July 22, 2011 College of Engineering, North Carolina State

advertisement

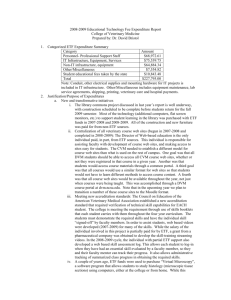

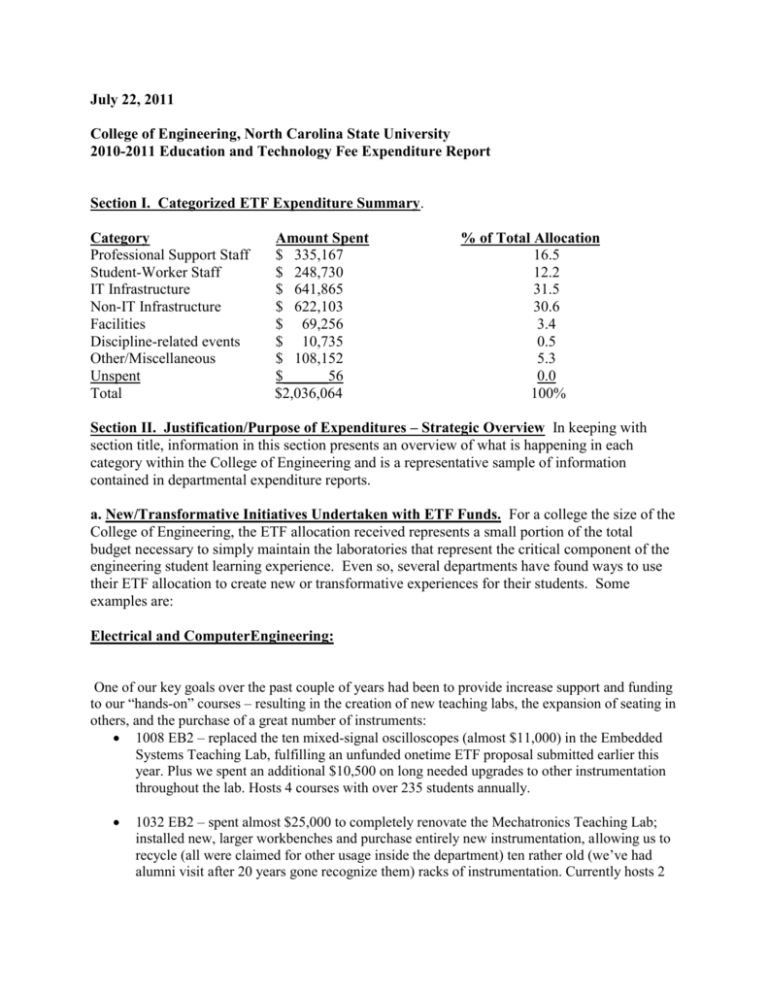

July 22, 2011 College of Engineering, North Carolina State University 2010-2011 Education and Technology Fee Expenditure Report Section I. Categorized ETF Expenditure Summary. Category Professional Support Staff Student-Worker Staff IT Infrastructure Non-IT Infrastructure Facilities Discipline-related events Other/Miscellaneous Unspent Total Amount Spent $ 335,167 $ 248,730 $ 641,865 $ 622,103 $ 69,256 $ 10,735 $ 108,152 $______56 $2,036,064 % of Total Allocation 16.5 12.2 31.5 30.6 3.4 0.5 5.3 0.0 100% Section II. Justification/Purpose of Expenditures – Strategic Overview In keeping with section title, information in this section presents an overview of what is happening in each category within the College of Engineering and is a representative sample of information contained in departmental expenditure reports. a. New/Transformative Initiatives Undertaken with ETF Funds. For a college the size of the College of Engineering, the ETF allocation received represents a small portion of the total budget necessary to simply maintain the laboratories that represent the critical component of the engineering student learning experience. Even so, several departments have found ways to use their ETF allocation to create new or transformative experiences for their students. Some examples are: Electrical and ComputerEngineering: One of our key goals over the past couple of years had been to provide increase support and funding to our “hands-on” courses – resulting in the creation of new teaching labs, the expansion of seating in others, and the purchase of a great number of instruments: 1008 EB2 – replaced the ten mixed-signal oscilloscopes (almost $11,000) in the Embedded Systems Teaching Lab, fulfilling an unfunded onetime ETF proposal submitted earlier this year. Plus we spent an additional $10,500 on long needed upgrades to other instrumentation throughout the lab. Hosts 4 courses with over 235 students annually. 1032 EB2 – spent almost $25,000 to completely renovate the Mechatronics Teaching Lab; installed new, larger workbenches and purchase entirely new instrumentation, allowing us to recycle (all were claimed for other usage inside the department) ten rather old (we’ve had alumni visit after 20 years gone recognize them) racks of instrumentation. Currently hosts 2 courses with 40 students. Upgrades will allow us to add additional courses to this teaching lab. 225 MRC – Spent $13,000 on an LCR meter required to complete upgrades to the laboratory utilized by ECE 557 (an additional $30,000 was secured via onetime funding – details below). Currently hosts 1 course with 10 students. New instrumentation will allow development of future experimental modules for the undergraduate nano course (ECE 445) which would add another 20 students. Replaced the computers in four of our teaching labs -- Analog and Digital Circuits Teaching Lab, Distributed Controls Teaching Lab, Robotics Teaching Lab, and our newly created Biomedical Instrumentation Teaching Lab. Chemical and Biological Engineering: Acquisition of Two New Teaching Experiments. Undertaken to meet rising undergraduate enrollment in 2010 and beyond and to improve and upgrade the teaching of the lab courses, CHE 330 and CHE 331. The acquisition of the two new teaching experiments–Boiling Phenomena Experiment and Fluidization Phenomena Experiment–will substantially expand the laboratory capacity of CHE 330 that is the bottleneck for student enrollment in the CBE program. With these two new experiments deployed in 2011-2012, the laboratory course enrollment can increase by up to 40% (from 100 to 140). Computer Science: NetLabs Virtual Computing Network: Laboratory experiments accompanying instruction in computer networking courses require access to diverse networking hardware (“switches”) and complex systems of programs (“software”) to set policy and utilize such hardware. Of late, increasingly the functioning of networks is driven by software, running on commodity hardware. This has also prompted an explosion of such software systems, and it is desirable that our graduates have exposure to a large number of such systems. Many such systems are available freely or as open-source alternatives, but require comparatively powerful computers and network switches. CSC networking faculty have developed or adapted a series of such software environments that the students can use to have experience with a "network-in-a-box", with end stations, intermediate nodes, switches and routers operating as virtual machines inside compute-powerrich servers. At this time, the list of such environments includes: OpenFlow, SILO, Mesh Wireless, Networking kernel, Motorola Droids (Google/Android). We plan to add the GENI control frameworks such as ORCA in the near future. All of these require the ability to save and load images, and map virtual interfaces to real networking interfaces and connect to real switches. Previously students had to run the system on their own