cb173-5.28_tools for lean manufacturing

advertisement

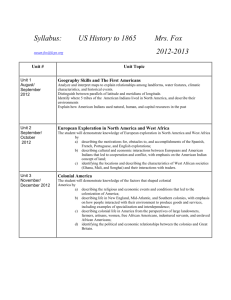

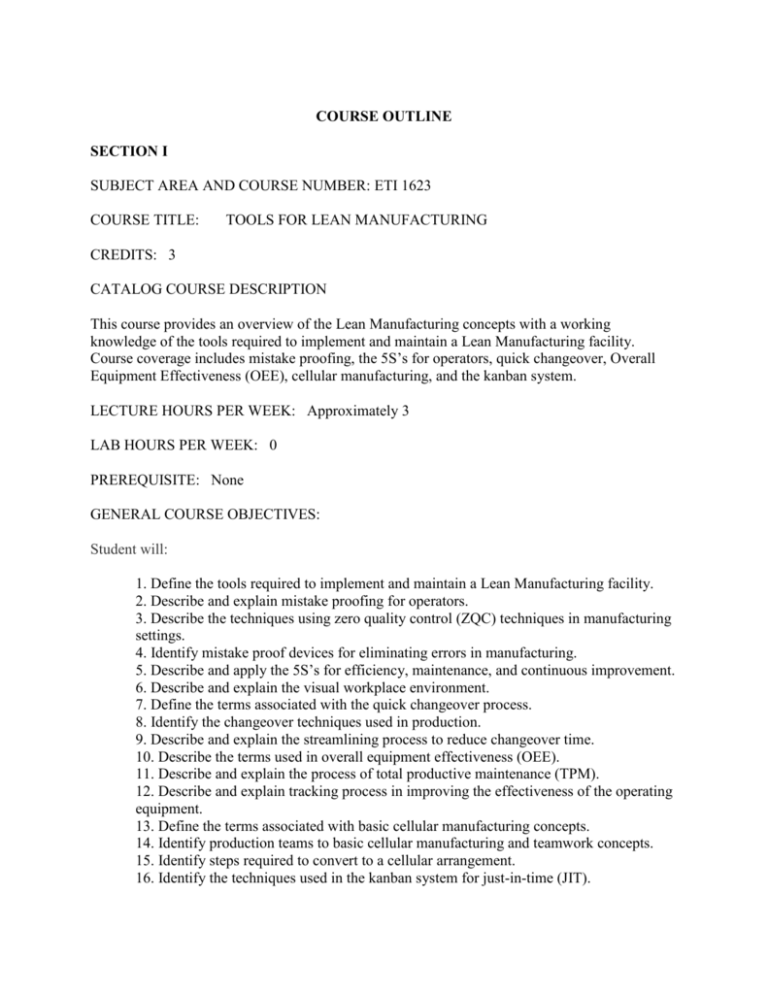

COURSE OUTLINE SECTION I SUBJECT AREA AND COURSE NUMBER: ETI 1623 COURSE TITLE: TOOLS FOR LEAN MANUFACTURING CREDITS: 3 CATALOG COURSE DESCRIPTION This course provides an overview of the Lean Manufacturing concepts with a working knowledge of the tools required to implement and maintain a Lean Manufacturing facility. Course coverage includes mistake proofing, the 5S’s for operators, quick changeover, Overall Equipment Effectiveness (OEE), cellular manufacturing, and the kanban system. LECTURE HOURS PER WEEK: Approximately 3 LAB HOURS PER WEEK: 0 PREREQUISITE: None GENERAL COURSE OBJECTIVES: Student will: 1. Define the tools required to implement and maintain a Lean Manufacturing facility. 2. Describe and explain mistake proofing for operators. 3. Describe the techniques using zero quality control (ZQC) techniques in manufacturing settings. 4. Identify mistake proof devices for eliminating errors in manufacturing. 5. Describe and apply the 5S’s for efficiency, maintenance, and continuous improvement. 6. Describe and explain the visual workplace environment. 7. Define the terms associated with the quick changeover process. 8. Identify the changeover techniques used in production. 9. Describe and explain the streamlining process to reduce changeover time. 10. Describe the terms used in overall equipment effectiveness (OEE). 11. Describe and explain the process of total productive maintenance (TPM). 12. Describe and explain tracking process in improving the effectiveness of the operating equipment. 13. Define the terms associated with basic cellular manufacturing concepts. 14. Identify production teams to basic cellular manufacturing and teamwork concepts. 15. Identify steps required to convert to a cellular arrangement. 16. Identify the techniques used in the kanban system for just-in-time (JIT). SECTION II 1. COURSE CONTENT AND SCOPE: A. OUTLINE OF TOPICS TO BE ADDRESSED IN THE COURSE 1. a. defining the basic principles of mistake proofing. b. describing and using zero quality control (ZQC) techniques in manufacturing settings. c. identifying mistake proof devices in eliminating errors in manufacturing. a. defining the terms used in the 5S’s. b. identifying and describing the steps used in the 5S’s. c. applying the 5S’s for efficiency, maintenance, and continuous improvement. d. describing the visual workplace environment. a. defining the terms associated with the quick changeover process. b. describing the techniques and approaches used in quick changeover. c. identifying the changeover techniques used in production. d. describing the streamlining process to reduce changeover time. e. developing the line changeover approach in manufacturing. a. defining and describing the terms used in overall equipment effectiveness. b. describing the process of total productive maintenance (TPM). c. defining the role of overall equipment effectiveness in eliminating equipment problems. d. describing the three elements of total productive maintenance as used for the output of goods. e. describing the tracking process in improving the effectiveness of the operating equipment. a. describing one-piece flow for work teams. b. defining the terms associated with basic cellular manufacturing concepts. c. describing the cellular manufacturing layouts that promote production flow by cutting waste. d. identifying production teams basic to cellular manufacturing and teamwork concepts. e. describing the steps required to convert to a cellular arrangement. a. describing the just-in-time (JIT) system. b. identifying the techniques used in the kanban system for just-in-time. c. describe ways of improving the productivity process and quality of the product. d. identifying the non-value-adding activities. c. Describing the 10 step implementation plan. 2. 