Word

advertisement

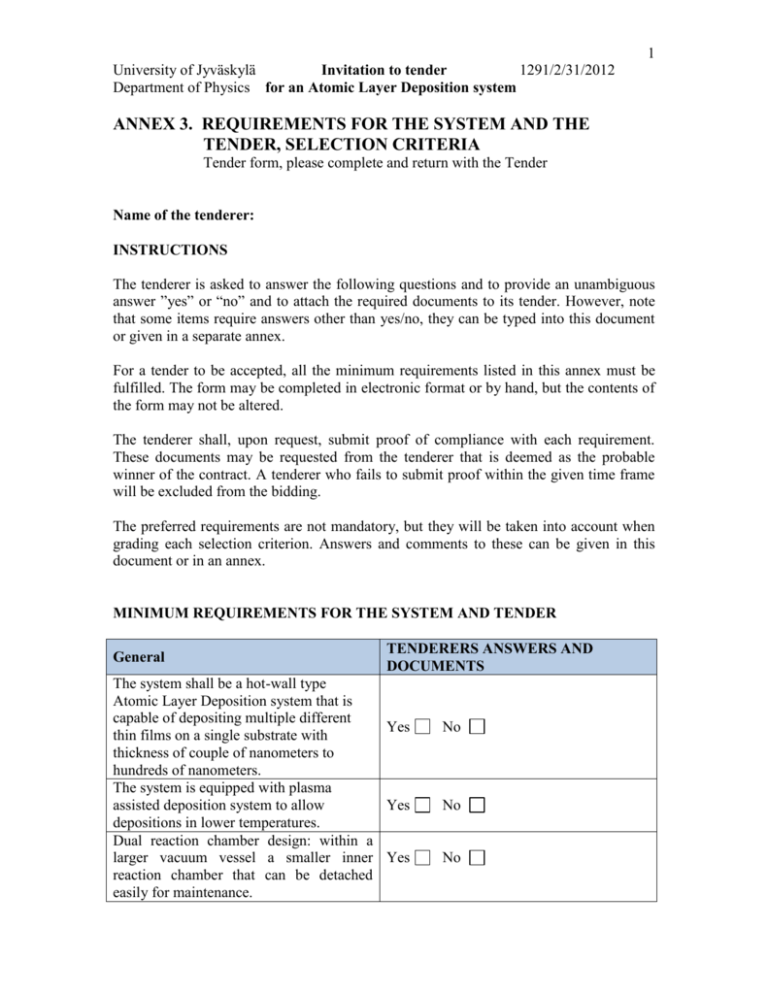

1 University of Jyväskylä Invitation to tender 1291/2/31/2012 Department of Physics for an Atomic Layer Deposition system ANNEX 3. REQUIREMENTS FOR THE SYSTEM AND THE TENDER, SELECTION CRITERIA Tender form, please complete and return with the Tender Name of the tenderer: INSTRUCTIONS The tenderer is asked to answer the following questions and to provide an unambiguous answer ”yes” or “no” and to attach the required documents to its tender. However, note that some items require answers other than yes/no, they can be typed into this document or given in a separate annex. For a tender to be accepted, all the minimum requirements listed in this annex must be fulfilled. The form may be completed in electronic format or by hand, but the contents of the form may not be altered. The tenderer shall, upon request, submit proof of compliance with each requirement. These documents may be requested from the tenderer that is deemed as the probable winner of the contract. A tenderer who fails to submit proof within the given time frame will be excluded from the bidding. The preferred requirements are not mandatory, but they will be taken into account when grading each selection criterion. Answers and comments to these can be given in this document or in an annex. MINIMUM REQUIREMENTS FOR THE SYSTEM AND TENDER General TENDERERS ANSWERS AND DOCUMENTS The system shall be a hot-wall type Atomic Layer Deposition system that is capable of depositing multiple different Yes thin films on a single substrate with thickness of couple of nanometers to hundreds of nanometers. The system is equipped with plasma assisted deposition system to allow Yes depositions in lower temperatures. Dual reaction chamber design: within a larger vacuum vessel a smaller inner Yes reaction chamber that can be detached easily for maintenance. No No No 2 University of Jyväskylä Invitation to tender 1291/2/31/2012 Department of Physics for an Atomic Layer Deposition system The equipment is class 1000 (ISO 6) clean room compatible. Yes No Ozone generator is included. Yes No Changeable process chambers for different sample sizes (see section for samples below). Time requirement for chamber change must be presented. Yes No Available options for precursor lines etc. are listed with prices in the tender. Yes No The pump line includes a particle trap between the reactor and a dry pump. Yes No Pumping speed of reaction chamber pump at least 300 m3/h. Yes No Base pressure of less than 5 Pa achievable in the vacuum vessel. Yes No SAMPLES The system shall be able to operate with following sample types and sizes: TENDERERS ANSWERS Standard silicon wafers with diameter up to 150 mm Yes No Small silicon chips, for example 1x1 cm2 Yes No Items with a maximum size of 100x100x90 mm3 Yes No Yes No Yes No Porous 50–100 µm thick structures similar to micro channel plates with high aspect ratios (up to 50–100). The system must be able to process samples with sensitive parts such as thin membranes without breaking them (for example during pump-down). Time estimate:_____min PROCESSES TENDERERS ANSWERS The system shall be able to process at least the following materials: Oxides: Al2O3, TiO2, ZnO, SiO2, Ta2O5, Yes No 3 University of Jyväskylä Invitation to tender 1291/2/31/2012 Department of Physics for an Atomic Layer Deposition system HfO2, MgO Nitrides: TiN, NbN, BN, AlN, SiN, TaN Fluorides: MgF2 Metals: Ru, Ag, Pt, W ALD and PEALD processing possible in one process sequence without changing hardware configuration to allow deposition of nanolaminates of ALD and PEALD films. Yes No Process temperature range 80–500 °C Yes No Source temperature up to 200 °C Yes No Installation of at least six gas, solid or liquid sources possible (in total) Yes No Compatibility with chloride-based reactants in long-term use. Yes No WARRANTY, MAINTENANCE TENDERERS ANSWERS AND DOCUMENTS Minimum 1 year warranty for all parts of the system. The supplier must guarantee that the service, spare parts and other maintenance are available for at least five years after the purchase. A list of commonly needed spare parts, their estimated consumption and their prices are included in the quotation. Most common spare parts are available in stock from the tenderer and can be shipped to the buyer’s facility within 36 hours. Free software updates during the warranty period. Reactor safety assessment document is delivered with the tool. This document includes a description of tool response to any abnormal operation conditions that can be expected to be encountered over the first 10 years of operation. During the warranty period the tenderer Yes No Yes No Yes No Yes