laptops, which severely limited them. The purchased equipment resides in the networking labs in flexible configurations, and obviates that problem for the large body of our students. The new facility allows students to have a broad range of experiences, in addition to the specific experiments that can be performed by procuring dedicated equipment. It will be more futureproof, since the hardware (servers and switches) will be commodity and it will be possible to upgrade them over time in small increments, and upgrading to new software systems as they become prominent in the world of practice will require orders of magnitude less time, effort and cost. Thus our students will have much more up-to-date and relevant instruction and hands-on experience. It will also be possible for the equipment to be “reset” between use by various students and student groups – since the system is virtual, even after a disastrous misconfiguration or mistake by one student, the “base state” will be possible to restore in a matter of minutes (whereas in a system with dedicated and/or special purpose hardware, this may require days of highly skilled effort by instructors, TAs, or lab support personnel). Thus the students will have the advantage of a highly resilient and available lab. Student utilization will average 550 undergraduate and graduate students each year, as below. Number of students per section is averaged over year. CSC 401 – 2 sections, 50 students each CSC/ECE 570 – 4 sections, 60 students each CSC/ECE 573 – 3 sections, 50 students each CSC/ECE 575 – 2 sections, 40 students each Android-Ready Phones: After successfully using Android phones in CSC216 in the Spring and Summer of 2010, we expanded our investment in the number of Android devices available to students. Programming mobile devices has immediate student impact because most students use cell phones and smart phone everyday, and mobile programming provides interesting design and complexity problems. By CSC216, students know the basics of programming, specifically in the Java programming language, and how to use APIs. The Android SDK is a robust Java library for developing mobile applications and would be applicable in teaching key CSC216 concepts (inheritance, abstraction, interfaces, and polymorphism) within a concrete and emerging programming paradigm. Additionally, students would be exposed to the end-to-end development process with a concrete product. Thanks to ETF funding from 2009, We purchased 30 ADP1s for use in Spring of 2010. A gift of 30 Motorola Droids from Google was able to double the number of devices we can use in CSC216. However, there were not enough devices for each student to use one. Instead, students were put in teams, and one phone was checked out to a team member for the semester. There were two limitations to that situation: Teaming was not appropriate at the CSC216 level. Additional devices could support paired or solo assignments, and research into the appropriateness of teaming/pairing in CSC216. We are potentially limited to projects that can run on a single device rather than projects that allow for communication between two or more devices. Additional devices will help support the larger enrollment of CSC216 students in the fall, smaller teams, communicative applications, while maintaining backup devices and devices for the teaching staff for the course. Mobile application development is an emerging paradigm in computing. Most students carry smart phones, and the phones they do carry tend to have advanced functionality. With the provided ETF funds, I was able to purchase 28 Nexus One Android phones for student use within CSC216. CSC216 is the second semester programming course within the Department of Computer Science. Students enter the course with the fundamentals of programming (procedural decomposition, conditionals, loops, arrays, and file I/O). CSC216 builds on the intro course by introducing advanced object-oriented (OO) programming concepts like inheritance, abstraction, interfaces, and polymorphism. Students are also introduced to linear data structures (array-based lists, linked lists, stacks, and queues), recursion, and finite-state machines. By introducing mobile application development via the Android platform, students were able to apply the learning objectives of CSC216 on “real-world” programming projects. Mobile applications are typically small, which makes them feasible assignments within the CSC216 course. Additionally, students were able to apply other software engineering principals during development: teaming, testing, design, version control systems, and using a 3rd party API and library. The Nexus One phones were additionally used in the College of Engineering’s High School Summer Programs Computer Science Workshop during the weeks of June 20th and June 27th. Fifty-nine students participated in the two one-week workshops and developed Android applications using AppInventor. The students demoed the apps they created for family and friends at a poster session at the end of the workshop. The Nexus One phones allowed for development of more