UV Tube Technical Considerations

advertisement

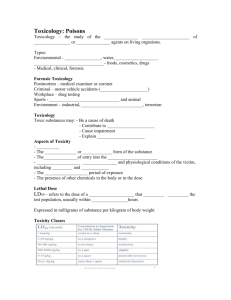

1 Scientific and Technical Aspects The UV-Tube uses an ultraviolet (UV) light bulb to inactivate microorganisms. This type of bulb is sometimes referred to as a “germicidal” bulb because it inactivates germs. A UV or germicidal bulb is similar to a fluorescent bulb, except that it lacks the internal phosphor coating and is housed in fused quartz rather than glass. 1.1 Ultraviolet Light Ultraviolet light is of shorter wavelength (higher energy) than visible light. It is called ultraviolet because it is just beyond violet light. Officially, ultraviolet light is defined to be any wavelength of light – also called electromagnetic radiation – shorter than 400 nanometer UVB 280-315 UVA UVC 315-400 200-280 400 Wavelength (nm) X-Rays Ultraviolet 700 Visible Infrared Microwaves Radio Ultraviolet light is also emitted by the sun. The UVA and UVB (280-400nm) are responsible for sun tanning and sun burning. UVC, which is almost entirely filtered out through the atmosphere, can penetrate cells and cause damage to the DNA. This damage leads to the inactivation of microorganisms in drinking water. NOTE: For the same reason that UVC is harmful to microorganisms, it can be harmful to humans as well. UVC can cause skin irritation and severe eye damage. For this reason, never look at the bulb when it is on. Direct exposure can be avoided by never opening the UV-Tube when it is plugged in to the power source, whether or not the light is on. The UV-Tube design uses a Plexiglas or glass window that completely filters out all UVC, leaving only harmless blue light. (See section on material interactions with UV light for more information on UVC penetration through plastics.) 1.1.1 D isinfe ction by UV 1.1.1.1 Biological Effects of UV UVC light inactivates microorganisms by damaging their genetic material (DNA) and rendering them unable to reproduce. DNA (deoxyribo nucleic acid) is essentially two intertwined strands with base pairs attached. The two strands are unwound and copied during replication of the cell. Ultraviolet light in the UVC region interacts with the DNA to create photoproducts. The most common photoproducts are created when two bases on the same strand become connected. When enough of these pairs (along with other photoproducts) are created, replication of the DNA is prevented. The maximum absorption of DNA – and maximum formation of photoproducts – occurs between 260265 nm. In this manner, UVC is capable of inactivating bacteria, viruses, fungi, spore forming organisms, and even cyst forming protozoans. Photoproducts are formed by the pyrimidine bases (thymine, cytosine and uracil) at a much higher rate than by purine bases (adenine, guanine) The most common photoproducts are cyclobutyl dimers, which are formed when two adjacent pyrimidine bases join to form a four carbon ring. Although pyrimidine dimers are often composed of two thymines, they may also be composed of two cytosines, or a thymine and a cytosine. Other, less common photoproducts include pyrimidine adducts, spore photoproducts, pyrimidine hydrates and DNA-protein crosslinks (Harm, 1980). 1.1.1.2 Disinfection Byproducts UV treatment, unlike chlorination1, produces no known disinfection byproducts (de Veer et al., 1994; National Drinking Water Clearinghouse, 2000; Wolfe, 1990). Similar to the UV-Tube, chlorine also kills microorganisms. However, chlorine can bind with organic materials in the water forming potentially hazardous compounds, called disinfection byproducts. 1.2 Theory Behind the UV-Tube To inactivate a given microorganism, the water must be exposed to a certain amount or dose of UV light. Dose is determined by variables associated with the design and operation of the UVTube, as well as the characteristics of the water that is treated. 1.2.1 Dose Calculation Within the UV-Tube, dose is calculated as the product of light intensity at a given wavelength and exposure time. Intensity at any given point is determined by bulb strength and the geometry of the reactor. The greater the thickness of water that the light travels through, the lower the intensity received. The exposure time is governed by the geometry and the hydrodynamics of the reactor. The UV-Tube is designed such that the lowest dose received by any of the water is sufficient to achieve the desired reduction in microorganisms. Dose is commonly measured in mW-sec/cm2 (equivalent to mJ/cm2). Standard doses delivered by a UV drinking water treatment system are between 15 and 50 mW-sec/cm. The EPA has not finalized a rule on dose requirement. Intensity decreases due to attenuation and dissipation. In other words, as one moves further from the source, the strength of the light decreases because it is spread over a larger area (dissipation) and because the light interacts with molecules in the water (attenuation). While dissipation is predicted simply by the geometry of the UVTube, attenuation depends on characteristics of the water. If the water contains a high concentration of materials that absorb UV light, then less UV will be transmitted. The amount of Energy Power Intensity Units Equivalents Joule (J) Watt (W) 1 J/s mWs/cm2 1 mJ/cm2 = 103 μWs/cm2 = 10 J/m2 For discussion of disinfection byproducts created by chlorine, see EPA “Alternative Disinfectants and Oxidants Guidance Manual”, sections 2.3.1- 2.3.3, pages 56-62 EPA, 1999. Alternative Disinfectants and Oxidants Guidance Manual, United States Environmental Protection Agency, Office of Water. 