No Yes No Yes No Yes No 4 University of Jyväskylä Invitation to tender 1291/2/31/2012 Department of Physics for an Atomic Layer Deposition system provides on-site technical and maintenance support within 72 hours of a request from the buyer. Weekends and public holidays are excluded from this time. During the warranty period the response time for telephone or e-mail support does Yes not exceed 8 hours during normal office hours. No Remote support is free of charge. Yes DELIVERY, INSTALLATION, TRAINING TENDERERS ANSWERS AND DOCUMENTS Delivery time not longer than six months. Yes No Yes No Yes No Yes No Yes No Yes No Installation documentation is provided at least four weeks before the delivery of the tool. This includes a description of the required infrastructure such as gas lines, connectors, electricity, exhaust, cooling, etc. Other technical documents and manuals including component charts and circuit diagrams must be delivered at the time of installation. The documentation includes instructions for maintenance of the reaction zone parts and plasma source by the buyer’s trained personnel. The tenderer is responsible for the installation and commissioning of the tool. The buyer is responsible for the connection of the tool to the facility support systems. End-user training must be provided at buyer’s site. Training of proper maintenance of the tool is included. A safety interlock list (both hardware and software) is provided with the tool. No 5 University of Jyväskylä Invitation to tender 1291/2/31/2012 Department of Physics for an Atomic Layer Deposition system 1. SELECTION CRITERIA: PRICE (50 POINTS) Please fill the form in Annex 4. Preferred requirements - - - If it is recommended that some of the planned processes should not be done in the same process chamber, the tender should include at least two chambers for each process type. The tender should also state if some of the planned materials cannot be used in the same source line due to risk of cross-contamination, and a quote for the parts that need to be changed when switching between such materials should be included. A quote for a possible option that can improve the performance for depositing films on high aspect ratio structures. Tenderer’s answer (or annex): 2. SELECTION CRITERIA: TECHNICAL REQUIREMENTS AND PERFORMANCE (30 POINTS) Performance test Two reference samples are required: 1) A 200 nm Al2O3 film deposited on a 150 mm wafer with about 400 nm thick PMMA layer on it, the deposition temperature should not exceed 100 °C. 2) A 100nmTiN/50nmAl2O3/Si film structure on a 150 mm Si wafer. Wafers for the tests will be sent from Jyväskylä by request and full wafers should be returned to Jyväskylä before the ending of this tender. The samples should be shipped to address: Timo Sajavaara University of Jyväskylä, Department of Physics Survontie 9 40500 Jyväskylä Finland The exact process parameters need to be given with the samples. The composition, resistivity and other properties of the films will be characterized in Jyväskylä. 6 University of Jyväskylä Invitation to tender 1291/2/31/2012 Department of Physics for an Atomic Layer Deposition system Preferred requirements - - Better performance (temperature range, pumping speed, number of precursors etc.) than in the minimum requirements. It is preferred that the vacuum pumps are placed in the service corridor outside the cleanroom, if possible. It is preferred that the small chips can be placed on a carrier without the need for clamping or gluing. No shortcutting in the plasma head: the reactor has proven capability of depositing thick layers (at least 4 µm) of conductive films by PEALD process without maintenance. A list of recommended gas alarm sensors. The buyer has a central gas alarm system that will be used also around ALD equipment The tenderer should declare to which extent they will provide the buyer with their current process library and will any new processes developed in the future be disclosed to the buyer. Tenderer’s answer (or annex): 3. SELECTION CRITERIA: DELIVERY TIME, TRAINING, WARRANTY, MAINTENANCE AND SPARE PARTS (20 POINTS) Preferred requirements - Delivery time shorter than 6 months will be considered beneficial. Software updates free of charge for at least three years. The tenderer should declare whether the production of the offered system will continue, or whether it will be replaced by a newer model in the near future. - A warranty period of two years or longer will be considered beneficial. - Emergency visit response time: during the warranty period on-site maintenance support is provided within 36 hours of request, excluding weekends and public holidays. Tenderer’s answer (or annex):