complex applications that take advantage of the latest versions of the Android operating system. CSC216 students in the Fall of 2010 and Spring of 2011 were assigned projects that required the students to write Android applications to evaluate the course learning objectives. While there was some difficulty with students understanding of the Android libraries, overall the use of Android phones maintained the current level of student learning in CSC216, especially in the Spring 2011 semester. Cloud Computing Technology Teaching Laboratory: In May 2010 we completed initial equipment installation and testing of our new Cloud Computing Technology Teaching Laboratory. During this past academic year we continued the development of our lab. The CCTT lab is a departmental teaching resource based on Virtual Computing Laboratory infrastructure that is used to provide a hands-on virtual laboratory facility for teaching our students about Cloud Computing technologies, multi-core, virtualization, related security, operating systems, etc. As technology changes our course content is changing. These changes are quite encompassing – they cover our undergraduate and graduate courses. We are currently lagging behind our peers in ability to teach students about the latest technologies because we do not have access to the latest range of multi-core and virtualization resources within VCL. We are proud to have closed that gap with the establishment of our VCL-based CSC Cloud Computing Technology Teaching Laboratory (a virtual facility accessible from anywhere and anytime). The facility uses the latest suite of Nehalem chip based IBM blade technology with considerable amount of memory. Specifically, we installed a additional chassis of 14 HS22 blades running in 10Gbps communication matrix. The equipment is integrated into VCL and the CSC CCTTL is available on-demand to CSC instructors and students. This virtual laboratory is having a tremendously beneficial impact on our students – ranging from sophomores to seniors. It provides knowledge and skills that will keep our students competitive and employable in the context of the new generations of information technology and computer science advances. The CCTTL equipment is used in at least 7 undergraduate and graduate courses. Courses include: CSC 246: Concepts and Facilities of Operating Systems for Computer Scientists CSC 501: Operating Systems Principles CSC 405: Introduction to Computer Security CSC 548: Parallel Systems CSC 440: Database Management Systems CSC 450: Web Services CSC495c: our new Cloud Computing course CSC/ECE 506: Architecture Of Parallel Computers Student enrollments using the equipment in one year averaged 526. Industrial and Systems Engineering: With the advent of low cost methods of design and manufacture, much innovation has been seen across all of the core engineering disciplines. Those interested in realizing their designs are turning to IEs (notably this department) to offer advice and gain insight into the many manufacturing methods that are currently available. The ISE Department serves a vital role in bridging the design and engineering communities. With such interest and growth already seen in mass customization, the department is realigning its manufacturing course sequence to better serve students. Faced with decreasing budgets and increasing enrollments, one way to serve more with less is to ensure labbased equipment is: i) affordable, ii) multi-purpose/multi-tasking, and iii) scalable. To this end, present and near-term procurement strategies will continue to keep these objectives in mind when leveraging ETF-based investments. This year’s base allocation was supported by a one-time allocation used to create a new laboratory (Additive Manufacturing Extension Laboratory) that will highlight the use of three-dimensional printing technologies. The lab will serve students from across the College, allowing them the ability to design and prototype products. A key component of creativity, innovation and entrepreneurship, this equipment will allow current students, summer camp attendees (largely high school students) and freshmen an opportunity to experience this technology first-hand. Borne out of space issues occurring in the existing Rapid Prototyping Lab, a teaching laboratory maintained by the ISE Department, AMEL will be used in both teaching and research domains, serving over 350 First Year College and ISE students requiring such resources for course study and group project needs. The reach of ETF funding is broad. The ISE Department delivers four manufacturing-related undergraduate and at least five graduate courses each semester that benefit from ETF allocations. Technology supporting classroom instruction, group and individual projects in the following courses leverage ETF on a yearly basis: ISE 216 Mfg. Engineering Practicum ISE 316 Mfg. Processes ISE 416 Mfg. Automation ISE 498 Senior Design Project ISE 514 Product Engineering ISE 515 Process Engineering ISE 544 Occupational Biomechanics ISE 589 Intro. to Medical Device Design ISE 589 Direct Manufacturing ISE 716 Automation