3. 4. 5. 6. B. APPROPRIATE READINGS: None C. WRITING ASSIGNMENTS: None D. APPROPRIATE OUTSIDE ASSIGNMENTS: None E. APPROPRIATE ASSIGNMENTS THAT DEMONSTRATE CRITICAL THINKING: None 2. METHODS OF EVALUATION: Verification of skills by direct observation, exams 3. METHODS OF INSTRUCTION: Lecture Demonstration 4. REQUIRED TEXTS AND SUPPLIES: TBD Syllabus TOOLS FOR LEAN MANUFACTURING (ETI 1623) (Fall 2009) Instructor: TBD Department of Engineer and Process Technology Office: Hrs: Phone: Email: name@lakecitycc.edu Required Textbooks: TBD Additional References: Course Description: This course provides an overview of the Lean Manufacturing concepts with a working knowledge of the tools required to implement and maintain a Lean Manufacturing facility. Course coverage includes mistake proofing, the 5S’s for operators, quick changeover, Overall Equipment Effectiveness (OEE), cellular manufacturing, and the kanban system. Course Content: Course Outcomes: The student will be able to: 1. Define the tools required to implement and maintain a Lean Manufacturing facility. 2. Describe and explain mistake proofing for operators. 3. Describe the techniques using zero quality control (ZQC) techniques in manufacturing settings. 4. Identify mistake proof devices for eliminating errors in manufacturing. 5. Describe and apply the 5S’s for efficiency, maintenance, and continuous improvement. 6. Describe and explain the visual workplace environment. 7. Define the terms associated with the quick changeover process. 8. Identify the changeover techniques used in production. 9. Describe and explain the streamlining process to reduce changeover time. 10. Describe the terms used in overall equipment effectiveness (OEE). 11. Describe and explain the process of total productive maintenance (TPM). 12. Describe and explain tracking process in improving the effectiveness of the operating equipment. 13. Define the terms associated with basic cellular manufacturing concepts. 14. Identify production teams to basic cellular manufacturing and teamwork concepts. 15. Identify steps required to convert to a cellular arrangement. 16. Identify the techniques used in the kanban system for just-in-time (JIT). Course Objectives: 1. a. defining the basic principles of mistake proofing. b. describing and using zero quality control (ZQC) techniques in manufacturing settings. c. identifying mistake proof devices in eliminating errors in manufacturing. 2. a. defining the terms used in the 5S’s. b. identifying and describing the steps used in the 5S’s. c. applying the 5S’s for efficiency, maintenance, and continuous improvement. d. describing the visual workplace environment. 3. a. defining the terms associated with the quick changeover process. b. describing the techniques and approaches used in quick changeover. c. identifying the changeover techniques used in production. d. describing the streamlining process to reduce changeover time. e. developing the line changeover approach in manufacturing. 4. a. defining and describing the terms used in overall equipment effectiveness. b. describing the process of total productive maintenance (TPM). c. defining the role of overall equipment effectiveness in eliminating equipment problems. d. describing the three elements of total productive maintenance as used for the output of goods. e. describing the tracking process in improving the effectiveness of the operating equipment. 5. a. describing one-piece flow for work teams. b. defining the terms associated with basic cellular manufacturing concepts. c. describing the cellular manufacturing layouts that promote production flow by cutting waste. d. identifying production teams basic to cellular manufacturing and teamwork concepts. e. describing the steps required to convert to a cellular arrangement. 