DRAFT

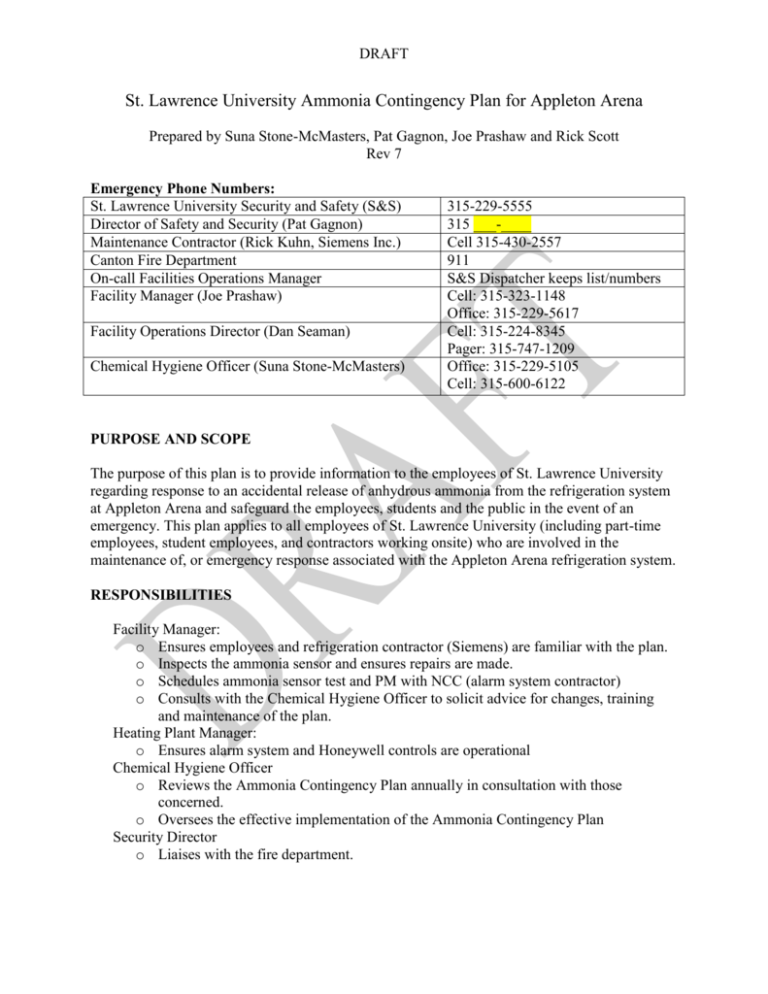

St. Lawrence University Ammonia Contingency Plan for Appleton Arena

Prepared by Suna Stone-McMasters, Pat Gagnon, Joe Prashaw and Rick Scott

Rev 7

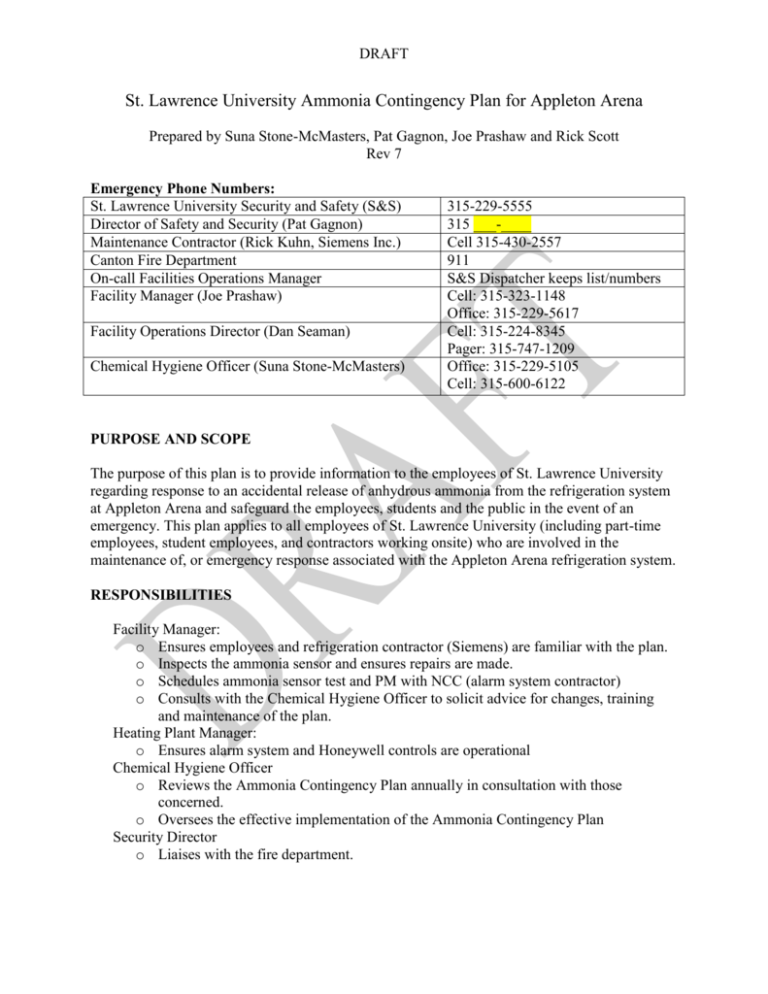

Emergency Phone Numbers:

St. Lawrence University Security and Safety (S&S)

Director of Safety and Security (Pat Gagnon)

Maintenance Contractor (Rick Kuhn, Siemens Inc.)

Canton Fire Department

On-call Facilities Operations Manager

Facility Manager (Joe Prashaw)

Facility Operations Director (Dan Seaman)

Chemical Hygiene Officer (Suna Stone-McMasters)

315-229-5555

315 ___-____

Cell 315-430-2557

911

S&S Dispatcher keeps list/numbers

Cell: 315-323-1148

Office: 315-229-5617

Cell: 315-224-8345

Pager: 315-747-1209

Office: 315-229-5105

Cell: 315-600-6122

PURPOSE AND SCOPE

The purpose of this plan is to provide information to the employees of St. Lawrence University

regarding response to an accidental release of anhydrous ammonia from the refrigeration system

at Appleton Arena and safeguard the employees, students and the public in the event of an

emergency. This plan applies to all employees of St. Lawrence University (including part-time

employees, student employees, and contractors working onsite) who are involved in the

maintenance of, or emergency response associated with the Appleton Arena refrigeration system.

RESPONSIBILITIES

Facility Manager:

