terminal sequence coding for 3 additional histidines; cloned into EcoRI and KpnI restriction sites Figures Supplementary Figure 1: Screening of P. pastoris clones - volumetric THCAS activity; cultures were inoculated at 0.105 gCDW l-1. Cultures were grown at 200 rpm and 20 °C. Methanol was added every 24 h at 0.5 % (v/v). Values are calculated from biological duplicates. Supplementary Figure 2: Screening of P. pastoris clones - specific THCAS activity; cultures were inoculated at 0.105 gCDW l-1. Cultures were grown at 200 rpm and 20 °C. Methanol was added every 24 h at 0.5 % (v/v). Values are calculated from biological duplicates. Supplementary Figure 3: Expression of THCAS using PP2_HC; Cultures were grown in 3-baffled shake-flasks at 200 rpm and 10 °C. Methanol was added every 24 h at 0.5 % (v/v). Data points represent the means of three biological replicates with two technical replicates and error bars represent the standard deviation. Supplementary Figure 4: Expression of THCAS using PP2_HC; Cultures were grown in 3-baffled shake-flasks at 200 rpm and 20 °C. Methanol was added every 24 h at 0.5 % (v/v). Data points represent the means of three biological replicates with two technical replicates and error bars represent the standard deviation. Supplementary Figure 5: Expression of THCAS using PP2_HC; Cultures were grown in 3-baffled shake-flasks at 200 rpm and 25 °C. Methanol was added every 24 h at 0.5 % (v/v). Data points represent the means of three biological replicates with two technical replicates and error bars represent the standard deviation. Additional Information Media composition 2 x YPAD medium (pH 5.5): 20 g yeast extract l-1, 40 g peptone l-1, 4.41 g citric acid monohydrate l-1, 25.63 g tripotassium citrate monohydrate l-1, 10 mg riboflavin l-1, 80 mg adenine hemisulfate l-1, 40 g fructose l-1, 5 g galactose l-1. BMGY medium (pH 6): 10 g yeast extract l-1, 20 g peptone l-1, 100 mM phosphate buffer pH 6.0, 13.8 g yeast nitrogen base l-1, 0.4 mg biotin l-1, 10 g glycerol l-1. Modified BMMY (mBMMY) medium (pH 5.5) (adapted from Taura et al. 2007): 10 g yeast extract l-1, 20 g peptone l-1, 5 g casamino acids l-1, 100 mM sodium citrate buffer pH 5.5, 13.8 g yeast nitrogen base l-1, 0.4 mg biotin l-1, 10 mg riboflavin l-1, 1 % (v/v) methanol. Generation of E. coli strains for intracellular THCAS expression pGEM-T-easy(modified) carrying the plant cDNA of THCAS – THCAS sequence was amplified using the primers (5’-GATCCATATGAATCCTCGAGAAAACTTCCTTAAATGCTTCT-3’ and 5’-GCATAAGCTT CTATTAATGATGATGCGGTGGAAGAGG-3’) and cut with NdeI and HindIII for insertion into pET28a(+) or with primers (5’-GACTCCATGGCTAATCCTCGAGAAAACTTCCTTAAATGCTTCT-3’ and 5’-GCATA AGCTTCTATTAATGATGATGCGGTGGAAGAGG-3’) and cut with NcoI and HindIII for insertion into pET32a(+). The vectors generated contained the cDNA of THCAS without signal peptide and were transformed into E. coli SHuffle T7 Express and E. coli SHuffle T7 Express lysY. Generation of S. cerevisiae strains for intracellular THCAS expression A cDNA coding for the THCAS without the first 84 bp (native signal peptide) and optimized for the codon-usage in S. cerevisiae was obtained from GeneArt (Regensburg, Germany). The cDNA was amplified by PCR with gene-specific primers (5’-GGGAATTCAAGCTTAAAAAAATGTCCAGCTTGAAAGCATTAT TGCCATTGGCCTTGTTGTTGGTCAGCGCCAACCAAGTTGCTGCAAACCCTAGAGAAAACTTTTTGA ATG-3’ and 5’-GACTTCTAGATCATTAATGATGATGATGGTGATGTGGAGGCAATG GAGGGATGG-3’) to introduce a 5’UTR consensus sequence from S. cerevisiae in the 5’ untranslated region followed by a sequence coding for a 24 amino acid signal peptide from S. cerevisiae vacuolar proteinase A (UniProt accession number P07267) and three histidine