Functional Specifications

advertisement

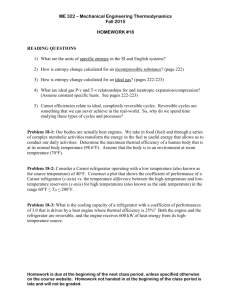

University of Portland School of Engineering 5000 N. Willamette Blvd. Portland, OR 97203-5798 Phone 503 943 7314 Fax 503 943 7316 Functional Specifications Team STEEL Bridge: A Digital Thermostat Contributors: Shawn Patterson Chris Wong Kyle Woodard Approvals Name √ Date Dr. Albright Name Date Dr. Nuxoll Insert checkmark (√) next to name when approved. UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATIONS REV. 0.95 TEAM STEEL BRIDGE PAGE II Revision History Rev. Date Author Reason for Changes 0.5 0.8 0.85 0.86 09/13/03 09/14/08 9/21/08 9/23/08 9/24/08 K. Woodard K. Woodard K. Woodard K. Woodard C. Wong 0.87 0.88 9/24/08 9/25/08 K. Woodard S. Patterson 0.9 0.92 0.95 1.0 9/25/08 10/2/08 10/6/08 10/30/2008 All K. Woodard K. Woodard K. Woodard Wrote Background/Introduction Wrote Requirements Section Formatted Styles Updated Background Formatted Design, Development, Conclusions, Appendices Wrote Preliminary Design Updated Milestones, Assumptions and edited Intro, Background Finished Functional Spec Revised Func Spec Revised Func Spec Made Industry Rep’s Changes UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG . REV. 1.0 PAGE III . TEAM STEEL BRIDGE . . . . . Summary....................................................................................................................... 1 . . FUNCTIONAL SPECIFICATIONS Table of Contents Introduction .................................................................................................................. 2 Background .................................................................................................................. 3 Requirements ............................................................................................................... 4 Overview ..................................................................................................................................................4 Physical Specifications............................................................................................................................5 Size ...................................................................................................................................................5 Display ..............................................................................................................................................5 Graphical User Interface ..................................................................................................................5 Environmental Specifications .................................................................................................................6 General .............................................................................................................................................6 Temperature .....................................................................................................................................6 Shock and Vibration .........................................................................................................................6 Hardware Specifications .........................................................................................................................6 System Hardware ............................................................................................................................6 Power Supply ............................................................................................................................7 Thermocouple ...........................................................................................................................7 Graphical User Interface ...........................................................................................................7 Display .......................................................................................................................................7 Buffers........................................................................................................................................7 Relay..........................................................................................................................................7 Amplifier .....................................................................................................................................7 Board Hardware ...............................................................................................................................8 MOSIS .......................................................................................................................................8 Software Specifications ...........................................................................................................................8 UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG . REV. 1.0 PAGE IV . TEAM STEEL BRIDGE . . B2Logic . ..............................................................................................................................................8 . Preliminary. Design ...................................................................................................... 9 . Overview.of System Architecture ...........................................................................................................9 FUNCTIONAL SPECIFICATIONS Component Details............................................................................................................................... 10 Thermostat Controller ................................................................................................................... 10 Relay System ................................................................................................................................ 11 LED Display and User Interface ................................................................................................... 12 Use Case .............................................................................................................................................. 