Engineering ISE 741 Occupational Safety Eng. ISE 789 Mfg. Planning & Control ISE 789 Nano/micro Scale Fabrication ISE 789 Computational Geometries ~48 students per year ~40 students per year ~40 students per year ~45 students per year ~10 students per year ~30 students per year ~30 students per year ~10 students per year ~20 students per year ~30 students per year ~20 students per year ~10 students per year ~10 students per year ~10 students per year ISE 789 Mfg. for Medical Devices ~10 students per year for Design & Mfg. Civil, Construction and Environmental Engineering: A description of the major acquisitions made during the 2010/2011 academic year is listed below. ETF funds are being used to maintain and improve laboratories that expose students to modern engineering tools through hands-on experiences. In the field of Civil, Construction, and Environmental Engineering, this includes a combination of experimental and computing laboratory experiences. To maximize the impact of ETF funds on the department’s teaching program, funds that remain after expenditures for routine supplies and maintenance are pooled to fund one or two major improvements. When possible, ETF funds are combined with outside donations to maximize the impact on the department’s teaching program. Example initiatives that were funded by a combination of ETF and outside funds over the last years include the implementation of a computerized classroom, the overhaul of the construction engineering computer laboratory, the implementation of a new construction engineering laboratory, and the acquisition of materials for a sensor network. Seven large format computer monitors and mounting brackets ($10,466) were purchased with ETF funds. Six monitors are located in the Mann Hall lobby and the undergraduate student lounge to allow students to work on group projects. One monitor is located in Mann 109, where the monitor is used with laboratory exercises involving the use of microscopes and image analysis software. For the Transportation systems area, ETF one-time funds ($40,000) were used to purchase 10 BluFax traffic surveillance devices. The devices will be used in undergraduate and graduate transportation systems courses, including the capstone design class. Approximately 270 undergraduate and 80 graduate students will benefit from the availability of the traffic surveillance devices. Affected courses: CE305, CE400 (capstone design), CE401/501, CE402/502, CE403/503, CE506, CE701, CE702, and CE706. For the Transportation systems area, ETF funds ($21,204) were used to purchase (1) two omnidirectional cameras, (2) two RTMS G4 traffic detectors with pole mount solar system for operation, (3) a mast for mounting traffic detectors, and (4) two intersection count boards. Approximately 270 undergraduate and 80 graduate students will benefit from the availability the new equipment. Affected courses: CE305, CE400 (capstone design), CE401/501, CE402/502, CE403/503, CE506, CE701, CE702, and CE706. For the Structural Engineering lab, ETF funds ($15,332) were used to purchase materials and equipment for the construction of two additional lab stations that were required to accommodate increased enrollment in CE324 (Structural Engineering Laboratory). ETF funds ($30,768) were used to purchase four Geo/Jac systems for the undergraduate geotechnical engineering laboratory (CE342). With the new equipment, CE342 students have access to modern equipment used for testing soil compressibility. For the Environmental Engineering lab, ETF funds ($4,964) were used to support six pH meters with solid-state probes. The pH meters are replacing aging units equipped with glass probes that were prone to breakage and needed to be replaced frequently. Biomedical Engineering. ETF funds were used to purchase an artificial muscle-tendon system which is operated by the electrical signals measured from muscles (EMG). The system include 8 channels for EMG measurement, a software and hardware package for real-time robotics development, a 4 proportional pneumatic control valves for controlling the artificial muscles. The equipment will primarily be used to develop a new Bio-Robotics course. Bio-Robotics is an emerging area of growth in the engineering sector. It is an excellent topic for teaching Biomedical Engineers because it involves the intersection of controls engineering, biomechanics, electronics design, mechanism design and physiology- all areas of core emphasis in the BME undergraduate curriculum. Perhaps more relevant is the myriad ‘real-world’ problems that can used to motivate student interest. Hands-on instruction based around topics ranging from: prosthesis design and optimization, direct brain/muscle interface, wearable robotics, assistive devices for the disabled and even ‘avatar-like’ gaming systems can be employed using the system. In addition to the Bio-Robotics course which is in development, the equipment was used as part of a lab exercise for BME 201 (20 students in spring, 55 per year in the future) and as a teaching demonstration for outreach as part of the Engineering in Medicine Summer Camp. Nuclear