o Ensures employees and refrigeration contractor (Siemens) are familiar with the plan.

o Inspects the ammonia sensor and ensures repairs are made.

o Schedules ammonia sensor test and PM with NCC (alarm system contractor)

o Consults with the Chemical Hygiene Officer to solicit advice for changes, training

and maintenance of the plan.

Heating Plant Manager:

o Ensures alarm system and Honeywell controls are operational

Chemical Hygiene Officer

o Reviews the Ammonia Contingency Plan annually in consultation with those

concerned.

o Oversees the effective implementation of the Ammonia Contingency Plan

Security Director

o Liaises with the fire department.

DRAFT

GENERAL

The ice rink is open between August 20 and March 20. The ammonia system is located in the

compressor room in Appleton Arena which is accessed from the north parking lot through the

large overhead door or through the interior hallway. The refrigerant system has two compressor

units, which are regularly maintained. It contains 300 lbs. of anhydrous ammonia (NH3). Three

additional cylinders holding a total of 300 pounds of anhydrous ammonia are also stored in the

compressor room. Drawings of Appleton Arena with refrigeration system layout are in

Appendix A.

AMMONIA ALARM SYSTEM

The compressor room is equipped with a gas sensor for detection of ammonia leaks which is

mounted on the electrical panel to the right of the compressors.

