Homework 7 - Devin Gatherwright IET 307 Portfolio

Devin Gatherwright

11/2/2012

IET 307: Materials Science

HW 7 (based on chapters 12 & 13)

Due by 11.55 PM, Wednesday, November 7’Th, 2012

100 points

1. What are the AX-Type crystal structures? Explain the rock salt structure, cesium chloride structure & zinc blende structure in a few sentences and then draw a schematic of each structure. (10 points)

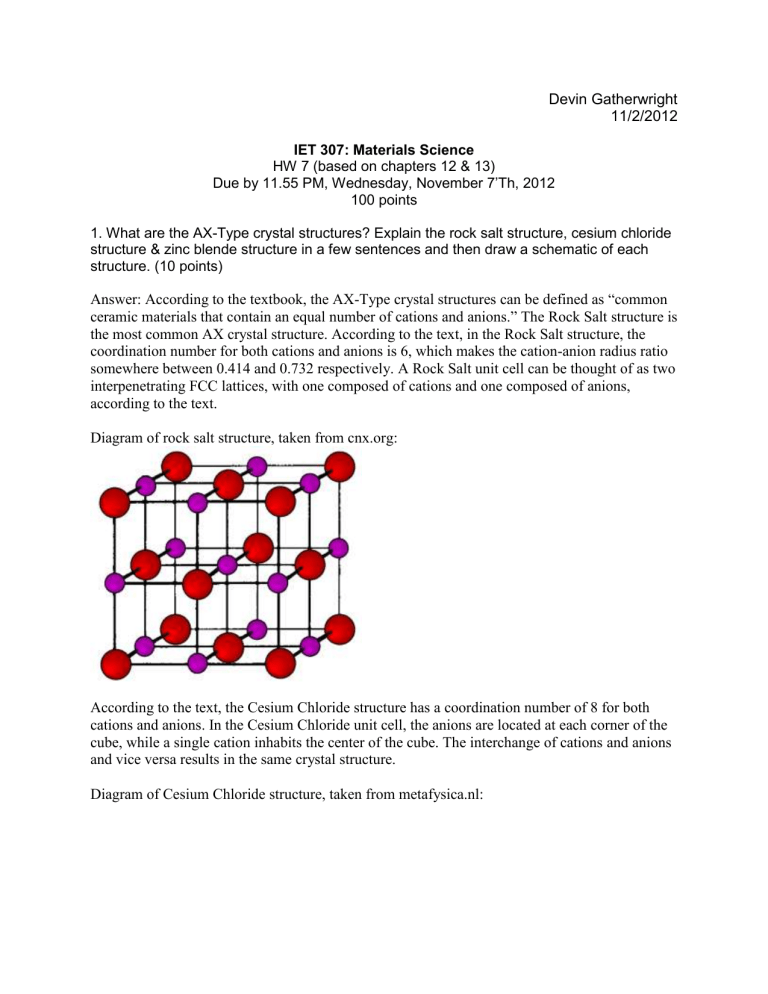

Answer: According to the textbook, the AX-Type crystal structures can be defined as “common ceramic materials that contain an equal number of cations and anions.” The Rock Salt structure is the most common AX crystal structure. According to the text, in the Rock Salt structure, the coordination number for both cations and anions is 6, which makes the cation-anion radius ratio somewhere between 0.414 and 0.732 respectively. A Rock Salt unit cell can be thought of as two interpenetrating FCC lattices, with one composed of cations and one composed of anions, according to the text.

Diagram of rock salt structure, taken from cnx.org:

According to the text, the Cesium Chloride structure has a coordination number of 8 for both cations and anions. In the Cesium Chloride unit cell, the anions are located at each corner of the cube, while a single cation inhabits the center of the cube. The interchange of cations and anions and vice versa results in the same crystal structure.