Engineering. The renaissance that is currently taking place in the nuclear power industry has created an increased demand for nuclear engineers and a corresponding increase in enrollment in the nuclear engineering program. The department has used a combination of recurring and one-time ETF funds as well as matching grants from industry and federal sources to begin to upgrade and expand teaching laboratory facilities. The Plasma and Thermal Hydraulic laboratories have been upgraded with new computers, multichannel analyzer cards, analog to digital cards and digital oscilloscopes. Radiation detection equipment was acquired to support spectroscopy and coincidence measurements. Amplifiers and proportional counters were also acquired. b. Actions Taken to Improve Efficiency/Return on Investment of ETF Funds. Throughout the college, departments receiving ETF funds continually seek ways to stretch and multiply the effects of the ETF investment. Some examples are: 1. Collaboration: Several engineering departments work together to collaboratively acquire or use expensive laboratory equipment. BME chose to work out an agreement with MAE to use an existing MAE lab that contained test equipment that had been requested for purchase by a BME faculty member rather than buying another set. MSE and CBE collaborated on the purchase of a Scanning Electron Microscope to be used by students in both departments. ECE and CSC jointly support and use the Master of Science in Computer Networking laboratory. Collaboration between MSE, CBE and ITECS resulted in the consolidation of two Eos computing labs into one student computing area located in previously underutilized space. This resulted in much better space utilization and a lowering of Eos laboratory support requirements. 2. Competitive Pricing: We continue to use all source available to us to locate the lowest price for equipment including Marketplace, surplus, and 2nd hand sources. When possible, we negotiate for bulk and/or educational discounts. 3. Departmental Matching/Donations: Many departments match ETF allocations with funding and equipment donations from industry and private sources, thus increasing the reach and usefulness of ETF dollars. Many of these matches are identified in our request for one-time ETF resources. 4. Use of “industry standard” equipment: Where possible, departments purchase and students use test and fabrication equipment that is “industry grade.” The intent is to make the student experience more meaningful and useful as they learn to use equipment they will actually encounter once they have entered the workforce in their chosen field. This equipment tends to be more robust, resulting in greater reliability and more compatible with equipment that may be donated by industry. 4. Leveraging Technological Advances: Increasingly, older analog laboratory instrumentation is being replaced by digital or software based instruments. While acquiring these new instruments requires substantial investment, these investments pay off in reduced maintenance costs and generally longer life cycles. Additionally, many of these instruments are accessible via web interfaces. This enables many more students, to include distance education students, to access and control these instruments. In the case of BME, students located at UNC-Chapel Hill are able to observe and manipulate instruments physically located at NC State. This reduces the need to duplicate instruments in both locations and saves students travel time and expense to participate in labs. 5. Complete Lifecycle Management: All departments aggressively pursue equipment lifecycle plans that repurpose older equipment in various ways. For instance, when ITECS replaces older computers in Eos Computer Labs, those computers are then offered first to COE departments for their use and any that are left over are offered to other colleges. While those computers may not be suitable for computer labs they are useful for conducting experiments, equipping student workspaces and for spare parts for other machines. Many displaced UNIX lab machines are currently being used to increase the resources of the Virtual Computing Lab. Only when machines are completely useless are they sent to surplus. 6. ETF Resource Management: This year the College of Engineering implemented a new ETF management process that enabled us to do a better job of ensuring ETF resources were spent. Departments were required to spend or obligate their ETF resources by April 1. Any unspent/unobligated resources after April 1st were consolidated at the college level and reallocated to one-time projects. As a result, unspent ETF resources totaled $55.81 this year. c. Unmet ETF-Eligible Needs. The College of Engineering continues to experience substantial growth in most of its programs. This growth places a strain on all teaching facilities but in particular results in overcrowding in discipline-specific teaching labs, increased consumption of materials and supplies to support the labs, increased maintenance costs to keep durable equipment in operating condition and a more rapid degradation