Safe Operating Procedures for Grinders Purpose To define the safe

advertisement

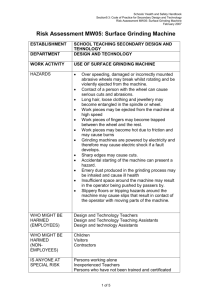

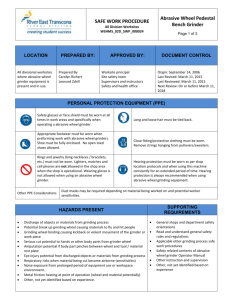

Safe Operating Procedures for Grinders Purpose To define the safe operating procedures in a manner that informs and instructs employees of [Employer/Organization Name] on the key health and safety hazards and controls to remember when using the grinder. Hazards The following hazards may occur when using the grinder: Eye injury Burns Pinching injury Musculoskeletal disorder Dust and particulate Fire Grinding wheel may shatter Personal Protective Equipment Safety footwear Eye protection (e.g. safety goggles with high impact lenses to protect eyes and face shield) Hearing protection Respiratory protection as required Appropriate clothing (e.g. long sleeves and apron) No loose clothing, hair or jewelry Safe Operating Procedure Complete a pre-use inspection. If any defects are noted, the equipment must be removed from service and the supervisor must be notified immediately to ensure equipment is repaired. Operators must have read and understood the operator’s manual. Ensure operator’s manual for equipment is available to operators. Ensure guards and shields are firmly in place and in good condition. Do not operate the equipment without appropriate guards, shields, plates and other safety protective devices in place. Ensure safety decals are legible, order replacements if they are not. Ensure the equipment is used properly as per manufacturer’s directions. Ensure plastic shield protectors are in good condition and adjusted properly. Never operate a grinder without the proper guard in place. Keep floors free of obstructions to prevent slips and trips in the grinding area. Ensure that plugs and cords do not have loose or bare wires. Remove any flammable or combustible materials from the area. Always disconnect the grinding tool from its power source before installing or changing wheels or discs. When mounting a grinding wheel, follow the manufacturer’s recommendations. Ensure that grinding tools are marked for maximum speed. Never use an unmarked tool. Do not use wheels designed for steel on porous materials such as wood, plastic or aluminum. Ensure that the wheels are not damaged in any way (e.g. chipped or cracked). Dispose of damaged wheels immediately. Never use a wheel that has been dropped. Store grinding wheels in an area away from extreme heat or cold and away from impact damage. Apply lockout and tagout procedures to any damaged equipment immediately. Report any grinder, grinding wheel or grinding wheel guard that appears to be defective to the supervisor immediately. Before turning on the power, make sure the wheel runs true and unobstructed. Stand to the side of the grinder when first turning on the power. Ensure adequate ventilation with a hood or appropriate ventilation system to control dust exposure to employees. Operate the wheel at a speed which does not exceed the manufacturer’s maximum operating speed recommendations. Ensure that the wheel speed is equal to or greater than the grinder’s maximum speed. Bring the work piece slowly and smoothly into contact with the wheel. Never use rags to protect your hands or to hold material while grinding. Never allow work to get above the centre line of the grindstone where it could be snapped out of your hand. Measure speed on grinders regularly and following any maintenance or repair work done to the equipment. Dispose of damaged wheels immediately. Clean and service grinders according to manufacturer’s instructions. Keep a record of all maintenance. Repairs to the equipment must be performed by qualified personnel, using original equipment manufacturer (OEM) parts or equivalent. Portable Grinders Ensure that equipment will not operate when unattended by checking the dead-man (constant pressure) switch. Ensure that the grinder does not vibrate or operate roughly. Store portable grinders on racks or hooks. Mounting flange surfaces must be clean and flat. Use the mounting blotters supplied. Run newly mounted wheels at operating speed for one minute before grinding. Do not clamp portable grinders in a vise for grinding hand-held work. Do not use any liquid coolants with portable grinders. Do not force wheels onto a grinder or change mounting hole sizes. Do not tighten the mounting nut excessively. Measure the speed of governor-controlled, air-driven grinders after 20 hours of use or every week, whichever comes first. Measure the speed after any repairs. Measure the speed of electrically driven grinders monthly and after repairs. Ensure portable grinder has a protective cover at least 120 degrees of the circumference of the wheel. Bench Grinders Fasten the bench grinder securely. Do not side grind on the flat side of a straight wheel; use wheels designed for this purpose. Do not adjust the work rest while the wheel is moving. Use a work rest to support and guide the tool and use a tool holder if one is available. Ensure that the work rest for the grinding wheel has a maximum clearance of three milimetres (0.125 inches) from the grinding wheel. Ensure that the work rest is in a position above the centre line of the grinding wheel. Maintain six milimetres (0.25 inches) wheel exposure with a tongue guard or a movable guard. Only grind material that the wheel was intended to grind. Dress wheels regularly. Replace any wheel that cannot be dressed. Document Management Effective Date: Revision Date: