Proposal for NSF 426 Criterion 5.3.1

advertisement

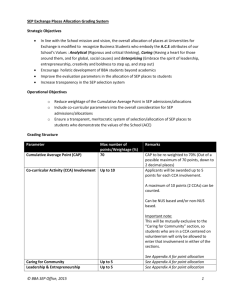

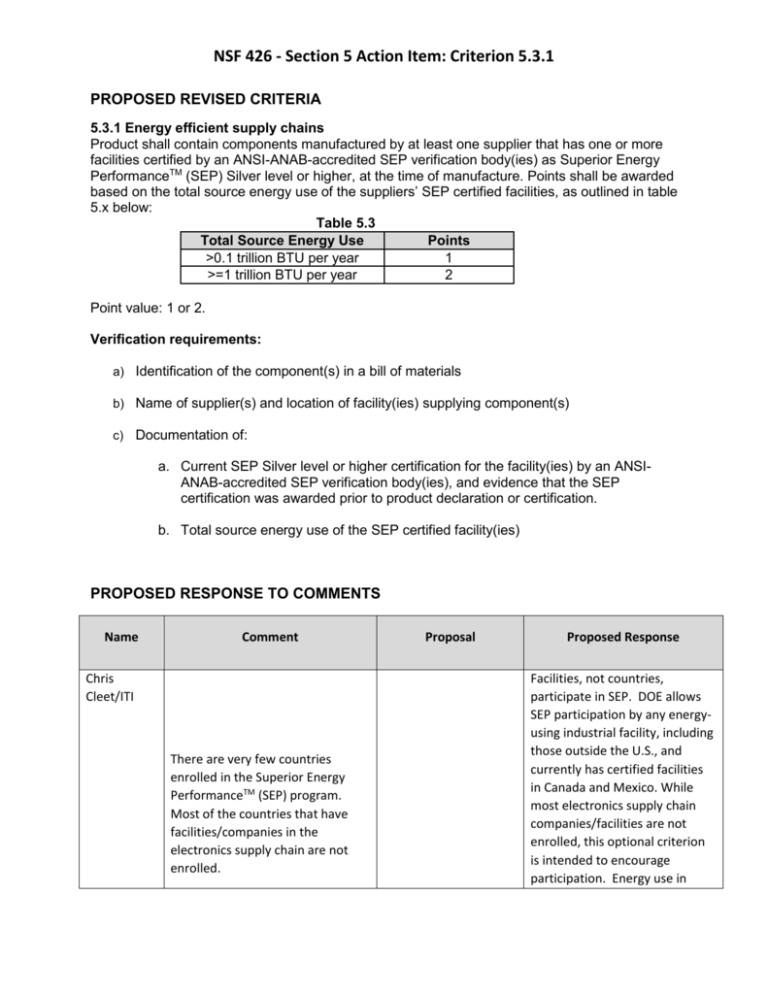

NSF 426 - Section 5 Action Item: Criterion 5.3.1 PROPOSED REVISED CRITERIA 5.3.1 Energy efficient supply chains Product shall contain components manufactured by at least one supplier that has one or more facilities certified by an ANSI-ANAB-accredited SEP verification body(ies) as Superior Energy PerformanceTM (SEP) Silver level or higher, at the time of manufacture. Points shall be awarded based on the total source energy use of the suppliers’ SEP certified facilities, as outlined in table 5.x below: Table 5.3 Total Source Energy Use Points >0.1 trillion BTU per year 1 >=1 trillion BTU per year 2 Point value: 1 or 2. Verification requirements: a) Identification of the component(s) in a bill of materials b) Name of supplier(s) and location of facility(ies) supplying component(s) c) Documentation of: a. Current SEP Silver level or higher certification for the facility(ies) by an ANSIANAB-accredited SEP verification body(ies), and evidence that the SEP certification was awarded prior to product declaration or certification. b. Total source energy use of the SEP certified facility(ies) PROPOSED RESPONSE TO COMMENTS Name Comment Chris Cleet/ITI There are very few countries enrolled in the Superior Energy PerformanceTM (SEP) program. Most of the countries that have facilities/companies in the electronics supply chain are not enrolled. Proposal Proposed Response Facilities, not countries, participate in SEP. DOE allows SEP participation by any energyusing industrial facility, including those outside the U.S., and currently has certified facilities in Canada and Mexico. While most electronics supply chain companies/facilities are not enrolled, this optional criterion is intended to encourage participation. Energy use in NSF 426 - Section 5 Action Item: Criterion 5.3.1 supply chain manufacturing is repeatedly noted as a significant impact across the electronics lifecycle and this criterion is intended to provide recognition to manufacturers attempting to mitigate this impact through a recognized and successful program. Tim Mann/IBM We do not support this criterion. It provides little or no indication of the energy efficiency of the supply chain. Servers have thousands of components. Giving credit for having one supplier facility certified to SEP out of the total supply chain provides no effective differentiation of server products. Currently, there are a limited number of suppliers of server components on the SEP certified facility list. The cost of the certification, when coupled with the cost of attaining ISO 14001 and 50001 certifications will be prohibitive for many companies. http://www.energy.gov/eere/amo/ certified-facilities The criterion has been revised to ensure that recognition is only provided for use of an aggregate of suppliers that represent significant energy savings, and has been revised to allow recognition for participation of any part of the supply chain. The energy savings data does not need to be collected by the manufacturer, as it is kept on file with SEP. Analysis of SEP certified facilities notes a marginal cost for SEP certification above and beyond 50001 certification, but with a significant payback. While most electronics supply chain companies/facilities are not enrolled, this optional criterion is intended to encourage participation. Energy use in supply chain manufacturing is repeatedly noted as a significant impact across the electronics lifecycle and this criterion is intended to provide recognition to manufacturers attempting to mitigate this impact through a recognized and successful program.