of machinery and instrumentation due to more continuous use. All of these factors result in a need for more resources to accommodate our students’ learning. In particular the Nuclear Engineering department is experiencing a rapid growth in enrollment due to the resurgent interest in nuclear power. This has resulted in a need to replace outdated equipment and equip new teaching labs to accommodate said growth. Some examples of currently unmet needs follow: BioMedical Engineering: With the move to Engineering Building III complete the department now has the space to expand their teaching laboratories to better accommodate their students. The department has identified roughly $85K in laboratory equipment that it needs to acquire and for which ETF would be a suitable resource. Chemical and BioMolecular Engineering: $35,000 is needed to develop a biochemical engineering experiment, the first of its kind in the CHE curriculum. Industrial and Systems Engineering: Inert Atmosphere Heat Treating Furnace Unmet Need: $25,000 Processing of today’s engineering materials requires the use of surface and heat treatments in order to enhance the performance of the wrought alloys used. In line with the Department’s goal to incorporate materials-based laboratories within the curriculum, an atmosphere heat treating furnace is needed to realize many functional components that are now commonplace, and to extend the research being done in these areas. Similar to the curriculum being developed for materials testing, use of this equipment will be prevalent throughout the undergraduate and graduate manufacturing courses and research projects alike. Multi-Sensor 3D Measurement and Inspection System Unmet Need: $87,000 In manufacturing, product inspection is an important step in the production process. To ensure 0% defects, as is often a requirement in FDA, FAA and many MIL applications that every part be inspected for compliance. When coupled with scale factors that transcend human abilities and the ever-persistent high cost of manual inspection, machine-based inspection becomes a necessity. North Carolina’s economic frontier will rely on industries such as medical, aerospace and energy. The ISE Department, positioned for meeting the need of tomorrow’s workforce, currently performs touch-based reverse engineering and inspect-to-CAD activities in many of its manufacturing courses, extending into research. Particular items that currently pose roadblocks are small feature (<1mm) measurement and part resiliency. Non-contact measurement overcomes such difficulties. These systems combine vision, laser and tactile probing and allow for multi-mode inspection of microfeatures; capabilities not presently available in the department. Locating a multi-sensor 3D measurement and inspection system within the College will enable the ISE Department to teach students, undergraduate and graduate alike, about the ever-increasing use and benefits of these technologies and will also supplement research efforts in the areas identified above. Item: 6-Axis Articulated Robot with Advanced Trajectory Processing Unmet Need: $79,000 As previously stated, great transformation is occurring in North Carolina’s manufacturing sector. Two areas that hold great economic potential for the state are the aerospace and energy sectors. The ISE Department, positioned to meet the needs of tomorrow’s workforce, currently maintains a state-of-the-art processes laboratory where industry-standard CNC machines for small part production are well represented. By nature of the machines, the ability to process large parts is lacking. Furthermore, the type of processing is limited to traditional cutting and erosion methods, not necessarily suitable for components required in the industries mentioned above. In 2009-2010, the ISE Department made great strides to enhance its instruction in robotics; two 6axis articulated robots were purchased with ETF funds and subsequently placed into service to illustrate the economy of robotics in pick-and-place, palletizing, material handling and inspection. In particular to aerospace industries, i) coating applications, ii) welding, iii) grinding, iv) polishing and v) trimming, are still underrepresented processes in the curriculum. When complemented by the processes already existing in the lab spaces, an example of a complete manufacturing system can be shown and used as a teaching and research platform. It is of high value for all ISE students to discover these attributes as they model and build real systems in the ISE’s lab spaces. Item: CNC Turning Center with Live Tooling Unmet Need: $106,000 The ISE Department currently maintains several CNC material processing devices that are geared toward teaching the practices of modern-day machining of small component parts. One piece of equipment, known as a turning center, removes material about a central axis of rotation. Three of these devices exist in the main Processes Laboratory and are heavily utilized each semester. One of the machines is reaching its end of useful life. The parent company has since gone out of business, making