The system alarm works as follows:

1- The alarm will activate an audible and strobe alarm by the compressor room overhead door

when the ammonia concentration reaches 75 ppm. This alarm is a warning to evacuate Appleton

Arena. In addition, the alarm will report to the Security Office via an autodialer, access control

system and the fire alarm panel. Employees may not enter the compressor room once the

alarm has been activated.

If an ammonia smell is detected outside Appleton Arena, emergency phones located in the

Appleton office at the opposite end of the building, can be used to inform Safety and Security

(x5555)

If the alarm system malfunctions the facility manager will take immediate steps to return it to

service and advise Safety & Security, EH&S and all Appleton staff that the system is out of

service.

RESPONSE

Upon activation of the alarm, the Safety & Security dispatcher is alerted and will in turn

immediately contact the County dispatcher at 911 and send a patrol officer to the scene to assist

as directed. Safety & Security will dispatch the Maintenance Contractor and the Facility

Manager. They will next contact the Director of Facilities Operations. Selected SLU staff (per

the Facilities Management Call-In Protocol) will also be notified by the dispatcher as soon as

possible after the response has been initiated.

All building occupants will evacuate the space regardless of any event in progress. The Incident

Commander (or their designee) will be in charge of the response and direct any evacuation of the

building and outside area. Emergency evacuation routes are posted throughout the building.

Security and Facilities staff working in the arena shall remain available to assist in directing the

DRAFT

evacuation by posting themselves at the exits of the building. Staff not on duty may be called in

to assist in the event of a serious emergency.

An emergency ammonia release valve and refrigeration equipment power shut-off switch are

located in a locked red box mounted 8 feet up on the west wall, adjacent to the exterior

Compressor room door. (See photo in Appendix A.) In case of an emergency, Canton Fire &

Rescue or the St. Lawrence County Hazmat Team will open the valve and shut down the system.

An event such as a major fire near the compressor room or a large discharge from the ammonia

refrigeration system poses a health hazard to people in the vicinity. The Incident Commander,

most likely the Canton Fire Chief, would decide on the need to activate the Village of Canton

Disaster Plan for an evacuation and activate the ammonia release valve. The map provided in

Appendix D delineates an isolation zone of 200 ft in all directions and an evacuation zone of

zone of 0.4 miles (DAY) or 1.4 miles (NIGHT) to safeguard people who could be affected from

a discharge from the ammonia refrigeration system.

COMPRESSOR SHUTDOWN

There are three (3) emergency shutdown switches for the system:

- In the compressor room; (see appendix B)

- Inside the emergency control box in the interior corridor, to the right of the compressor room

door; (see Appendix C)

- The Central Heating Plant

There are also four (4) yellow ammonia isolation valves located in the compressor room. See

Appendix B for a photo of these valves. A wrench for closing the valves is kept chained in reach

of the valves.

If the alarm sounds, any individual wearing proper PPE and trained to do so may shut down the

system.

NRC NOTIFICATION

The CERCLA (Comprehensive Environmental Response, Compensation, and Liability Act)

designated ammonia as a hazardous substance. The Reportable Quantity (RQ) is 100 lb. (45.4

kg). The Facility Manager, Director of Facilities Operations or Chemical Hygiene Officer is

required to notify the National Response Center (NRC) immediately when there is a release in an

amount equal to or greater than the RQ. Toll free (800) 424-8802.

REGULAR INSPECTIONS AND MAINTENANCE ACTIVITIES

From August 20th to March 20th the ice rink is open. The Facility Manager conducts daily visual

inspections of the ammonia compressor room, and completes a daily record report kept in this

DRAFT

room. After March 20th when the rink is closed, a technician from Siemans closes the valves.

Gas pressure in the compressors is continuously monitored in the heating plant year-round.

The ammonia sensor must be tested per Honeywell’s recommendations with certified calibration

gas every six months or after major exposure to a leak. See instructions and PM schedule in

Appendix E.

Conduct a response test once between calibrations, i.e. at three month intervals. Expose sensor to

ammonia/water solution to verify proper sensor response and alarm functions.

Employee Training and Exercises.

Any employee who may be involved in the maintenance of, or an emergency response associated

with, the refrigeration system must be trained and qualified for their responsibilities. These

employees include Grounds, Security, Skilled Trades, or other Facilities Management personnel,

and supervisors of those employees. New employees whose job requires them to work in the

arena shall be trained by their supervisor within one week of their arrival.

Trained employees shall undergo a brief annual refresher conducted and documented by the EHS

Manager to review the response plan and assess any changes noted in the course of the year. If

there are significant changes in the system, alarms or emergency response procedures, updated

training for all involved personnel will be conducted at the time of the changes.

In addition, certificates of training for Siemens contract employees, and an updated copy of their

contractual service agreement, are kept on file by Facilities Management.

NATURE AND HAZARDS OF AMMONIA

Ammonia (NH3) is a colorless gas, with a penetrating, pungent, and suffocating odor. It easily

dissolves in water to form a caustic solution called ammonium hydroxide (NH4OH), sometimes

referred to as aqueous ammonia. Ammonia has a vapor density less than air and will rise when

released, but it will readily react with moisture in the air, become heavier and sink to the ground

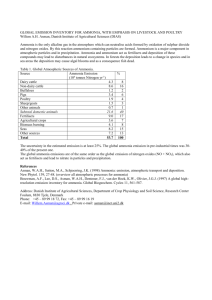

The table below describes some chemical characteristics of ammonia and ammonium hydroxide.

PHYSICAL CHEMICAL

PROPERTIES

Odor Threshold

pH

Vapour density

Colour and odor

Physical state

*TWA-TLV:

*STEL:

*IDLH:

*UEL:

*LEL:

AMMONIA

AQUEOUS AMMONIA

1-15 ppm

11.6

0.5967 of air density (air=1)

colorless pungent odor

gas

25 ppm

35 ppm

300 ppm

25% in air

16% in air

2-50 ppm

14

n/a

very pungent, choking

liquid

25 ppm

35 ppm

300 ppm

n/a

n/a

DRAFT

See acronymns, final page

RISKS

Inhalation of corrosive ammonia gas can cause irritation and inflammation of the respiratory

system, difficulty breathing, nausea, vomiting and chest pain. Irritation or burns may occur after

direct skin contact with anhydrous ammonia, solutions or concentrated ammonia gas. Direct

contact with ammonia with eyes may cause irritation, tearing, severe injury or blindness.

FIRST AID MEASURES

WHAT TO DO:

IN CASE OF

Ammonia (ammonium

hydroxide) on skin or in eyes

FIRST ACTION

SECOND ACTION

Immediately flush skin or eyes Bring victim to a physician.

with running water for at least

20 minutes. Occasionally lift

upper and lower lids of eyes.

Get victim into fresh air.

Bring victim to a physician.

Strong Ammonia fumes

inhaled

Refer to the Safety Data Sheet for anhydrous ammonia in Appendix E for further details.

An emergency shower and eye wash station is located in the Zamboni Room.

Any person from the University who requires medical assistance during the emergency must

follow up with the Risk Manager (Theresa Simoni, 229-5913) for further assessment and ensure

proper documentation of the event. The Incident Response Report must be filled out by the

employee’s supervisor (http://www.stlawu.edu/sites/default/files/resource/incident_report.pdf).

ACRONYMNS

TLV-TWA (Threshold Limit Value-Time Weighted Average): the concentration for a normal 8

hour workday and a 40 hour work week, to which nearly all workers may be repeatedly exposed,

day after day, without adverse effect.

STEL (Short Term Exposure Limit): the maximum concentration to which someone can safely

be exposed for a period of up to 15 minutes - with a maximum of four periods per day.

IDLH (Immediately Dangerous to Life and Health): concentrations which upon exposure are

likely to result in death or immediate or delayed permanent adverse health effects.