12 User Sets Thermostat ................................................................................................................... 12 Development Process ...............................................................................................13 General Approach ................................................................................................................................ 13 Assumptions ......................................................................................................................................... 14 Milestones ............................................................................................................................................. 14 Risks ..................................................................................................................................................... 16 Faulty MOSIS Chip Fabrication.................................................................................................... 17 Analog-to-Digital Converter Malfunctions .................................................................................... 17 AFROTC Member’s Time Commitment Could Hinder Our Progress: ....................................... 17 Failing to Finish MOSIS Design by November 26, 2008: ........................................................... 17 Resources............................................................................................................................................. 18 Personnel....................................................................................................................................... 18 Preliminary Budget ........................................................................................................................ 18 Equipment ..................................................................................................................................... 18 Facilities ......................................................................................................................................... 19 Conclusions ...............................................................................................................20 Appendices.................................................................................................................21 Appendix A: 7-Segment Display.......................................................................................................... 21 UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG . REV. 1.0 PAGE V . TEAM STEEL BRIDGE . . Appendix .B: Up/Down Counter ........................................................................................................... 22 . . . . FUNCTIONAL SPECIFICATIONS UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG . REV. 1.0 PAGE VI . TEAM STEEL BRIDGE . . . . . Figure 1. Block Diagram of Team STEEL Product.......................................................................................4 . . Figure 2. Team STEEL System Architecture................................................................................................9 FUNCTIONAL SPECIFICATIONS List of Figures Figure 3. Block Diagram of Thermostat Controller (MOSIS Chip)............................................................ 10 Figure 4. Block Diagram of Relay System ................................................................................................. 11 Figure 5. Front View of LED Display and User Interface .......................................................................... 12 Figure 6. Seven Segment Decoder ............................................................................................................ 21 UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG . REV. 1.0 PAGE VII . TEAM STEEL BRIDGE . . . . . Table 1. Physical Specifications ....................................................................................................................5 . . Table 2. Environmental Specifications ..........................................................................................................6 FUNCTIONAL SPECIFICATIONS List of Tables Table 3. System Hardware Specifications ....................................................................................................6 Table 4. Board Hardware Specifications.......................................................................................................8 Table 5. Software Specifications ...................................................................................................................8 Table 6. Responsibilities and Time Management ..................................................................................... 13 Table 7. Team STEEL Milestones ............................................................................................................. 14 Table 8. Team STEEL's Risks.................................................................................................................... 16 Table 9. Team STEEL's Budget ................................................................................................................. 18 Table 10. Truth Table for LED Display ....................................................................................................... 21 Table 11. Next State Logic.......................................................................................................................... 