1 light that is absorbed per centimeter is expressed as the absorption coefficient. As this coefficient increases, transmissivity of the UV light through the water decreases exponentially, so the absorption coefficient of the water plays an important role in the effectiveness of the UV disinfection device. 1.2.2 Design and Use Factors Affecting Performance 1.2.2.1 Flow Rate The higher the flow rate, the smaller the dose received by the water. An appropriate flow rate must be determined based on the characteristics of the water and on the desired dose. 1.2.2.2 Suspended particles, Particle Associated Microorganisms & Turbidity Turbidity is a measure of the quantity of particulates in a solution. It is determined by shining an infrared beam of light through a one centimeter sample and measuring light detected by sensors placed at ninety degrees to the beam. Turbidity is not necessarily correlated with the absorption coefficient (see below). Turbidity is commonly reported in NTU. Turbidity is often thought to be a limiting feature in ultraviolet disinfection. However, investigations have shown that particles, as long as they are not UV-absorbers, do not significantly reduce the overall irradiance by either shading or scattering, but only when organisms are embedded within them (Emerick et al., 1999; Linden and Darby, 1998, p.215) Particle suspension can increase the apparent absorption coefficient – as measured by a spectrophotometer – by scattering rather than absorbing light (Linden and Darby, 1998, p.214). This effect can lead to under prediction of design capabilities. In the US this would only be a concern in wastewater treatment, however in developing country applications, high particle concentration may be relevant in drinking water as well. 1.2.2.3 Absorption Coefficient of Water The absorption coefficient (α) describes how much light is lost as it travels through a medium. It can be determined experimentally and is reported in inverse centimeters. The absorption coefficient of pure distilled water is close to zero. Natural organic matter, iron, nitrate and manganese absorb UVC light and will increase the absorption coefficient of a water sample (Kolch, 1999). Absorption coefficients in drinking water would be expected in the range of 0.01 to 0.2. The Absorbance of 7 drinking water samples taken around the Pátzcuaro region were in the range of 0.002 to 0.009, which correspond to absorption coefficients between 0.005 and 0.021 cm-1 (base e). One sample, taken from a muddy puddle, had an Absorbance of 0.048, or an absorption coefficient of 0.111 cm-1(base e). According to Snicer et al., water with an absorption coefficient of 0.125 would be considered of fair water quality (1997, p.22). Just as the recommended dose has not been standardized, neither have allowable levels of UV absorbing compounds. However, maximum concentrations of iron and manganese have been recommended at 0.03 mg/l and 0.02 mg/l, respectively (Kolch, 1999) and turbidity less than 5 NTU (Bolton, 2001). The issue of turbidity and particulate concentration is discussed below. 1.2.2.4 Water Depth For a given sized UV-Tube, determining the best water depth (or weir height) involves a tradeoff between residence time and water thickness. The higher the water height, the greater the volume of water in the tube at any given flow rate and therefore the greater the average residence time. However, the higher the water height, the greater the attenuation of light and the lower the dose reaching the water at the very bottom of the tube. Since attenuation is proportional to the absorption coefficient, the optimal water height will depend on the absorption coefficient. As can be seen in the figure below, the optimal weir height (or water depth) is inversely related to the absorption coefficient. Optimal Weir Height as Function of Absorption Coefficient Weir Height (cm) 7.0 6.0 5.0 4.0 3.0 0 0.1 0.2 0.3 0.4 0.5 Absorption Coefficient (cm-1) 1.2.2.5 Proper Usage The UV-Tube is designed to require limited user maintenance, however if certain practices are not followed, the effectiveness can be reduced substantially. Users should always be sure that the UV-Tube is turned on and that blue light is shinning through the window. If the UV-Tube is turned off, users must allow the bulb five minutes to warm up before drinking the water. (Within the first five minutes bulb output increases about 20%. 