parts procurement and service difficult. One shortcoming of all machines of this type located in the department is the inability to process components with three degrees of freedom. To do so, the parts must be moved from machine to machine in order to produce asymmetrical features. This point identifies a significant gap in the technology currently used in the Manufacturing Processes Lab. A CNC turning center with “live” tooling allows for multi-axis machining with no change of setup; a key benefit and crux of many teaching examples that serve to underscore setup time reduction. Flexible/agile manufacturing is the creed of the modern-day manufacturer. The addition of this type of machine would greatly enhance both undergraduate and graduate courses. Nuclear Engineering: Diagnostics and other equipment in the plasma laboratory are still needed. While the number of students utilizing the lab was relatively small in the past, the number is increasing due to the addition of new faculty members. The recent Nuclear renaissance created a lot of enthusiasm in the community resulting in increased numbers of undergraduate and graduate students. Unfortunately, adding labs for a greater number of students requires additional equipment. Purchases are being made every year at the ~$20K per year level, but additional funds will be needed to be fully functional. The one-time allocation of $14K this year will be of definite help while continued funds are required to repair and maintain the current high vacuum equipment to be operational as well as for upgrading them. There is still a need to increase the number of radiation laboratory stations especially due to the sudden increase in the number of students in NE. There have been student requests to replace all of the older (but functional) equipment in the radiation laboratory with new equipment. We did procure new power sources and other parts in 2010-11 while additional funds are needed to upgrade all lab stations. There are several new experiments that need to be added to the thermal-hydraulics laboratory and with the increase in student enrollment, additional laboratory stations are desired. As mentioned in last year’s report two additional stations are needed to make the facilities suitable for the increased enrollment while one station has been approved and acquired during this fiscal year from one-time funding received in 4/2011. d. Assessment of Impact of ETF Investments on Student Learning. Ultimately, the impact of ETF investments in the College of Engineering is reflected in the college’s growing stature among its peers in terms of a positive jump in national and international rankings of the college and several academic departments. Further, most of the college’s ETF funding goes directly or indirectly to the support of discipline-specific teaching laboratories. Because ETF allows us to maintain those labs in a relatively healthy state they become attractive resources for recruiting top-notch faculty and top-notch students. More specifically, departments assess the impact of ETF on student learning in various ways including: 1. Student Surveys. Several departments have ETF or laboratory committees that have developed and implemented surveys of students who use the labs. These surveys assess the students’ satisfaction with their laboratory experience and solicit suggestions for improvements. 2. Student Success. Most departments reported using student grades in laboratory courses as one indicator of how well the laboratory experience was supported. 3. Focus Groups. The ITECS Student-owned Computing group recruits a standing focus group of engineering graduate and undergraduate students to provide feedback on various topics related to SOC. Several times a year, aspects of ETF supported computing labs and other initiatives are discussed and suggestions solicited from these groups. 4. Feedback from alumni, discipline-related industry and accrediting organizations. The college and departmental leadership are very active in collaborating with alumni and industry to determine how prepared our graduates are to enter the engineering profession. Information from these interactions are fed back into curriculum and laboratory committees and helps guide the acquisition of equipment and revision of curriculum to meet the changing needs of the “real world.” Additionally, feedback from accrediting agencies is also input into the process to ensure that the college continues to meet the standards set by those agencies. All of these indicators provide us with evidence that the college and departments are doing a good job of using scarce ETF funds to multiply and extend the teaching resources that exist within each department. Students indicate they are happy with the modernization and expansion of teaching labs facilitated by ETF but would like to see more done more quickly. There are several areas where departments have identified shortfalls through preparation for accreditation visits and have taken steps to apply current ETF resources and where necessary to request additional resources to resolve the