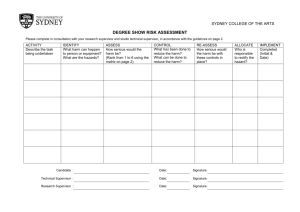

Risk Assessment Guidelines - SOM007

advertisement

SOM007 RISK ASSESSMENT GUIDELINES A RISK ASSESSMENT a systematic assessment of the hazards of a task and their potential to cause harm in light of the control measures in place. (See risk assessment form below to identify where the information must go) HAZARDS - are the sources of danger RISKS - are the possibilities of these hazards causing loss or injury 1. WHERE IS THE TASK TO BE DONE? 2. DESCRIBE THE TASK. What is the title of the task? (Keep it brief) Describe the procedure – brief overview of task e.g. Making a cup of tea, Fill electric kettle with cold water then boil water, pour boiling water into teapot. 3. WHAT ARE THE HAZARDS AND POSSIBLE HARM OF THE TASK? Identify all the hazards involved in the task and potential harm, even those where you think the risk to cause harm is insignificant. Make sure all aspects of the task are covered. For a list of potential hazards suggested possible harm see Appendix A. Some hazards require an additional specific safety assessment: Hazard – if this hazard is present then – additional ‘Associated Assessment’ required Chemical Biological Noise Lifting, moving, handling Laser Radiation COSHH assessment COSHH assessment + Biological assessment (possible) Noise assessment Manual Handling assessment Laser risk assessment Radiation assessment e.g. Making a cup of tea – hazards are electricity and heat, i.e. you could get an electrical shock from either a faulty kettle or from water coming into contact with the electrical current, or you could burn yourself by touching the hot kettle or scold yourself by coming into contact with the boiling water or steam. 4. WHO IS INVOLVED OR MAY BE HARMED? Who might be harmed? Identify and consider ALL persons who are likely to be at risk and determine their level of competency and potential for being harmed and the amount of supervision. Does the risk change depending on the persons involved? Persons to who may be involved: Staff - Academics, Academic Related, Academic Assistants, Post Docs. Technicians, etc. Post Graduate Students. Undergraduate Students, young inexperienced workers will need more supervision/training. Contractors. Visitors. Cleaning staff, security, which may also be present out-of-hours. Public and the environment If a child was making a cup of tea then the degree of risk, i.e. the potential for harm, is much higher than that for an adult making a cup of tea. This is for several reasons such as familiarity with the task and knowledge of the task and its hazards, i.e. competency, also the seriousness of an injury due to size difference between a child and an adult will influence the level of risk. ivan.easdon@manchester.ac.uk (School Senior Safety Advisor) room C15, Materials Science Building, Ext. 63596 1 SOM007 5. WHAT CONTROL MEASURES ARE CURRENTLY IN PLACE TO REDUCE HARM AND CAN ANY MORE CONTROL MEASURES BE INTRODUCED TO REDUCE HARM Look at the current control measures and always consider what additional control measures can be adopted to minimise the harm from each hazard. Some possible control measures: Training Supervision Instruction Information Barriers to create a safe zone Guards, fixed, interlocking or trip device Signs Safe systems of work Personnel Protective equipment (PPE) Maintenance and servicing Inspection and testing 6. WHAT ARE THE RISKS INVOLVED WITH EACH HAZARD? When deciding the risks involved in the task, consider likelihood, severity, frequency, duration, who is involved and the effect of each hazard to cause harm. Likelihood - How likely will the hazard cause harm? Severity - What would the severity of the harm be? What are the likely injuries? Who could be involved? Frequency - How often is the task being done? Does this affect the potential for causing harm? Duration - How long does the task take? Does this affect the potential for causing harm? Does the hazard change during the task? Effect – What is the potential effect to the operator and those around caused by the hazard? 