UEL (Upper Explosion Limit): the highest concentration of a vapor or gas which will explode,

ignite or burn in the presence of an ignition source. Mixtures above this limit are too rich to burn.

LEL (Lower Explosion Limit): the lowest concentration of a vapor or gas which will explode,

ignite or burn in the presence of an ignition source. Mixtures below this limit are too rich to burn.

MAINTENANCE OF THE AMMONIA CONTINGENCY PLAN

DRAFT

A review of the Ammonia Contingency Plan will be conducted annually to ensure contents are

current. A written copy of the Ammonia Contingency Plan is in the Department of Security and

Safety (76 Park St). It is electronically located on St. Lawrence University’s Environmental

Health and Safety web page (http://www.stlawu.edu/environmental-health-andsafety/environmental-health-and-safety-policies)

DRAFT

Appendix A – Appleton Arena Layout Drawing

Ammonia

vent

Compressor

room

Emergency

ammonia release

valve

Compressor

room door

Fresh air intake

Zamboni room

door

DRAFT

Appendiz B - Compressor shutoff (or is it ammonia isolation?) valves marked yellow.

Vent and fan

Ammonia sensor

Shutoff valves

Main shutoff

DRAFT

Appendix C –interior control panel with shutoff switches. To shut off, flip switches (UP?

DOWN?)

DRAFT

Appendix D – Evacuation Map of Campus and Canton

DRAFT

Appendix D cont.

DRAFT

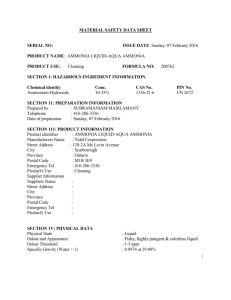

Appendix E – Anhydrous Ammonia Safety Data Sheet

DRAFT

Appendix F: Maintenance of ammonia sensors and alarm system

Preventative Maintenance will be performed as follows:

Honeywell ammonia sensor tested and calibrated with certified calibration gas, per

manufacture’s recommendations, every 6 months by outside contractor NCC. Documentation

will be provided to Facility Manager and EHS and maintained for no less than 3 years.

Honeywell ammonia sensor response test once between each calibration (3 months after each

calibration) performed by facility manager. Documentation in form of a checklist to be kept on

site for a minimum of three years.

Alarm system to be tested in accordance with New York State Fire Code by outside contractor

NCC. Documentation provided to EHS and maintained for a minimum of three years.

Ventilation fan to be tested in accordance with New York State Fire Code by outside contractor

NCC. Documentation provided to EHS and maintained for a minimum of three years.

Gas pressure sensor operation will be verified by the heating plant every 3 months (I don’t know

how often this should be done or how you can test it. Rick, any suggestions?)

Maintenance

For proper operation of the Honeywell ammonia meter it is essential that the test and calibration schedule be

followed. Honeywell Analytics recommends the following maintenance schedule:

• Calibration should be performed with certified calibration gas every six months or after major exposure to a

leak. Calibration kits are available from Honeywell Analytics.

• Response test once between calibrations, i.e. at three month intervals. Expose sensor to ammonia/water

solution to verify proper sensor response and alarm functions. Test more frequently in highly critical

applications. The response test is not required if multiple electro-chemical sensors are installed in the

same room.

All tests and calibrations must be logged.

Sensor Life: These electrochemical cells are extremely reliable, but several things can cause the cell

chemicals to become depleted including:

• a period of time,

• exposure to high temperatures,

• exposure to varying concentrations of the target gas,

• exposure to high moisture for extended periods without proper sensor enclosure.

CAUTION Although SensorCheck tests the sensor’s electrical viability every 24 hours, it is

TM

absolutely essential that these units be exercised with a gas sample on a regular and timely basis.

Typical sensor life in a refrigerated area will be three to four years. Typical life in a non-refrigerated area will be

one and a half to two years. Exposure to high levels of ammonia will shorten these times. In addition to timely

response checks, a preventative maintenance program of periodic cell replacement should be implemented.