22 UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION Chapter REV. 1.0 TEAM STEEL BRIDGE PAGE 1 Summary 1 Team STEEL Bridge has designed a digital thermostat that will be installed in a refrigerator. Our functional specifications document outlines the critical steps that went into the planning of our project. Brainstorming all aspects of the project has benefitted our team in numerous ways. A thorough design will minimize future headaches because we are able to predict future problems. Considering all of the steps that will go into the final product, decisions can be made now that will simplify our final product. After the introduction and background, this document allowed us to predict all of the physical requirements that would affect the design of our project. The requirements section requires us to brainstorm physical, environmental, hardware and software requirements. Thinking from a user’s perspective, we can address design problems before they exist. The preliminary design section is complete with block diagrams that specifically outline the different sections of the digital thermostat. Broken into the following segments, the reader can better understand the design of the project. These different segments consist of the relay, user interface and display, and the thermostat controller. Connecting the thermostat controller to the refrigerator’s compressor is a relay. The relay acts as a switch. The user interface is simply up/down buttons that set the thermostat and the seven segment display is mounted next to the user interface on top of the refrigerator. Next is the design process, which outlines many important parts of our project. They include assumptions, milestones, risks and resources. All of these are tools to aid in the design of our project similar to the requirements section. The resource section ensures that our design is within our budget. Risks are important to analyze as well because it is another tool to predict problems that a user might face. If a risk is substantial, then we can make design adjustments accordingly. The same applies to the assumptions section as well. Milestones are used specifically for time management purposes and help keep us on track. Lastly, our document is ended with conclusion and appendices sections. The conclusion addresses how our project plays into the importance of our college education because we are able to pull all of our skills together to create a substantial project. The appendices sections outlines equations, truth tables and other data that is important to understanding our project. UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION Chapter REV. 1.0 TEAM STEEL BRIDGE PAGE 2 Introduction 2 The functional specification is aimed towards industrial representatives, University of Portland faculty and fellow students wishing to obtain a thorough understanding of the project created by Team STEEL Bridge. The goal of the senior capstone design project is to apply our engineering education in a controlled, guided environment. This document provides in detail how Team STEEL Bridge will accomplish its goals. If students wish to expand our project in the future, they may use this document as a guideline and gain valuable knowledge about how to avoid any errors that we encountered in the design and test phases. However, just as valuable as this document will be to those reading it, it is even more valuable to our team as we create it. There are many tasks to accomplish to properly piece together the entire document. These tasks include brainstorming specific requirements and obstacles that may be faced in the construction of our project. For example, physical and environmental specifications will be explained in great detail, as well as hardware and software requirements. By explaining these specifications through this document, we are forced to limit the scope of our design. This is important because an understanding of this scope forces the details of many aspects of our design. Also, in the development process we are specifically required to outline plausible risks. A description of the risk allows us to understand why it is important to avoid it, and can help us prevent it from actually happening.. In addition, we can determine the severity of the risk and create contingencies that we will take if the risk were to occur. These risks could spark ideas and raise caution about our design that may force us to change our plans. Identifying these problems benefits our team by allowing us to improve the testing phase. By identifying possible obstacles, we can devise tests that will improve our chance of success in senior design. Another benefit to the functional specification is that we have to plan our overall progress for our design in advance, which will directly improve our time-management skills. We are able to identify all of the tasks necessary to finish the project and monitor our progress closely. As we continue to work on the project we can manage our time by setting goals, specifically to plan on finishing different tasks by certain dates. By identifying the specific tasks we can be more productive by focusing our efforts on accomplishing them one at a time. This is opposed to spending time on multiple tasks and making minimal progress. A budget is also included to aid in our organization. Our design and overall scope of the project is guided by the restrictions placed on our budget. Thus we are required to brainstorm all costs and resources we must utilize in the completion of our project. All aspects of our project are discussed in the functional specifications document except for the progress that was made in finally deciding on a project. Our original idea went through many changes before we settled on the refrigerator and this preliminary stage is not included in this document. This document does, however, cover almost all aspects of the project from its conception forward. Specifically, this document includes an introduction with a summary and background; physical, environmental, hardware and software requirements; preliminary design stages; development process including risks, assumptions and the budget; conclusion and all necessary appendices. UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION Chapter REV. 1.0 TEAM STEEL BRIDGE PAGE 3 Background 3 The motivation for our project was the fact that modern refrigeration systems lack accurate temperature control. Modern refrigerators are built with a turn dial setting for temperature, where the range is an abstract “1-10” value. It is unclear what these values correspond to in terms of actual temperature inside the refrigerator. Without such knowledge it is impossible to know if our food is being kept at its optimal cooling temperature. Our number one goal with this project is to deliver precise temperature measurements from a refrigeration system to the user and even allow the user to select the exact temperature