Diagram of Cesium Chloride structure, taken from metafysica.nl:

According to the text, the Zinc Blende structure has a coordination number of 4, with both the cations and anions being tetrahedrally coordinated. In a Zinc Blende unit cell, all face and corner positions of the cube cell are inhabited by S atoms, with the Zn atoms filling up the interior tetrahedral positions, according to the text. An equivalent structure can also be formed if the Zn and S atoms positions are reversed. Therefore, each Zn atom in the unit cell is bonded to four S atoms and vice versa.

Diagram of Zinc Blende structure, taken from everydayscience.com:

2. Explain in a few sentences for each of the following ceramic materials, their properties and applications (10 points).

(a) Lead zirconium titanate

(b) Cordierite

(c) Barium titanate

(d) Zirconia

Answer: According to the text, the lead zirconium titanate exhibits the unusual phenomenon that is known as piezoelectricity, which is when an electric polarization is formed in the ceramic crystal when a mechanical strain is imposed. According to the text, lead zirconium titanate can be used as a transducer between electrical and mechanical energies due to this unique property.

Lead zirconium titanate can be used in sonar equipment, automotive wheel balances, seat belt buzzers, tread-wear indicators, airbag sensors, keyless door entries, ink-jet printing heads, and smoke detectors.

According to the Wikipedia.org article on cordierite, cordierite is a “magnesium iron aluminum cyclosilicate”, and is commonly found in the “metamorphism of argillaceous rocks”

(Wikipedia.org). According to Wikipedia.org, cordierite are commonly used in catalytic converters due to their high shock resistance (Wikipedia.org).

According to the Wikipedia.org article on barium titanate is an “inorganic compound” with the chemical formula “BaTiO

3

” (Wikipedia.org). According to Wikipedia.org, barium titanate is a white powder and is transparent in color. Furthermore, according to Wikipedia.org, barium titanate is ferroelectric ceramic material, and has both piezoelectric properties and photorefractive effects (Wikipedia.org). According to Wikipedia.org, barium titanate is used in transistors, microphones, transducers, and nonlinear optics (Wikipedia.org). According to

Wikipedia.org, barium titanate is dielectric ceramic, meaning in has electrical insulation properties (Wikipedia.org).

According to the Wikipedia.org article on zirconia, zirconia is a “white crystalline oxide” or zirconium, and has a high thermal stability and is chemically unreactive (Wikipedia.org).

According to Wikipedia.org, zirconium is used primarily in the production of ceramics and as a protective coating on titanium dioxide particles (Wikipedia.org). Furthermore, according to

Wikipedia.org, zirconium has a high ionic conductivity and a low electronic conductivity, which makes it a quite useful electroceramic.

3. What material is used to make the tiles that provide thermal protection in NASA’s space shuttle? What properties of this material enable it to be used at very high temperatures?

Why is the tensile strength of ceramics much lower than that under a compressive stress?

(10 points)

Answer: According to the ehow.com article “Physical Properties of Space Shuttle Ceramic Tiles,” there are several different types of tiles used on space shuttles. These different types include: reinforced carbon-carbon tiles; high temperature reusable surface insulation tiles; fibrous refractory composite insulation tiles; and low temperature reusable surface insulation tiles (ehow.com).

According to the article, most of the aforementioned ceramic tiles are composed of silica, except for the carbon-carbon tiles, which are mainly used for the re-entry into Earth, according to the article.

According to the textbook, silica refractories are well-known for their ability to withstand high temperatures without melting or decomposing, as well as their ability to bear large loads at high temperatures. This unique property is due to the fact that refractories are composed of both fine and large particles, with both contain different compositions, according to the text. When these particles are fired upon, the fine particles get involved in the formation of the bond phase, which helps induce heightened strength in the refractory brick. Also, another property that enables silica refractory tiles to be used on space shuttles is the reduction in porosity of the silica refractory ceramic tile.