When the cell becomes depleted, a replacement cell can be obtained from Honeywell Analytics. Simply unplug

the ribbon cable from the pins labeled Sensor, pull the old cell from the spring clip, discard the old cell and

replace it with a new one.

DRAFT

The sensor should be checked according to the following procedure after a five-minute warm-up period. Manning

EC-F9-NH3 Sensor 19546 ECF9NH3 07/09 REVE Copyright © 2009 Honeywell Analytics. All Rights Reserved. 19

http://www.instrumart.com/assets/Honeywell-Manning-EC-F9-NH3-manual.pdf

The Macurco low-level ammonia detector procured through NCC requires replacement of the

sensor every 2 years. Calibration is not required, as the unit uses on-board diagnostics. For

instructions see:

http://www.aerionics.info/files/Macurco_TX-6-AM_Manual_4-8-20132.pdf

DRAFT

Short Version Ammonia Response

*If the alarm goes off:

Security will receive autodial message and request HazMat response via 911.

Security will call Joe Prashaw, Dan Seaman, Suna Stone-McMasters and Siemens Technician

Evacuate Compressor Room.

Room will be vented automatically via ceiling fan unit, gas will discharge out roof.

If safe to do so, shut off compressors from heating plant or panel in interior hallway.

Begin evacuation of Appleton Arena.

*If ammonia escapes from compressor room (alarm sounds and odor

is present outside)

Check wind direction.

Evacuate Appleton Arena, guide evacuees upwind/away from ammonia plume, to safe zone 200

feet in diameter from compressor room.

Provide first aid to any person exposed to ammonia.

DRAFT

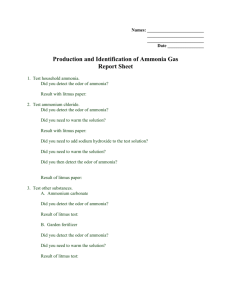

Appendix G – Weekly ammonia sensor check

Week of:

Date and

time checked

Initials of

person

checking*

Both Sensors in

service? Y/N

NCC and Safety & Security

contacted if sensor not in

service?

Y/N/NA

*JP=Joe Prashaw, ______________________________ Send completed form to EHS when

complete. Mail to: EH&S Office, Warehouse. 229-5913

DRAFT

Appendix H – Semi-Annual ammonia sensor test (using calibration gas)

Calibration/test Due April 30

Date and time checked

Name of person

checking*

Calibration gas expiration date,

Calibration gas expiration date

Manning calibration gas 1000 ppm Ammonia gas in air

Macurco AM-FCK: Gas Cylinder, 25 ppm Ammonia gas in air

Both Sensors in service?

Y/N

Readout at alarm:

LCD-NH3 sensor:

Manning EC-F9-

Readout at alarm: Macurco

TX-6-AM Sensor:

NCC and Safety &

Security contacted if

sensor not in service?

Y/N/NA

Alarm and strobes operate? Y/N

Signal received at Safety &

Security? Y/N

NCC and Safety &

Security contacted if

alarms/strobes/signal fail?

Y/N/NA

Calibration/test Due October 31

Date and time checked

Name of person

checking*

Calibration gas expiration date,

Calibration gas expiration date

Manning calibration gas 1000 ppm Ammonia gas in air

Macurco AM-FCK: Gas Cylinder, 25 ppm Ammonia gas in air

Both Sensors in service?

Y/N

Readout at alarm:

LCD-NH3 sensor:

Manning EC-F9-

Readout at alarm: Macurco

TX-6-AM Sensor:

NCC and Safety &

Security contacted if

sensor not in service?

Y/N/NA

Alarm and strobes operate? Y/N

Signal received at Safety &

Security? Y/N

NCC and Safety &

Security contacted if

alarms/strobes/signal fail?

Y/N/NA

*NCC representative.

Send completed form to EHS when complete. Mail to: EH&S Office,

Warehouse. 229-5913. Send NCC April report to same address.