6. a. describing the just-in-time (JIT) system. b. identifying the techniques used in the kanban system for just-in-time. c. describing ways of improving the productivity process and quality of the product. d. identifying the non-value-adding activities. c. Describing the 10 step implementation plan. Evaluations: Verification of skills by direct observation, exams. Attendance: Students are expected to be in class and on time every day the class meets. Excused absences will be granted for emergencies and other situations at the discretion of the instructor. It is the student’s responsibility to make up any missed work, including classroom activities and assignments. Schedule of class events: Grading System: TDB Scale 90+ 80-89 70-79 60-69 00-59 Weights A B C D F Tests Lab Skills Reviews Attendance Daily Assignments 40% 40% 10% 10% Assignments are due the beginning of each class on the due date. Grading Scale: A B+ B C+ 90-100 85-89 80-84 75-79 C D+ D F 70-74 65-69 60-64 59 and below Academic Honesty: You may not purposefully deceive any official of the college by cheating on any assignment, examination, or paper. Cheating is the use of anyone else’s work, whether he/she is a student or not, as your own. A student may be withdrawn from this course with the grade of ―”F” if found to have cheated on any course assignments or tests. ADA Statement: Lake City Community College seeks to provide reasonable accommodations for all qualified individuals with disabilities. The college will adhere to all applicable federal, state, and local laws, regulations, and guidelines with respect to providing reasonable accommodations as required to afford equal opportunity. It is the student’s responsibility to register with the Office of Disabled Student Services, located in Building 015, Room 130. (386) 754-4393, and to contact the faculty member in a timely manner to arrange for appropriate accommodations. Withdrawal Procedures: Up until the midpoint of the semester, a student may withdraw without the instructor’s permission. To withdraw up to the midpoint, students should see an Academic Advisor in the Student Development Center, bldg 14 (754-4222) or your advisor on campus. Information on how to withdraw is found on page 45 of the 2008-2009 Catalog. See the Critical Dates Calendar for information on withdrawal. After the midpoint, the student may withdraw only WITH the express permission of the instructor, or the instructor may assign a grade. After the midpoint, instructors may withdraw or assign an F grade to a student for non-participation per instructor’s discretion. Proposed Class Schedule: TBD I, _______________________________, understand and agree to the terms in this syllabus. I am also aware that this syllabus is a tentative schedule and may change with circumstances that happen throughout the semester. I must complete the assigned reading and exercises prior to each class in order to be prepared. Attendance is important as this is a clock hour program. I understand the attendance policy for this course. Student Signature: ___________________________ Date: ____________________ “This product was funded by a grant Community-Based Job Training Grants as implemented by the U.S. Department of Labor’s Employment & Training Administration. The information contained in this product was created by a grantee organization and does not necessarily reflect the official position of the U.S. Department of Labor. All references to nongovernmental companies or organizations, their services, products, or resources are offered for informational purposes and should not be construed as an endorsement by the Department of Labor. This product is copyrighted by the institution that created it and is intended for individual organizational, non-commercial use only.”