7. RISK ASSESSMENT SCORE Risk assessment score is a subjective assessment based on the probability and severity of a hazard. Risk Assessment Score = Probability x Severity Score 4 3 2 1 Probability Probable Possible Remote possibility Virtually impossible Severity Fatal or injury or illness causing long term or permanent absence from work Major injury or illness, causing greater than 3 days absence from work Minor injury or illness, causing up to 3 days incapacity from work Minor injury or illness, causing no absence from work The aim is to minimise the Risk Assessment Score for each hazard, that way reducing the risk of harm of the task either by reducing the probability score or severity score. If probability or the severity has a value of 4 – stop work immediately and review control measures, can the risk of harm be reduced? If Risk Assessment score is 16 – stop work immediately, review control measures & seek advice from supervisor and safety advisor – do not proceed. If Risk Assessment score is greater than 12 - stop work and review control measures to try to reduce risk, monitor regularly, and consult your supervisor and safety advisor. If Risk Assessment score is 8 or 9 - review control measures to try to reduce risk. If Risk Assessment score is less than 8 - low priority but should still try to reduce risk. e.g. Pouring boiling water from a kettle to make a cup of tea – for an adult the severity might be a 1, but for a child it could be a 3, possibly a 4. So a control measure could be to forbid children handling a boiling kettle and so reducing the potential for harm. ivan.easdon@manchester.ac.uk (School Senior Safety Advisor) room C15, Materials Science Building, Ext. 63596 2 SOM007 8. OUT-OF-HOURS AND LONE WORKING Normal Out-of-hours working for researchers is defined as any time before 7.30 am and after 5.00 p.m. (1700 hours) Monday to Friday, all day Saturday and Sunday, and public holidays and between Boxing Day and New Years Day. Working between the hours of 11 p.m. (2300 hours) and 7.30 a.m. is not allowed without additional express permission from the supervisor and the School Safety Advisor and is termed ‘night-time working’ also no lone working is permitted during this period. Days Times Description Monday to Friday Monday to Friday Monday to Friday 7.30 a.m. to 5 p.m. 5 p.m. to 11 p.m. 11 p.m. to 7.30 a.m. Normal Working hours Out-of-Hours Working Night-Time working Weekend + Public Holidays + University closure days Weekend + Public Holidays + University closure days 7.30 am to 11 p.m. Out-of-Hours Working 11 p.m. to 7.30 a.m. Night-Time working Additional Requirements Nothing Out-of-Hours Permit Out-of-Hours Permit and additional express permission ‘Pairs rule’ applies Out-of-Hours Permit Out-of-Hours Permit and additional express permission ‘Pairs rule’ applies Lone working is defined as working alone (beyond earshot) for long durations without any contact or conducting a task with an unacceptable risk for lone working. This can be either outside normal working hours or during the normal working day. If Out-of-Hours and/or lone working are authorised then any additional restrictions, control measures or safety precautions must be identified in the safety assessment, under “hazards and risks”. NOTE: If Lone working or Out-of-Hours working – Worker must ALWAYS have available a means of distant communication, e.g. mobile phone with University Security’s number 0161-306-9966 in the mobile phone’s address book or on speed dial, or 69966 on an internal phone. Risk assessment only assesses the task and not the individual. Individuals must personally get authorisation from their supervisors to do task(s) Out-of-Hours and/or Lone Working (see SOM016). 9. OUT-OF-HOURS WORKING PERMIT All equipment that needs to be working out-of-hours must have an ‘Out-of-hours Working Permit’ – SOM035. The equipment but first be risk assessed for out-of-hours working with any additional restrictions for out-of-hours use identified. e.g. sample removal from a muffle furnace is allowed out-of-hours if sample is below 200°C if unaccompanied, or a piece of equipment can be used out-of-hours but the attached gas cylinder cannot be changed. Permits can be obtained from the Safety Advisor, Technical Service Manager and Technical support staff. The permits indicate what the equipment is, what services is required, any restrictions, emergency shut down procedure and the period the permit covers. The equipment must indicate that it has a permit to operate out-of-hours and the permit must be available within the laboratory, preferably in the safety folder. 