1.2.2.6 Bulb Types The maximum UV absorbance of DNA, 260-265 nm, coincides well with peak output of low pressure mercury arc lamps at 253.7 nm. Two different types of lamps are typically used in water disinfection, medium pressure and low pressure mercury vapor arc lamp. The table below displays these differences. UV Lamp Types Characteristic Typical Energy Use: Percentage Output at 253.7 nm: Low Pressure / Low Intensity 60 W 88% Medium Pressure / High Intensity 5,000 W 44% Ozone Production: NONE Possible, quartz can be doped to prevent formation Susceptibility to Cooling: Suited for Water Quality Type: Benefits: YES Good More efficient NO Bad Smaller, Less maintenance 1.2.2.7 Bulb Strength Dose received depends on bulb strength. approximately 5 Watts at 254 nm. A 30 Watt low pressure GE T8 bulb emits As the bulb ages its strength will slowly diminish. GE recommends a replacement after 7,500 hours, assuming bulb is turned on for 3 hour periods. Each start decreases the bulbs’ lifetime, so if the bulb is left on for periods greater than 3 hours, it will last longer. For the UV-Tube we recommend that the bulb be left on at all times and be replaced after one year. 1.2.2.8 Tube Length The tube length is dictated by the bulb length. A 30 Watt, 36 inch bulb works well in a tube that is about 104 centimeters long. The longer the tube (and bulb), the longer the residence time and therefore the greater the dose. 1.2.2.9 Tube Width Tube width, like tube length, increases the residence time of the water and therefore increases the dose. The four inch inner diameter width was chosen because it large enough to provide a good dose, without being so large as to be inconvenient in the kitchen. 1.2.2.10 Tube Material The tube material may affect the flow dynamic and the amount of reflection. Preliminary model calculations assume that there is no reflection, i.e. total absorption on all sides. This is a safe assumption, because it underestimates dose. 1.3 Measurements of Design Criteria 1.3.1 Turbidity Turbidity can be measured by a portable turbidity meter. One model can be purchased from Hach Company for approximately $300. 1.3.2 Absorption coefficient A spectrophotometer measures the absorbance (A) of a sample by passing light at 254nm through a one centimeter quartz sample cell, containing water sample and measuring the intensity of light going in (Io) and that coming out (I). I A I0 l The absorption coefficient (α) is related the intensity by the equation: I I 0 e If the path length (l) is equal to one, as it is in the spectrophotometer, then the absorption coefficient is related to the absorbance according to the following equation: A 2.303( A) log( e) Since there is no easy way to measure it in the field, it is best to bring a number of samples back to the laboratory. Only 10 ml is needed for this analysis, so many small samples may be taken. 1.3.3 Log Removal Pathogen inactivation is measured in terms of log removal. If the concentration coming in is 106 CFU (colony forming units)/100ml and the concentration coming out were 103 CFU/100 ml, then, by subtracting the exponents, we see that the log removal is 3. This is equivalent to a 99.9% reduction. See example below. Inlet: 106 CFU/100ml Outlet: 103 CFU/100ml Reduction = (106 CFU/100ml – 103 CFU/100ml) = (1,000,000 – 1,000) = 999,000 Percent Change = (Inlet – Outlet) x 100 = (999,000) x (100) = 99.9% reduction Inlet 1,000,0000 1.3.4 Flow rate The flow rate from the same source is likely to be variable. Be sure to ask about the variability and return during times when it is expected to be highest. If you have a container of known volume and a stop watch, just fill up the container – with valve all the way open – and time it. It is useful to repeat this procedure a couple of times. 1.4 Material Interactions with UV light Because UV light is short wavelength and high energy, it has the capacity to breakdown some materials. Experimental research in the literature is generally concerned with degradation from sunlight and is therefore limited to experimentation with UVA and UVB (280-400nm). Although the type and degree of degradation is likely a function of the wavelength, we assume here that degradation in the UVA and UVB range is at least an indicator of potential degradation in the UVC range. As it turns out, the degree of degradation is generally found to be inversely proportional to wavelength. Andrady et al. report a linear relationship between the logarithm of the damage and wavelength of exposure (1998, p. 101) However, others point out that the distribution of UVA, UVB and UVC could have “unexpected consequences” (Camilleri, 2000, p.77). Finally, although considerable effort has gone towards understanding both how to stabilize against and improve the breakdown of materials in the presence of sunlight, little analysis of expected final breakdown products exists, at least for plastics. 1.4.1 PVC pipe Polyvinyl chloride (PVC) will breakdown under all types of ultraviolet light (UVA, UVB and UVC). To slow this breakdown and prevent the release of hazardous breakdown products into the water, UV-Tubes constructed with PVC pipe must be lined with a stainless steel or galvanized steel tray. 1.4.2 Galvanized Steel Galvanized steel is steel coated with a zinc layer that will preferentially corrode, so as to protect the steel. For the purpose of the UV-Tube, galvanized steel is a durable, accessible and inexpensive liner. At the edges where the fabricated steel has been cut, zinc will be released into the water. The release of zinc seems to be accelerated by exposure to UV. The release of small amounts of zinc is likely not to be a concern, as the taste threshold is lower than the health limit. The taste limit would only be reached if water were left under the light for about a week, and then consumed. Flushing would eliminate this problem. 1.4.3 Stainless Steel Stainless steel is inert to UV light. It is the material often used in the design of commercial systems. Where available, it is the best option. Sheets of it may be bent and used to line a PVC tube, or construct an entire system. 1.4.4 Silicon Sealant Silicon glue intended for windows or roofing has UV resistance and is therefore considered appropriate for sealing the UV-Tube, at this time. 1.4.5 Plastic or Glass Windows Plastic and glass tend to be opaque to UV light. Although transmission varies with wavelength and thickness of material, even the very thin (a few millimeters thick) Plexiglas windows block out 100% of the potentially dangerous UVC light. However, after prolonged exposure to UV, we observed some clouding of the plastic. If possible, glass windows would be preferred. 1.5 Risks 1.5.1 Exposure to UV-C radiation As mentioned, UVC can cause skin and eye damage. It is important to never look at the UV bulb or expose to the light. 1.5.2 Electrical Shock Similar to any electrical appliance, there is risk of electric shock from the UV-Tube. Care should be taken to secure all wires and secure ballast inside of smaller tube. UV-Tube should be unplugged before performing any maintenance. 1.6 Limitations The UV-Tube, like any water purification product, is only one part of an integrated effort to improve water-related health. Access to water supply, improved sanitation, and prevention of recontamination must accompany water purification to most effectively reduce water-related disease. There are, of course, numerous other health concerns with drinking water that are non-biological and therefore unaffected by treatment with UV light. Some of these are longer term risks, but some, such as very high arsenic or lead levels, can have more immediate effects. Consider the water source, the quality and other treatment methods in conjunction with the UV-Tube. 1.6.1 Highly Turbid Water/High UV Absorption Coefficient Water with very high turbidity or a high UV absorption coefficient may not be able to be treated by the UV-Tube. Filtration can reduce turbidity and may decrease the absorption coefficient. 1.6.2 Storage Capability The water exiting the UV-Tube should always be collected in clean containers. Any microorganisms present in a container could contaminate the UV treated water, making it unsafe to drink. Containers that have been washed with UV-treated water and allowed to dry thoroughly or containers that have been washed in chlorinated water can be considered safe to use. Unlike chlorination, which leaves a residual disinfectant, UV disinfection has no residual; water should not be stored after UV treatment. For this reason, the UV-Tube is designed to be used as a flow-through system to treat water as it is needed. There is also be an issue with the bacteria repairing their damaged DNA allowing them to successfully replicate. This does not appear to be a great concern, however it is one more reason why storage of UV treated water is not recommended. 1.6.3 Access to Reliable Electricity The UV-Tube is designed for households with reliable electricity supplies. In its most basic design, the UV-Tube would remain on for 24 hours per day, using just under 40 Watts. The window is intended to act as a safety mechanism; if no blue light comes out of the window, users should be educated to not drink the water. Slightly more expensive and more complicated UV systems could be built to work with intermittent electricity supplies – from unreliable grid electricity or household photovoltaic (PV) systems. To reduce the power consumption of the UV-Tube, it could be cycled on during times of peak usage and off at night. However, such a system would require more community education regarding bulb warm up times and bulb life, and could lead to users mistakenly drinking unsafe water from an unlit UV-Tube.