residues to complement a His6-tag at the C-terminus of the protein. The PCR product was purified from gel and cloned into pDionysos using HindIII and XbaI restriction sites. The empty vector was transformed as negative control. Transformants were selected on minimal medium agar without leucine. Generation of P. pastoris strains for intracellular THCAS expression A cDNA coding for the THCAS without the first 84 bp (native signal peptide) and optimized for the codon-usage in P. pastoris was ordered from GeneArt. The cDNA was amplified by PCR with gene-specific primers (5’-GCATACGAATTCAAAAAAATGTCTATATTTGACGGTACTACGATGTCAATTGCCATTGGTTT GCTCTCTACTCTAGGTATTGGTGCTGAAGCCAACCCAAGAGAAAACTTCTTGAAGTG-3’ and 5’-CGCTAGGGTACCTTATTAATGATGATGATGATGATGTGGTGGCAATGG-3’) to introduce a 5’-UTR consensus sequence from S. cerevisiae in front of the start codon followed by a sequence coding for a 24 amino acid signal peptide from P. pastoris vacuolar proteinase A (UniProt accession number F2QUG8) and 3 histidine residues to complement a His6-tag at the C-terminus of the protein. The PCR product was purified from gel and cloned into the low copy number (pPink -LC) and high copy number (pPink -HC) vectors downstream of the AOX1 promoter using EcoRI and KpnI restriction sites. The three PichiaPink strains 1, 2 and 3 were transformed with linearized (cut with SpeI; chromosomal introduction into TRP2 gene) pPink-LC_THCAS or pPink – HC_THCA plasmids. The empty vectors were transformed as negative controls. Transformants were selected on Pichia adenine dropout (PAD) agar. Cell lysis of E. coli cells Cell cultures were centrifuged for 20 min at 4 °C and 5,000 g. Cell pellet was resuspended in 6 ml 100 mM sodium citrate buffer pH 5.5. The cell suspension was supplemented with 10 mg lysozyme ml -1 and incubated for 20 min at room temperature. Afterwards 10 mg DNaseI ml -1 was added and the cell suspension incubated at room temperature for 10 min. Cells were lysed by sonication on ice at an amplitude of 10 % (10 x 6 s pulse on, 30 s pulse off). The lysate was centrifuged for 30 min at 5.000 g and 4 °C and the supernatant used for activity assays. Cell lysis of S. cerevisiae and P. pastoris cells Cells were harvested by centrifugation of 450 µl cell suspension at 13,000 g at 4 °C for 5 min. Supernatants were discarded and cells resuspended in 450 µl 100 mM sodium citrate buffer pH 5.5. After addition of 75 U lyticase ml-1 (Sigma Aldrich), cells were incubated at 37 °C and 1,100 rpm for 10 min in a shaking incubator. Cell suspension was transferred to 0.5 ml tubes and filled with 0.25 mm – 0.5 mm glass beads. Cells were lysed by vortexing at maximum speed at 4 °C for 10 min. Cell lysate was centrifuged and supernatant used for activity assays. Screening of P. pastoris transformants for high THCAS activity From PAD agar plates five white colonies of each strain were picked for inoculation of 2 ml BMGY in glass tubes. Cells were incubated at 30 °C in a rotary shaker. After 24 h cultures were centrifuged and pellet washed with 0.9 % NaCl, centrifuged and pellet resuspended in 2 ml of BMMY. 50 µl of the suspensions was used to inoculate 2 ml of BMMY in glass tubes, respectively. Cells were cultivated at 30 °C in the rotary shaker for 72 h. The clone with the highest activity was selected of each strain and used for inoculation of 50 ml BMGY in 500 ml nonbaffled flasks. Cultures were incubated at 200 rpm at 30 °C for 24 h. After washing with 0.9 % NaCl, the pellets were resuspended in BMMY and used for inoculation of 50 ml BMMY in 500 ml baffled flasks at a starting OD600 of 0.5. Cultures were grown at 20 °C, 200 rpm and supplemented every 24 h with 0.5 % (v/v) methanol.