According to the book, the strength, load-bearing capacity, and resistance to corrosion are all drastically involved when the porosity of the material is reduced, those giving silica its unique properties. The tensile stress of ceramics is lower than that under a compressive strength due to the fact that ceramics are brittle, and therefore have low ductility.

4. On the basis of crystal structure, compute the theoretical density for manganese sulphide

(MnS). How does this compare with its measured density? (Hint: See example problem 12.3 on page 463 of your text book) (10 points).

Answer: 𝑝 = 𝑛 ′ (∑ 𝐴

𝐶

+ ∑ 𝐴

𝐴

)

𝑉

𝐶

𝑁

𝐴

𝑝 =

4 (54.94+32.06)

[2(0.067 𝑋 10 −7 )+2(0.184 𝑋 10 −7 ) 3 ](6.022 𝑋 10 23 ) 𝑝 =

348

76.18

𝑝 = 4.57 𝑔/𝑐𝑚 3

According to manganese sulfide article on Wikipedia.org, the measured density of manganese sulfide is 3.99 g/cm

3

, so my computed value is close.

5. Discuss the various polymorphic forms of carbon and its properties. 10 points)

Answer: According to the textbook, there are three types of polymorphic forms of carbon: diamond, graphite, and fullerenes. According to the textbook, diamonds are metastable carbon polymorphs at mild temperatures and atmosphere pressure respectively. Furthermore, the crystal structure of a diamond is an alternative of zinc blende, which is where all positions are occupied by carbon atoms. In diamonds, carbon atoms bond to four other carbon atoms, and these bonds are covalent, according to the textbook. According to the textbook, diamonds are incredibly hard and have very low electrical conductivity, due to the diamond’s crystal structure and interatomic covalent bonds. Also, it has a very high thermal conductivity, which is unusual for a material that is not metallic in nature. Furthermore, according to the book, diamonds are optically transparent in both visible and infrared regions of the electromagnetic spectrum, and has the ability to refract light. According to the textbook, graphite’s properties are that it is an excellent lubricant due to its interatomic bonds, and high electrical conductivity. Furthermore, according to the textbook, graphite has the ability to maintain high strength and good chemical stability at relatively high temperatures and in non-oxidizing atmospheres, has high thermal conductivity and high resistance to thermal shock, high absorption of gases, as well as the ability to be machined.

According to the textbook, fullerenes, which is a relatively new polymorphic carbon since it was discovered in 1985, has properties that include spectacular electrical insulation, and it also has high conductive and semi-conductive properties when proper impurities are added, according to the textbook.

6. Discuss micro-electro-mechanical systems (MEMS) and why ceramics play an important role in these systems. (10 points)

Answer: According to the text, the microelectromechanical systems or MEMS for short can be defined as “a large number of miniature mechanical devices that are integrated with electrical elements on a silicon substrate. Mechanical components act as microsensors and microactuators and are in the form of beams, gears, motors, and membranes. In the response to microsensor stimuli, the electrical elements render decisions that direct responses to the microactuator devices.” According to the text, in MEMS, the microsensor gathers environmental information via measurement of the mechanical, chemical, thermal, optical, or magnetic phenomena that is occurring. The microelectronic components in MEMS then process this sensory input and analyze the decisions that direct responses from the microactuator devices. These devices perform such responses as moving, positioning, and pumping, according to the text. According to the text, advanced ceramics are used in MEMS due to their heightened electrical, magnetic, and optical properties, which makes the aforementioned application of MEMS possible.