10. ASSESSOR AND AUTHORISATION An assessor will complete and sign the Risk Assessment and any associated safety assessments (e.g. COSHH), the assessor must also get authorisation from their supervisor or his nominee (competent person). By signing the safety assessment the Supervisor takes on the responsibility that what has been written on the safety assessment is true and that the control measures identified make the task as safe as reasonably possible. The Safety assessment MUST then be seen by a safety advisor or his nominee who will give it a unique reference number and forward a copy to the School Senior Safety Advisor for recording into the database. Some assessments need to be also seen by other people, this could be due to local rules, the nature of the task, etc. ivan.easdon@manchester.ac.uk (School Senior Safety Advisor) room C15, Materials Science Building, Ext. 63596 3 SOM007 11. THE ASSESSMENT Copies of the assessment must be kept: In a Safety Folder (located near to the entrance to the laboratory) Reference to the relevant safety assessments to be displayed near to the task By School Safety Advisor By Unit Safety Advisor By Assessor 12. RE-ASSESSMENT Risk Assessment and associated safety assessments must be re-assessed if: Any change in legislation or guidelines – e.g. change in the regulations Any change to the assessed task – e.g. to operate 100°C higher Any change in “who might be harmed” – e.g. change in class of user Any change in location of task – e.g. move task to smaller room Any modifications to task – e.g. new limit switches attached Any other factor that may affect the risks of the task – e.g. new machine restricts access One year since last assessment 13. REVIEW A risk assessment review is where a supervisor or competent person re-authorises a risk assessment. A risk assessment must be reviewed when: The annual renewal date is reached and the risk assessment is still suitable and sufficient, i.e. it identifies all the potential hazards, harm and control measures to prevent harm. A small change to the existing risk assessment is required, i.e. where there is no increased risk. When a risk assessment is reviewed a copy of the new risk assessment must be sent to the Safety Advisor to record the review and any changes. ivan.easdon@manchester.ac.uk (School Senior Safety Advisor) room C15, Materials Science Building, Ext. 63596 4 SOM007 SCHOOL OF MATERIALS RISK ASSESSMENT FORM Numbers in square brackets, [1], indicate the relevant section ivan.easdon@manchester.ac.uk (School Senior Safety Advisor) room C15, Materials Science Building, Ext. 63596 5 SOM007 APPENDIX A: Handling Movement HAZARDS Hazard Sharp, heavy, slippery, abrasive, lifting, awkward, unbalanced, unstable, large, minute, repetitive Falls: working at height, use of ladders, use of steps, climbing up or down, guard Possible injury / effect Cuts and abrasions, strains, sprains, crushing injuries (contusions) Fracture, sprains, bruises, cuts and abrasions rails at height, fall from height. Trips: irregular floors, worn or lifting floor covering, trailing cables, debris, obstruction. Slips: liquid on floor, oil or grease, ice, rubbish, footwear. Mechanical Tools, machinery, cutting equipment (knives, guillotines, glass, sharps), flying debris, rotating parts, crushing, rotating, sliding, falling, entrapment, vibrating tools. Pressure / Vacuum Gas cylinders, pressure vessels, steam generators, pipe work, exhaust, implosion or Heat Hot surfaces (contact and radiation), hot liquids, heaters, fires, cold surfaces, cold Cuts and abrasions, crushing injuries - contusions, puncture wound, hand, arm vibration syndrome Blast injuries, Cuts and abrasions, contusions explosion, relief valves. Burns, scolds liquids. Fire Electrical Radiation Combustible and flammable substances (solid, liquid or gas), means of escape, extinguishers, detectors (smoke, fire, oxygen, gas). High voltages/ current AC or DC, frequency, mains electricity, faulty wiring / equipment, electrical testing, heat, spark. Burns, scolds, asphyxiation, Ionising (X-Ray, beta, gamma) and non Ionising (laser, infra-red, ultra-violet, Burns, radiation injury Electrocution, burns, death, fire microwaves, welding), interlocks, systems of work. Substances Chemicals, cleaning materials, dusts, asbestos, biological materials, absorption, spills, reactions, explosions, burns, irritant, toxic. Burns, poisoning, sensitisation, mutagenic, tetragenic, cancer, infection Noise Machinery, pressurised gas vents. Hearing damage, vibration damage Visual Computers, VDU’s, monitors. Strains, muscoskeletal discomfort Water / floods Electrical, slipping. Electrocution, slips, fracture, sprains, strains, contusions Work environment Personal Lone working, out-of-hours working Illness, injury Latex / non-latex gloves Sensitisation ivan.easdon@manchester.ac.uk (School Senior Safety Advisor) room C15, Materials Science Building, Ext. 63596 6