they want their food at. We want to accomplish this goal by digitally displaying the temperature of the contents of our refrigerator and creating a user interface where anyone can digitally set their desired temperature. Common refrigerators cannot set and gauge a specific temperature, but have a certain range where the temperature can dwell in. Our goal is to improve the design of an average refrigerator by reading and displaying an accurate reading, and being able to set a desired temperature, which the system will never exceed. Our project is centered on MOSIS technology. MOSIS is an industrially manufactured integrated circuit that allows us to put all digital logic onto a high density programmable chip. This programmable chip will house all of the low-level thermostat related digital processing. Also, the chip will have user friendly in/out (I/O) features. These include allowing a user to see the current temperature inside the refrigerator through several 7segment LED displays and letting a user set a desired temperature through the use of up/down arrows corresponding to 1º F per push. Also, the chip will be able to electronically drive a relay when needed, which will activate the refrigeration system. All outputs from the MOSIS will be buffered and run through amplifiers in order to drive to the loads that are attached to it. Other technology that is used is a common seven segment display that is similar to one that found on most digital clocks, a digital solid-state relay that runs the refrigerator’s compressor, a user interface, a temperature probe that outputs a voltage corresponding to the refrigerator’s temperature and an analog-to-digital converter to input that voltage into the MOSIS. Our project will be extremely marketable to anyone who would like to keep their food at its optimal temperature. A thermostat is a simple concept accepted by all consumers because they are all familiar with its workings. The user interface is simple and the digital displays are convenient to read as well. The concept of a refrigerator is simple. Team STEEL is simply enhancing its features. UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE Chapter PAGE 4 Requirements 4 Team STEEL is constructing a digital thermostat that will be installed into an existing refrigerator that will be subjected to various physical requirements, but only a few will hinder our design. The size of our refrigerator is large enough to not limit any of our design specifications, except for the fact that most of the components must be inside of the refrigerator. Near the compressor there is little room to mount our hardware and inside the refrigerator our display and temperature sensor must not conflict with the refrigerator’s functionality. Hardware requirements will arise because the MOSIS will require buffers on all of the outputs. Specifically, the MOSIS technology will rely on other components to drive the different functions of the refrigerator. The software that writes to the MOSIS is restricted and requires certain programming techniques to accommodate for the limited library. Overview Team STEEL is aiming to solve the persistent problem of consuming foods and beverages that are not stored at a constant specified temperature. From outside the refrigerator, consumers will be able to set a desired temperature and the correct temperature will be displayed digitally as well; illustrated by the block diagram in figure 1. Temperature Sensing Device User Input/ Temp Display MOSIS Thermostat Controller Refrigerator Cooling System Figure 1. Block Diagram of Team STEEL Product Our system is centered on the MOSIS chip, located in the center of the diagram. This chip houses all thermostat logic. The thermocouple module is a box designed to take in the voltage from a thermocouple probe which will be located on the inside of our refrigerator. The thermocouple probe is the connection of two different metals at one point which UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 5 generates a voltage proportional to temperature. The thermocouple module will take in this voltage, reference it to 0º F and convert it to a reading in milli-volts that corresponds directly to the temperature. This voltage is then sent to an Analog-to-Digital Converter (ADC) where it will be represented by a six-bit word. Once the MOSIS chip sees this data it compares this temperature with the desired temperature set by the user. If the desired temperature is less than the sensed temperature, the MOSIS sends a voltage to an output connected to the refrigerator’s compressor. However, the MOSIS chip does not have the driving capability for the compressor, so the output is run into a buffer which drives an amplification stage before finally driving the compressor. Physical Specifications Table 1. Physical Specifications Requirement Value Size Display Graphical User Interface Limited Visible Accessible Size The size of the refrigerator is already set because our project is centered on enhancing an existing refrigerator. The size of our project comes within mounting our hardware inside the compartment next to the compressor. Our product needs to be able to fit in a refrigerator without causing spacing issues with its surroundings. The MOSIS chip and its housing, the relay, current driving amplifier and thermocouple module are small enough that we should not have any problems. Display Displaying the correct temperature must be done so that a consumer can read the temperature from a fair distance in the home. This is why we did not use LCD, the LED lights will display with ample brightness. They will also be displayed on top of the refrigerator, vertically and on the front edge so that a consumer of any height can easily view it. Graphical User Interface The buttons to set the temperature will be located next to the LED display. This will be more convenient for our team because it will limit the amount of wire along the outside of the refrigerator. Consumers will be able to reach the buttons because it will be on the front of the refrigerator. UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 6 Environmental Specifications Table 2. Environmental