7. What is the role of Yttria stabilized coating (YSZ) on certain turbine blades? Why does the zirconia have to be stabilized? Give examples of some ceramic materials that are used to make lasers? (10 points)

Answer: According to the Wikipedia.org article on yttria-stabilized zirconia, certain turbine blades are coated with yttria stabilized coating because yttria stabilized coating works as a thermal barrier coating for the turbine blades that are utilized in gas turbines (Wikipedia.org). Meaning, the yttriastabilized coating protects the turbine blades from high temperatures brought about by the gas turbines. Furthermore, according to Wikipedia.org, the zirconia must be stabilized because it improves the ion conductivity of both zirconia and the yttria added to it (Wikipedia.org). This stabilization allows for the yttria-stabilized zirconia to operate at high temperatures, making it an ideal thermal coating (Wikipedia.org). According to Wikipedia.org article on transparent ceramics, lasers are made of polycrystalline transparent ceramics, such as Nd: YAG nanomaterial, Yttria, and alumina (Wikipedia.org).

YSZ is Yttria stabilized zirconia. Zirconia is considered a special refractory ceramic. Therefore it can withstand high temperatures without melting or decomposing. Yttrium oxide can be used as a stabilizer. The mixture of the zirconia stabilized by Yttria makes for a good thermal protecting cover for turbine blades.

Zirconia has to be stabilized for it to be useful. Pure ZrO2 experiences a tetragonal- phase transformation at about 1150 degree C. A relatively large volume change accompanies this transformation. This results in crack formations that make the ware properties of ceramics useless. Therefore by adding Yttria the zirconia is stabilized.

Some ceramics are used to make lasers. When a transparent ceramic is alloyed were the material becomes colored a laser can be formed. If aluminum oxide were to be alloyed with chromium this produces ruby. Ruby is used as an optical cavity in a solid state laser. Some other examples that are used to make lasers are the following host glasses borate silicate, and borate silicate phosphate.

8. What are some of the important properties of sintered ceramics? Explain the powder pressing process? (10 points)

Answer: According to sintered ceramics article on Wikipedia.org, some important properties of sintered ceramics include high levels of both purity and uniformity in starting materials, and the preservation of material purity; no bind contact between separated powder particles; the capability to create materials that have a uniform and controlled porosity; the capability to produce objects that have a distinct shape in a large quantity; and the capability to produce materials that cannot otherwise be created by any other process or type of technology

(Wikipedia.org). According to the textbook, the powder pressing process is a method in which clay and non-clay compositions are fabricated. According to the book, this process begins with a powdered mass containing a small amount of water being compacted into a specific shape by pressure implied. Furthermore, the degree of compaction is of a maximum value while the fraction of void space is of a minimized value via the use of both coarse and fine particles during the compaction process. According to the text, the purpose of the water or binder used is to lubricate the powder particles as they move past each other in the compaction process.

According to the textbook, there are three types of powder pressing procedures: uniaxial, isostatic, and hot pressing, In uniaxial, the powder is compacted in a metal die in one direction; in isostatic, the powder is placed in an envelope and a pressure is applied via a fluid; and lastly, in a hot pressing, the powder pressing and heat treatment are performed at the same time.

9. Explain hydroplastic forming & slip casting in a few sentences and then draw schematics of both the process. (10 points)

Answer: According to the text, hydroplastic forming can be defined as “the molding or shaping of clay-based ceramics that have been made plastic and pliable by the addition of water.”

According to the text, the most common type of hydroplastic forming is extrusion, in which a stiff plastic ceramic mass is forced through a die orifice having the desired cross-sectional geometry, which is very similar to the extrusion process for metals. According to the text, products such as bricks, tiles, pipes, and ceramic blocks are all fabricated by the hydroplastic forming process.

According to the text, slip casting can be defined as “a forming technique used for some ceramic materials. A slip, or suspension of solid particles in water is poured into a porous mold. A solid layer then forms on the inside wall as water is absorbed by the mold, leaving a shell having the shape of a mold.” There are two types of slip casting: drain and solid casting. In solid casting, the entire mold cavity becomes a solid, according to the text. Inversely, in drain casting, when the solid shell reaches a desired thickness, the mold is then inverted, which causes the slip to pour out, according to the text.

10. What are refractrories? Discuss the various types of refractrories. (10 points)

Answer: According to the textbook, a refractory can be defined as “ a metal or ceramic that may be exposed to extremely high temperatures without deteriorating rapidly or without melting.”