issues. Several departments are experiencing rapid growth in the number of undergraduate and graduate students enrolling in their programs and need additional resources to expand or develop labs to accommodate that growth. e. Planning and Review Process. The College of Engineering administers its ETF resources in a decentralized manner, the belief being that the closer to students the decision-making is the more likely that those resources will be used to directly support students. Each academic department and ITECS receives a predictable portion of the college’s base allocation. Each department has an ETF committee that incorporates student members and student input in the decision-making process. As all of ITECS ETF funds goes to support Eos computing labs, the Assistant Director, Eos Lab Manager, student lab operators and SOC personnel collaborate to plan for the expenditure of ETF in support of the Eos labs. The college also has an ETF advisory committee with representatives from each department and ITECS. This committee ensures ETF plans are maintained and prioritizes one-time requests for forwarding to the university ETFAT. Finally, each department prepares and submits an ETF expenditure report in the same format as this report. Each report is reviewed by the Assistant Dean for Finance and by the college’s ETFAT representative. Information from these reports is condensed and consolidated to create the college’s expenditure report. The AD for Finance also monitors ETF expenditures throughout the year and when necessary consults with the ETFAT representative to ensure potentially questionable expenditures meet the criteria established for ETF use. Section III: Summarized List of Expenditures by Account Code COLLEGE OF ENGINEERING (ETF) EDUCATION AND TECHNOLOGY FEE EXPENDITURE REPORT SUMMARY 2010-2011 Account 51112 51117 51119 51219 51270 51311 51319 51410 51450 Total Salaries 51811 51813 51821 Description Grad. Res. Asst. EPA NON-TEACH ANNUAL LEAVE PAY Epa Reg -all Other Spa-reg. Salaries Spa Longevity Pay Grad. Teach. Asst. Epa Teach-all Other Non-student Reg Wage Student Regular Wage Social Security Federal Health Ins State Retirement Total 1,898.07 0.00 19,612.08 156,296.52 289.15 8,177.90 48,317.77 68,620.25 216,492.48 519,704.22 17,906.03 4,187.66 19,588.77 51830 51831 51871 51873 51891 Total benefits Medical Insurance Grad Health Insurance (ghi) Tiaa Optional Ret Optional Retirement Plan Staff Benefits 14,389.44 68.30 2,608.35 2,066.78 3,378.11 64,193.44 52101 52205 52300 52301 52400 52450 52510 52590 52600 52650 52821 52823 52824 52826 52850 52870 52872 52873 52874 52875 52900 Total Supplies Household Sup-janitorial/cln Food Products Educational Supply Athletic Medical Repair Supplies. Maintenance Equipment Gasoline/diesel Fuel Other Mtr Veh Suppl Office Supply Data Processing Supplies Other Comp Software <$5,000 PC Software Purch <$5,000 Server Software Purch <$5,000 External Dev Software <$5,000 Other Equip-Voice Comm <$5,000 Other DP Equipment <$5,000 Video Trans Equip <$5,000 LAN Equipment Purch <$5,000 PC & Printer Purch <$5,000 Server Purchases <$5,000 Other Supply 53112 53121 53124 53125 53129 53141 53144 Total Travel In-state Transportation-Ground Out Of State Trans-air Out Of State Sub-lodging Out Of State Subsistence-meals Out-of-state Registration Fees Board/nonemp Travel-trans Board/nonemp Travel-sub 1,195.15 0.00 299.76 139.90 105.00 1,390.30 1,630.31 4,760.42 53210 53230 53272 Telephone Service Comm-telecomm Services Telephone Wiring Service Charg 54.16 50,695.08 2,948.60 523.86 0.00 458,273.39 69.65 14,676.77 10,658.85 30.00 4,781.70 49,070.11 2,680.42 17,162.30 11,148.54 6,631.98 5,585.00 31,579.09 26,376.46 1,372.96 29,054.24 158,549.71 6,238.77 48,695.30 883,159.10 53400 53510 53540 53550 53590 53600 53810 53811 53923 53924 53925 53926 53929 53951 Total Current Services Printing And Binding Repairs Bldg/gnds Repairs- Other Computer Equip. Repairs And Maint-oth Eq Repairs And Maint Freight And Express Computer/data Process Svs Managed LAN Service Charge Svs Agree-lab Svs Svs Agree-janitorial Svs Agree-waste Remove Svs Agree-security Svs Service Agreements-other Employee Training 456.26 37,688.34 1,089.00 9,376.01 465.78 3,126.80 3,000.00 11,000.00 3,019.00 382.14 289.13 5,854.03 0.00 1,162.50 54350 54371 54420 54437 54438 54439 54513 54991 54998 Total Fixed charges Rent Of Oth Equip-other Rent/Lease - Server Software Maint Contract-other Equip Maint Agrmt - PC Software Maint Agrmt - Server Software Maint Agreement - Servers Insurance-liability Royalties Other Fixed Charges 3,237.62 2,808.00 4,800.00 65,624.99 47,532.42 3,212.28 10,000.00 (1,160.00) 286.98 136,342.29 55110 55210 55223 55224 55226 55320 55330 55529 55570 55575 Total Equipment Off Equip-furniture Edp Hardware PC Software Purch >$5,000 Server Software Purch >$5,000 External Dev Software >$5,000 Educ Equip-scientific/medical Educ Equip-egr Draft Eq Oth Eq - Misc. Other DP Equipment >$5,000 Server Equipment >$5,000 0.00 0.00 7,520.00 1,000.00 12,894.67 47,756.52 41,658.00 17,300.32 40,000.00 129,112.38 297,241.89 130,606.83 Total Expenditures 2,036,008.19