Specifications Requirement Value Temperature Shock and Vibration 0°- 63° Minimal General The refrigerator will only be subjected to use inside of the home. We will discourage any consumer from using the product outside. Temperature All of our hardware will be protected from extreme cold or hot temperatures in the bottom backside of the refrigerator. The only hardware that will be inside of the actual refrigerator will be the temperature probe from the thermocouple. The temperature probe is a steel wire that can withstand extreme temperatures that cannot be replicated in the environments encountered by our project. The probe will only endure a temperature between 0° and 63° Fahrenheit given our assumptions and having only six bits to work with. Shock and Vibration Once the compressor turns on, there might be a little vibration that could disrupt the MOSIS or relay after a long period of use. The vibration is subtle, so it will take a little planning and repeated testing to ensure that our hardware can withstand the shock and vibration. Hardware Specifications System Hardware Table 3. System Hardware Specifications Requirement Value Power Supply Thermocouple 5 VDC 0-63 mVDC TBD* TBD Buffers Amplifier UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE Relay Display Graphical User Iinterface PAGE 7 TBD TBD TBD *To Be Determined Power Supply A power supply will tie into the power supplied into the compressor, which is supplied by 110 V. Regulating this voltage is yet to be determined so that we do not burn up the MOSIS, but he MOSIS does requires a 5 volt DC input. and this will be regulated from the power supply. The thermocouple requires a 9 volt battery to operate. Thermocouple Temperature will be sensed with a thermocouple that will be located with the rest of the external hardware next to the compressor. It measures temperature by comparing a difference from the temperature probe to a saved reference temperature. The output is a voltage that is measured in milli-volts. Graphical User Interface Users will be able to directly set the desired temperature with two buttons that are designated up or down. Each push will correspond to a one degree change. The set temperature will be displayed on two 7-segment displays. Display Several seven segment LED arrays will be used to visually display the present and desired temperatures. Buffers All outputs of the MOSIS will be sent to buffers that will prevent damage caused by current entering the outputs. Plus, they will help drive the external components. Relay A solid-state transistor will be used to turn the compressor on and off. This will replace the physical relay made up of two metal contacts that are controlled by a current created through a coil to close the contacts. This allows the MOSIS to digitally control the compressor and replace an electro-mechanical device which has less resilience to repeated use. Amplifier The MOSIS chip does not have enough power on its own to drive the compressor, so amplification is required prior to the compressor. This stage may require multiple stages until the required amplification is reached. We will not know how much amplification is required until we get our test refrigerator and determine its current draw. Once the current UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 8 draw is determined, we will work backwards to find out how many amplification stages are required. Board Hardware Table 4. Board Hardware Specifications Requirement Value MOSIS TBD MOSIS The convenience of using a MOSIS chip is that all logic is centered in one device. All inputs from the graphical user interface (GUI) and thermocouple and outputs to the compressor and display are tied straight to the MOSIS. Software Specifications Software Specifications contains a list of the software that will be required to run or support the system. Table 5. Software Specifications Requirement Value B2Logic.blt L-edit ABEL TBD TBD TBD B2Logic B2Logic is the software that will be used to write our logic. This data can then be converted to write our Complex Programmable Logic Device (CPLD) or MOSIS chip. L-Edit L-edit is a layout editing software used to get the .edf files from the B2Logic in order for the MOSIS chip to be fabricated. ABEL Advanced Boolean Expression Language (ABEL) is a hardware description language used to burn digital logic information onto a CPLD. It will be our backup circuit should our MOSIS chip not function. UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION Chapter 5 REV. 1.0 TEAM STEEL BRIDGE PAGE 9 Preliminary Design Overview of System Architecture Thermocouple Module User Input/ LED Display Buffer 6-bit Analog/Digital Converter MOSIS Chip (Thermostat Controller) Buffer Solid-State Relay Compressor Figure 2. Team STEEL System Architecture UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 10 The basic principles of our project are displayed in Figure 2. The thermocouple module is a temperature probe and inputs temperature into the MOSIS. After reading the temperature of the refrigerator from the display the user adjusts the temperature accordingly with the buttons mounted next to the display. Using both of these inputs, the MOSIS decides if the compressor needs to be activated. The component details’ section outlines the specifics on how all of the functions are executed. Component Details Thermostat Controller 6-bits from A/D Holding Register #1 To LED Display Clock Average Holding Register #2 Set Temp From User Input (6-bits) Comparator Output pin to Compressor (On if Set<Average) Figure 3. Block Diagram of Thermostat Controller (MOSIS Chip) The thermostat controller has two inputs. The first is from the ADC converter that receives its input from the thermocouple. Temperature is read from the thermocouple and outputs a voltage into the ADC converter. Voltage is then converted into a six bit binary number that inputs into the first holding register in the MOSIS. Connected into the comparator is UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 11 the temperature thermostat set directly from the user interface which consists of two buttons, representing up and down arrows. From the ADC converter