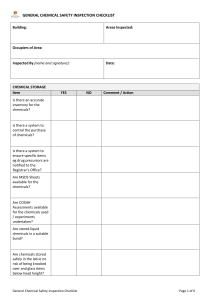

Chemical Safety Inspection Checklist

advertisement

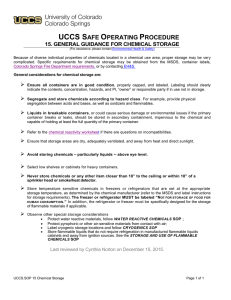

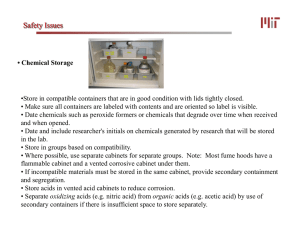

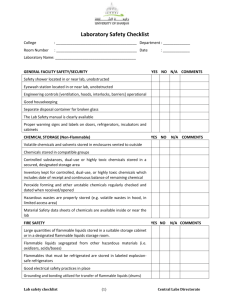

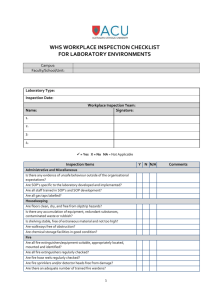

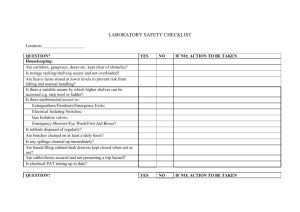

CHEMICAL SAFETY Inspection Checklist Location (Building & Room number): Organisational Unit: Room contact / Responsible person: Inspector / Auditor: Date of Inspection: Physical infrastructure and emergency requirements √/ X Are the signs on external doors adequate to indicate what classes of chemicals are being used and stored? Comments: Do the signs on the entrances to the work area or within the work area reflect the work practices e.g. “eyewear must be worn at all times”? Comments: Is there an emergency 'SHUT DOWN' button at the exit (cuts off the energy to systems i.e. gas, electricity, steam...) Comments: Are spill kits available (with appropriate spill containment material)? Comments: Are fire extinguishers provided and adequate for the chemicals and processes being performed? Comments: Is a safety shower and eye-wash provided? (must have unencumbered access) and are they tested monthly Comments: Is a First Aid Kit available (appropriate to the hazards). Are suitable antidotes available where necessary? Comments: Are all of the fume cupboards tested and in date (check NATA sticker on cupboard, 12 monthly)? Comments: Gas systems, cylinders and cryogenics √/ X Are all gases reticulated (all cylinders and dewars stored outside the lab with hard plumbed, low pressure lines into lab) Comments: Are regulators in good condition, appropriate for type and pressure of gas? Comments: Are all gas cylinders securely restrained Comments: Chemical Safety Inspection Checklist Occupational Health & Safety Unit Page 1 of 2 29 May 2012, v2 Are all gas monitors and oxygen alarms connected to UQ Security? Comments: Volumes of cryogenics have been assessed in relation to room volume and the need for low oxygen alarms? Comments: Chemicals √/ X Is there a Manifest of 'Hazardous Substances' and 'Dangerous Goods' for the lab. Has it been given to the Chemical Store Manager? Comments: Are chemicals storage cabinets labelled with DG class, in good condition, fitted with self closing doors and contain compatible classes of chemicals? Comments: Are Class 3 cabinets located as far as practicable from ignition sources (refrigerators, power points, sparks), class 2.1 and 2.3 gas cylinders, 5.1 and 5.2 cabinets and 6.1 cabinets (>3m if possible)? Comments: Are spark free fridges provided for storage of flammable liquids (If required)? Are all fridges and freezers labelled as to suitability for storage of flammable liquids IE NO FLAMMABLE LIQUIDS IN THIS FRIDGE? Comments: Is the total maximum volume of cabinets < 250 L in a 10 Metre Radius? (based on cabinet label) **Must consider adjoining rooms** Comments: Are risk assessments available for the processes which are using chemicals? Comments: Do staff know how to access material safety data sheets (SDS)? Is access to Chemwatch readily available to all persons? Are SDS’s for high use and high risk chemicals printed out? Comments: Is health surveillance conducted for lead and/or any of the schedule 14 substances listed within the Regulation? Comments: Are chemical containers and contents in good condition and fitted with a legible manufacturers label? Comments: Are decanted containers correctly labelled? Are waste containers appropriately labelled? Comments: Are there any bunding or spill trays for the storage of liquids? Comments: Is the housekeeping satisfactory? Comments: Is there a procedure for chemical waste disposal, consistent with University requirements? Comments: Chemical Safety Inspection Checklist Occupational Health & Safety Unit Page 2 of 2 29 May 2012, v2