Furthermore, according to the text, the properties of refractory ceramics include the ability to withstand high temperatures without decomposing or melting, as well as the ability to remain both unreactive and inert when exposed to severe environments. Also, it should be noted that their ability to provide thermal insulation is impeccable. According to the text, there are several classifications of refractory ceramics: fireclay refractories, silica refractories, basic refractories, and special refractories.

In fireclay refractories, the primary ingredients are high-purity fireclays, and alumina and silicon mixtures, according to the text. It should be noted that the highest temperature fire refractories can reach without becoming a liquid is 1587

0

Celsius respectively. It should be further noted that the addition of more alumina will also increase the maximum service temperature, which will allow the formation of a minute amount of liquid. Furthermore, fireclay bricks are used extensively in the construction of furnaces due to the remarkable ability to confine hot atmospheres, as well as their ability to thermally insulate, according to the text.

In silica refractories, the primary ingredient is silica. According to the text, silica refractories are well known for their load-bearing capacities at high temperatures, which makes silica refractories ideal for the arched roofs of both glass and steel making furnaces, in which temperatures as high as 1650 o

Celsius are achieved. Under such extreme conditions, some small portion will become liquid. However, according to the text, the addition of alumina in silica refractories is detrimental to its ability to withstand high temperatures. Therefore, only a small amount of alumina is added to the silica.

According to the text, basic refractories contain an abundance of periclase or magnesia. In most cases, basic refractories may contain calcium, chromium, and iron compounds. In basic refractories, silica is detrimental to the high temperature performance, according to the text.

Furthermore, basic refractories are very resistant to attack by slags that contain very high concentrations of MgO and CaO, and are commonly used in some steel making open hearth furnaces.

According to the textbook, special refractories are high purity oxide materials, many of which maybe produced with very little porosity. Special refractories include silica, magnesia, alumina, zirconia, beryllia, and mullite. According to the text, other special refractories include carbide compounds, in addition to carbide and graphite. According to the text, silicon carbon can be used for electrical heating elements. It should be noted that the most special refractories are very susceptible to oxidation at temperatures as high as 800 o

Celsius, which makes the application of special refractories extremely limited.

Work Cited

“Cordierite”

Wikipedia.org.

Retrieved November 5, 2012, from: http://en.wikipedia.org/wiki/Cordierite

“Barium Titanate”

Wikipedia.org. Retrieved November 5, 2012, from: http://en.wikipedia.org/wiki/Barium_titanate

“Zirconia” Wikipedia.org. Retrieved November 5, 2012, from: http://en.wikipedia.org/wiki/Zirconia

“Sintering Ceramics”

Wikipedia.org. Retrieved November 5, 2012, from: http://en.wikipedia.org/wiki/Sintering

“Transparent Ceramics”

Wikipedia.org.

Retrieved November 5, 2012, from: http://en.wikipedia.org/wiki/Transparent_ceramics

“Yttria-Stabilized Zirconia”

Wikipedia.org

. Retrieved November 4, 2012, from: http://en.wikipedia.org/wiki/Yttria-stabilized_zirconia

Strauch, Annette. “Physical Properties of Space Shuttle Ceramic Tiles.” eHow.com

. Retrieved

November 3, 2012, from: http://www.ehow.com/info_8030281_physical-space-shuttle-ceramictiles.html

Scanned image of rock salt structure taken from: http://cnx.org/content/m16927/latest/

Scanned image of cesium chloride image taken from: http://www.metafysica.nl/turing/preparation_3dim_3.html

Scanned image of zinc blende taken from: http://www.everyscience.com/Chemistry/Inorganic/Ionic_Solids/b.1297.php

“Manganese Sulfide” Wikipedia.org. Retrieved November 5, 2012, from: http://en.wikipedia.org/wiki/Manganese%28II%29_sulfide