the six bit binary number goes into the first holding register. At the next rising edge of the clock, the binary number goes into the second register and the first register acquires another reading from the ADC converter. Next, the two register values are placed into the averaging segment, where they two binary numbers are added and then shifted to the right in another register to signify dividing by two. Temperature read from the thermocouple module will vary due to a slightly inconsistent temperature inside the refrigerator. In order to avoid having the temperature reading in the 7-segment display from flickering between different readings, Team STEEL has implemented the averaging segment. This average is then sent to the LED display, to display an accurate average reading of the temperature, and to the comparator. Taking inputs from the averaging segment and the GUI, the comparator is then able to determine if the set temperature is less than the actual temperature. If this is the case, a voltage is outputted to the amplifier to turn on the refrigerator’s compressor. Relay System Output from MOSIS Ic Current Amplifier ICOMP Power Transistor ICOM P Load: Compressor of Refrigerator Figure 4. Block Diagram of Relay System If the user’s desired temperature is exceeded, digital information from the MOSIS chip needs to be dispatched to the refrigerator’s solid-state relay system. The solid-state relay turns on the compressor, which in turn, runs the cooling mechanism. The current draw will be determined once we get our refrigerator. Hopefully there will be a nameplate that specifies current draw of the compressor somewhere on the refrigerator. However, if we cannot find a nameplate, we will use a current sensing device to determine the current draw while the compressor is running. To get the current draw to the compressor, current from the output of the MOSIS (IC) is sent through an amplifier, to reach the needed current draw (ICOMP). Then ICOMP goes through a power transistor. The power transistor acts as a switch. The transistor’s switch is open when cooling is not needed. When the desired temperature is exceeded, cooling is needed and the amplified current activates the switch to turn into a short. Then the needed current draw is sent to our load, which is the compressor, and activates the cooling within the refrigerator. UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 12 LED Display and User Interface PRESENT SET UP DOWN Figure 5. Front View of LED Display and User Interface We will group together an LED display and user interface together into a functional block which will sit on top of the refrigerator. The LED display will consist of two sets of two 7segment displays. One set will display the present temperature inside the refrigerator as sensed from the thermocouple module. The other set of 7-segment displays will show what the user has set as his/her desired temperature for the refrigerator. The user interface will consist of two pushbuttons; one for raising the desired temperature one degree and the other for lowering the temperature one degree. Use Case User Sets Thermostat Primary Actor: Average person who wants to keep food from spoiling. Goal in context: Keep food at optimal temperature. Preconditions: The user desires to keep food from spoiling or desires to get a better taste from food that is colder. Trigger: The user notices that food in his/her refrigerator is not cold enough Scenarios: Probe senses temperature sending a corresponding voltage signal to the MOSIS in binary form. MOSIS outputs signal to LED display. User toggles input buttons to a setting cooler than the present temperature. Logic in the MOSIS activates the relay. The compressor turns on and removes heat from the refrigerator. Temperature in the refrigerator is cooler than desired setting and cools food UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 13 Exceptions: User prefers spoiled food. Priority: Essential, must be implemented. When Available: Whenever user wants to walk up and change settings. Frequency of Use: As often as desired. Channel to Primary Actor: Direct physical contact with pushbuttons. Open Issues: None Chapter Development Process 6 General Approach Here is a table depicting Team STEEL’s general approach through our design process. Refer to the key below to see what each team member is working specifically. Table 6. Responsibilities and Time Management Shawn Patterson Chris Wong Kyle Woodard Shawn Patterson Chris Wong Kyle Woodard September 2 1 4,11 1,3 4,11 3 4 February 12 12 12 October 7 1 6 5 March 12 12 12 November 8,9,5 5 8,9,5 9,5 April 13 13 13 December 10,5 10,5 10,5 Key: 1= Design MOSIS Components in B^2Logic 2= Research Thermocouples 3= Research Refrigeration Systems 4= Functional Specifications 5= Theory of Operations 6= Combining MOSIS components and compiling .edf file 7= Get Refrigerator and test current draw 8= Finish Putting Together Full MOSIS design 9= Burn CPLD 10= Mount Hardware UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG January 12,5 12,5 12,5 May FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 14 11= Order Parts 12= Test System, Debug 13= Prepare Presentation and Demonstration for Founder’s Day Team STEEL’s approach to designing our system is to have two people focus on most of the design and have the other person focus on documentation and overseeing the design progress. We begin with doing some basic research about the peripherals surrounding our MOSIS design. Next we need to design the MOSIS, one section at a time before putting it all together in one final product. At the same time, we will collect all other necessary hardware so that we and work with it as soon as the MOSIS design is complete. Also, whenever certain documentation approaches a deadline the whole team works to jointly get it completed on schedule and to make sure everyone is on the same page for the overall design. Since we will have our MOSIS complete before winter break, we will be able to use the entirety of second semester to put together and test our system using a CPLD prior to the MOSIS chip arriving from fabrication. Once the chip arrives, we will be able