Surface analysis by Direct Analysis in Real Time mass spectrometry

advertisement

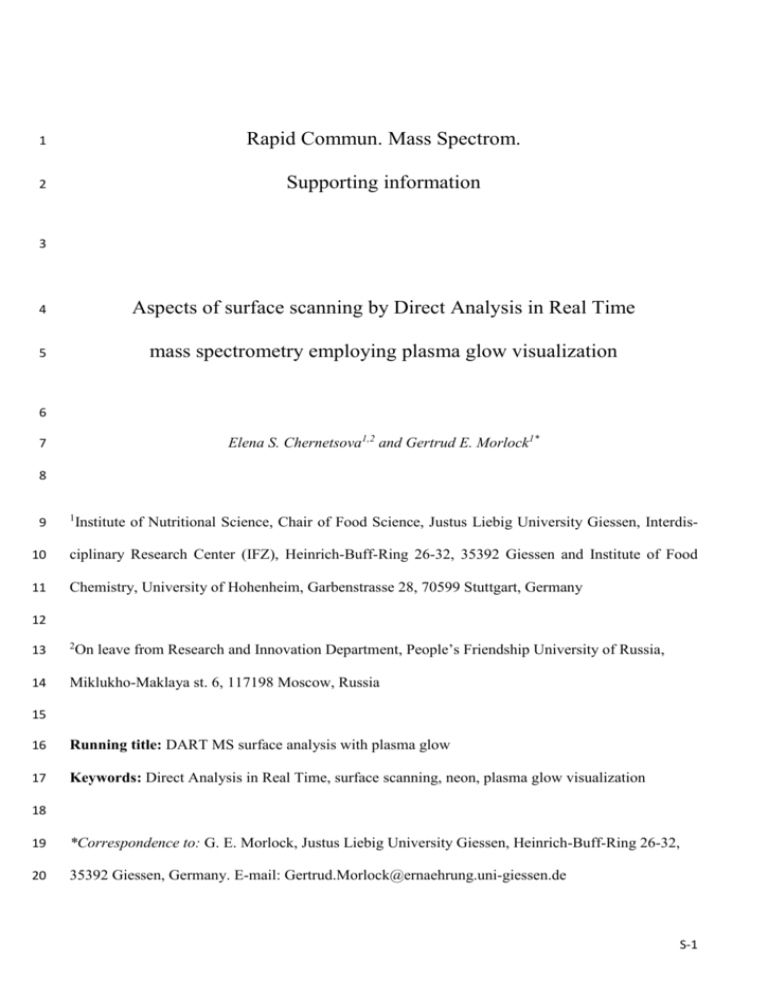

1 Rapid Commun. Mass Spectrom. 2 Supporting information 3 4 Aspects of surface scanning by Direct Analysis in Real Time 5 mass spectrometry employing plasma glow visualization 6 Elena S. Chernetsova1,2 and Gertrud E. Morlock1* 7 8 9 1 Institute of Nutritional Science, Chair of Food Science, Justus Liebig University Giessen, Interdis- 10 ciplinary Research Center (IFZ), Heinrich-Buff-Ring 26-32, 35392 Giessen and Institute of Food 11 Chemistry, University of Hohenheim, Garbenstrasse 28, 70599 Stuttgart, Germany 12 On leave from Research and Innovation Department, People’s Friendship University of Russia, 13 2 14 Miklukho-Maklaya st. 6, 117198 Moscow, Russia 15 16 Running title: DART MS surface analysis with plasma glow 17 Keywords: Direct Analysis in Real Time, surface scanning, neon, plasma glow visualization 18 19 *Correspondence to: G. E. Morlock, Justus Liebig University Giessen, Heinrich-Buff-Ring 26-32, 20 35392 Giessen, Germany. E-mail: Gertrud.Morlock@ernaehrung.uni-giessen.de S-1 21 Table S–1. Influence of the respective vacuum pumping rate on the S/N ratios and their repeatabili- 22 ties (%RSD, n = 5) at characteristic m/z values (as listed in Table 1) Vacuum pumping rate (L min–1) 12 14 16 18 Mean Composition of helium for DART ionization S/N ratios (%RSD, n = 5) p-Coumaric acid Galangin m/z (+) m/z (–) m/z (+) m/z (–) Pure He 14 (23%) 45 (12%) 325 (28%) 166 (6%) He with 10% Ne 20 (104%) 9 (18%) 135 (86%) 72 (18%) Pure He 29 (57%) 22 (23%) 213 (59%) 31 (18%) He with 10% Ne 18 (34%) 4 (18%) 190 (56%) 22 (16%) Pure He 50 (49%) 9 (14%) 257 (33%) 53 (43%) He with 10% Ne 12 (113%) - 131 (37%) 6 (25%) Pure He 6 (76%) 5 (60%) 15 (44%) 26 (41%) He with 10% Ne 22 (65%) - 220 (34%) 4 (8%) Pure He 25 (51%) 20 (27%) 203 (41%) 69 (27%) He with 10% Ne 18 (79%) 7 (18%) 169 (53%) 26 (17%) 23 S-2 24 25 Figure S–1. Surface analysis using the DART SVPA ionization source with xyz-table (3-D scanner). 26 S-3 27 28 Figure S–2. Scanning DART-MS of HPTLC chromatograms of propolis samples and confirmation 29 of the component identity via their ESI mass spectra for selected HPTLC zones[12]. Selected ion mon- 30 itoring (SIM) mode was used for scanning HPTLC-DART-MS in the negative ionization mode 31 (deprotonated molecules of chrysin at m/z 253 [M-H]- and caffeic acid at m/z 179 [M-H]-). 32 S-4 33 34 Figure S–3. Selected coordinates suitable for surface scanning, providing the closest positioning of 35 the standard DART ceramic cap to the analyzed surface. 36 S-5 37 38 39 Figure S–4. Visualization of the gas impact area and heat distribution for exposure times between 4 40 and 20 s and different ion source angles (0–90°) using a heat-sensitive HPTLC plate (horizontal car- 41 rier; gas flow: 3 L min-1; gas heater: 300 °C; cap to plate distance: 5 mm; documentation under UV 42 366 nm (top) and white light illumination (bottom). Reproduced with permission from [14] © 2015 43 John Wiley & Sons, Ltd. 44 S-6 45 46 Figure S–5. Comparison of DART mass spectra obtained for galangin in the positive ionization 47 mode (PI) using 12 and 18 L min–1 as vacuum pumping rates (pure helium as DART gas). S-7 48 49 Figure S–6. Comparison of DART mass spectra obtained for p-coumaric acid in the negative ioniza- 50 tion mode (NI) using 12 and 18 L min–1 as vacuum pumping rates (pure helium as DART gas). S-8 51 52 53 Figure S–7. Comparison of DART mass spectra obtained for galangin in the negative ionization 54 mode (NI) using pure helium or helium with 10 % neon (vacuum pumping rate of 12 L min-1). S-9 55 56 Figure S–8. Simplified DART-MS scheme of gas flow directions in case of surface versus DIP-it 57 analysis. S-10 58 59 60 Figure S–9. Comparison of mass signal intensities in the EIC chronograms of arbutin [M+H]+ ob- 61 tained by scanning DART-MS of arbutin (6 µg applied on a rectangles of 5 x 3 mm2) on an HPTLC 62 plate using the standard (a) and narrow ceramic DART cap (b). S-11 63 64 65 Video S–1 Documentation of the DART glow discharge visualization. S-12