to insert it into our working system and already be prepare for Founder’s Day. Assumptions This section lists key events that characterize the environment. Here are some assumptions: Consumer only uses temperatures between the ranges of 0-63° Fahrenheit. We are only using 6-bits to represent our temperature in binary. Food in a refrigerator should not go below freezing, or exceed room temperature. The refrigerator is going to use a solid-state relay. Older refrigerators have a different type of relay system which involves a metal strips actuated by current flow. However, newer and more modern refrigerators use a solid-state relay, so we assume our thermostat will be used on the more modern refrigerators. The refrigeration system using our product will be kept in a standard indoor environment. We will not vouch for our product working after getting wet. Nor will we vouch for it working in temperatures required by military standards. Milestones Table 7. Team STEEL Milestones Number Description Original 10 Oct 08 Present 23 Sep 08 1 Pre-Approval Document 29 Aug 08 29 Aug 08 UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 15 2 Order Thermocouple Module 17 Sep 08 17 Sep 08 3 Finish Higher Level Block Diagram 17 Sep 08 17 Sep 08 4 Finish MOSIS Block Diagram 17 Sep 08 17 Sep 08 5 Purchased Refrigerator 20 Sep 08 27 Sep 08 6 Program Review #1 23 Sep 08 23 Sep 08 7 Functional Spec 1.0 10 Oct 08 10 Oct 08 8 Program Review #2 28 Oct 08 28 Oct 08 9 MOSIS Specification Complete 22 Nov 08 22 Nov 08 10 Burn CPLD 23 Nov 08 23 Nov 08 11 Theory of Operations 0.9 24 Nov 08 07 Dec 08 12 Program Review #3 02 Dec 08 02 Dec 08 13 Mount Hardware 03 Dec 08 03 Dec 08 14 TOps version 0.95 23 Jan 09 23 Jan 09 15 TOps version 1.0 30 Jan 09 30 Jan 09 16 Test Thermostat 5 Feb 09 5 Feb 09 17 Debug Thermostat 15 Feb 09 15 Feb 09 18 Put Together Display for Founder’s Day 15 Mar 09 15 Mar 09 19 Presentation and Demonstration for Founder’s Day 07 Apr 09 07 Apr 09 Purchase Refrigerator UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 16 We purchased a test refrigerator in order to figure out the way modern refrigerators work and to test compatibility with MOSIS outputs. Currently, we have a good idea of how a modern refrigerator works to keep the contents cool. However, we have never actually worked with one before. Therefore, we need to be able to experiment with a test refrigerator to get a feel for how the current system works and what we can do to improve it with a MOSIS chip. Also, we need to make sure that we figure out how much current draw is required by a modern refrigeration system. This will determine how much amplification is required after the output of the MOSIS chip. MOSIS Specification Complete It is imperative that we finish the design of our MOSIS chip by this date. On this date, Dr. PeterOsterberg needs to send our finished design off to the MOSIS fabricators so that it will be built and returned to us by the time we need to present our project. Burn CPLD Instead of waiting for our MOSIS chip to return from fabrication, we have the ability to burn our same chip design onto a CPLD. This allows our team to test our design even though our chip still has not come back. Thus, we have more time to test and debug our design. Also, if for some reason the MOSIS comes back ineffective, we already will have a working chip. We want to get the CPLD done as early as possible, which is why the date we set for its burning is the day after required submission of our final design. Getting the CPLD ready early will allow even more time for debugging our design and will aid us in getting ahead of schedule for the second semester. Mount Hardware Mounting all our hardware entails installing all additional devices on our refrigerator. A user display and input will be installed as well as a thermocouple module, CPLD, buffer between our CPLD and cooling system, and a solid-state relay, which drives the cooling system. Just as with the CPLD, we want to get this step done as soon as possible, which for us is early December. This will allow us to begin testing our finished design immediately. As a result, we will be able to finish our testing even before our MOSIS chip arrives. And as soon as the chip does arrive, all we will have to do is install it and we will have a finished product. Risks Table 8. Team STEEL's Risks Risk Severity Likelihood Faulty MOSIS Chip Fabrication Low Low Analog-to-Digital Converter Malfunctions Moderate Moderate UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 17 AFROTC Member’s Time Commitment Could Hinder our Progress Moderate High Failing to Finish MOSIS Design by November 26, 2008: High Low Faulty MOSIS Chip Fabrication Once turning in the final schematics before the November 26th deadline, Dr. Osterberg sends our chip to be fabricated and created. There might be a chance that even if our logic was correct, the fabrication company can mess up our chip, or the chip will not work altogether. If it fails, a CPLD needs to be made before sending the MOSIS chip to fabrication. The CPLD can take the place of a MOSIS. CPLDs hold less digital information, but if there is a lot of data to read, multiple CPLDs can be made to take the place of one MOSIS. Analog-to-Digital Converter Malfunctions The analog-to-digital (ADC) converter is a main component in our project because it sends the information given by the thermocouple digitally to the MOSIS chip. If the converter or our team cannot match the output of the ADC converter to the input of the MOSIS, the project cannot be completed. To avoid troubles with our converter, a lot of research needs to be focused on what ADC converter is the most suitable for our project. Research can be done by looking online or by asking specialists, like our professors or Craig Henry, University of Portland’s electronic technician about which converter to purchase. AFROTC Member’s Time Commitment Could Hinder Our Progress: Kyle Woodard is a cadet in the Air Force ROTC at this university. Having additional responsibilities can slow the process of this project. To remedy this, most of the digital logic (the core of the project) will be left to the other members of Team STEEL Bridge, and Kyle will focus more on the writing and journalistic areas of the project. Time management will be crucial, too. Failing to Finish MOSIS Design by November 26, 2008: All digital logic has to be finished, processed and put into our MOSIS chip design by November 26, 2008. This deadline was put in effect by Dr. Peter Osterberg for all projects that incorporate MOSIS technology. If our group fails to accomplish this, our project will be compromised because it is the core of this project. However, if late, a CPLD can be made to take its place. Due to the simplicity of the MOSIS, it is to our benefit to finish the digital aspect on time. In addition, finishing on time will allow each of us to enjoy our winter break without having to do on our project. UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 18 To avoid this situation, a block diagram of the important sections of the MOSIS will be made immediately. Then each section will be created efficiently on an individual basis. Then after all the parts are designed, each piece will be attached or bussed together as needed. Resources Personnel Below shows who is working on the project and their general or specific role. Christopher Wong. Team leader for Fall Semester. His main role is to configure the digital logic and create the central MOSIS chip. Shawn Patterson. Team leader for Spring Semester. necessary parts and help create the MOSIS chip. Kyle Woodard. His main responsibilities are to uphold and maintain documents and our team’s website. Dr. Robert Albright. He is our primary advisor, and every week he is involved with our group’s team meetings, providing valuable insight and advise. Dr. Peter Osterberg. He is our secondary advisor, and he looks over the well-being of the MOSIS design. He is the specialist in MOSIS technology, and whenever there is a problem with MOSIS, we will turn to him for help. He is also responsible for sending the chip off for fabrication after the internal logic is completely designed. His main role is to order Preliminary Budget Table 9. Team STEEL's Budget Line 1.1 1.2 1.3 1.4 1.5 Category Hardware Hardware Hardware Hardware Materials Description 0.3-Inch, 7-Segment LED Display 80TK Thermocouple Module Analog-to-Digital Converter Current Amplifier Miscellaneous # of Parts 10 1 1 1 1 TOTAL Rate $2.93/10 LEDs $92.24 $3.64 $6.96 $30.00 Amount $2.93 $92.24 $3.64 $6.96 $30.00 $135,77 Equipment Special equipment, or outside equipment that needs to be used is a digital multi-meter (DMM) to test the output voltage of the thermocouple. UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 19 Facilities For testing hardware, we are using laboratory space in Engineering Hall 2001. UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION Chapter REV. 1.0 TEAM STEEL BRIDGE PAGE 20 Conclusions 7 In summary, our team is creating a digital thermostat that will read, set, compare and display the real and user-desired temperatures for a refrigerator, so the consumer can enjoy their cold food and beverages at their liking. MOSIS technology is the core element of this project because all deadlines, digital logic, and completion of this project depend on the completion of this integrated chip. The MOSIS chip will hold all digital logic that will allow us to read the measured temperature, allow the user to set the temperature, compare the set and measured temperatures, and send that information to the refrigerator’s relay system and our to LED temperature display. Because the MOSIS needs to be fabricated, all circuit diagrams and files needed to create this programmable chip need to be done before November 26, 2008 when our secondary advisor, Dr. Peter Osterberg, submits it for fabrication. Forcing our team to compete the MOSIS by an early date motivates, encourages and forces us to have our project, as an entirety, almost complete by Winter Break. Outside MOSIS technology, our team will be using an 80TK Thermocouple by Fluke to sense the temperature inside the refrigerator. That thermocouple will output a voltage, and that voltage will represent a temperature in degrees Fahrenheit, and in turn will be put through an analog-to-digital converter so the number can be represented digitally to our MOSIS chip. Our report shows the steps that is required to make this in great detail, a thorough preliminary design, risks, consumer requirements, and what is necessary both in industry and practice to complete our task. For consumers, this product will be a necessity for cooling foods. For our team, we hope that this project will be another milestone in our quests to becoming efficient and adept electrical engineers. This project will teach us about the industry, teamwork, the extraneous amount of documentation and skills needed to excel once we graduate. Hopefully with the completion of our digital thermostat, we can reach and surpass this goal. UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 21 Appendices Appendix A: 7-Segment Display Figure 6. Seven Segment Decoder Table 10. Truth Table for LED Display Decimal 0 1 2 3 4 5 6 7 8 9 F UNIVERSITY OF PORTLAND 4-Bit Binary ABCD 0000 0001 0010 0011 0100 0101 0110 0111 1000 1001 n/a B0 B1 B2 B3 B4 B5 B6 1 0 1 1 0 1 1 1 1 1 Vs 1 1 1 1 1 0 0 1 1 1 GND 1 1 0 1 1 1 1 1 1 1 GND 1 0 1 1 0 1 1 0 1 1 GND 1 0 1 0 0 0 1 0 1 0 Vs 1 0 0 0 1 1 1 0 1 1 Vs 0 0 1 1 1 1 1 0 1 1 Vs SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG FUNCTIONAL SPECIFICATION REV. 1.0 TEAM STEEL BRIDGE PAGE 22 Appendix B: Up/Down Counter Table 11. Next State Logic Decimal 0 1 2 3 4 5 6 7 8 9 Current State: ABCD 0000 0001 0010 0011 0100 0101 0110 0111 1000 1001 Next State: UP AUBUCUDU 0001 0010 0011 0100 0101 0110 0111 1000 1001 0000 Carryover: Up 0 0 0 0 0 0 0 0 0 1 Next State: DOWN ADBDCDDD 1001 0000 0001 0010 0011 0100 0101 0110 0111 1000 Carryover: Down 1 0 0 0 0 0 0 0 0 0 Truth Table and Next-State Equations for Up/Down Counter with Carryover Bit(s): AU = AB + BCD BU = BC’ + BD’ + B’CD CU = CD’ + A’C’D DU = D’ Carryover UP = AD AD = A’B’C’D’ + AD BD = AD’ + BD + BC CD = CD + BC’D’ + AC’D’ DD = D’ Carryover DOWN = A’B’C’D’ UNIVERSITY OF PORTLAND SCHOOL OF ENGINEERING CONTACT: CHRISTOPHER WONG