Ballot Comments

advertisement

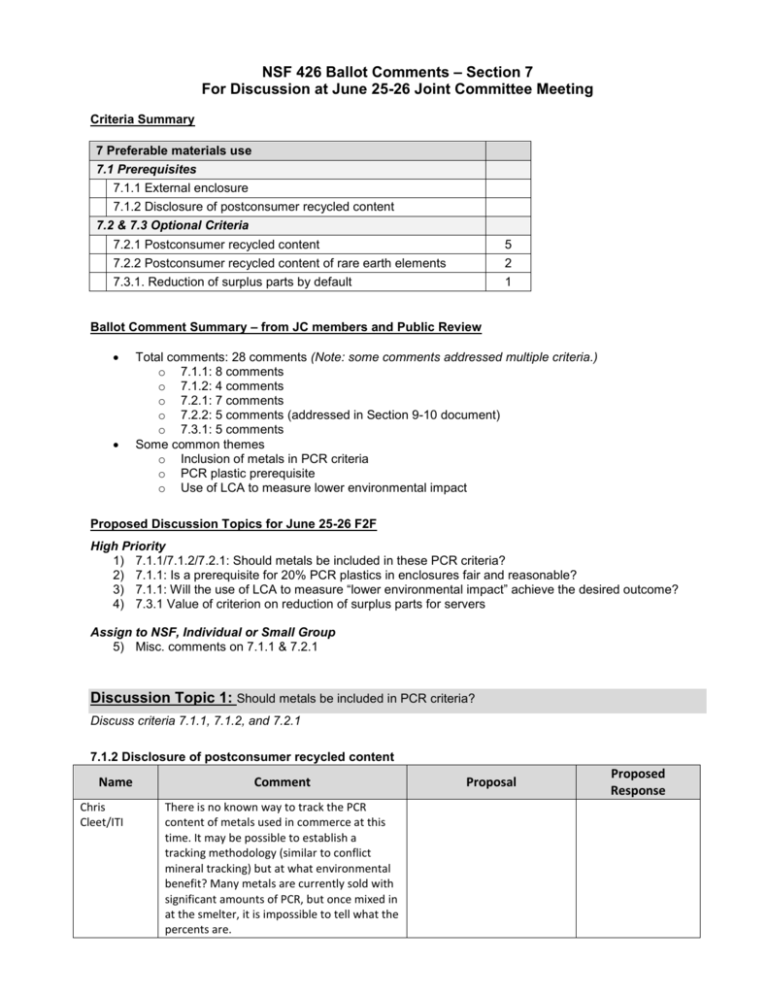

NSF 426 Ballot Comments – Section 7 For Discussion at June 25-26 Joint Committee Meeting Criteria Summary 7 Preferable materials use 7.1 Prerequisites 7.1.1 External enclosure 7.1.2 Disclosure of postconsumer recycled content 7.2 & 7.3 Optional Criteria 7.2.1 Postconsumer recycled content 7.2.2 Postconsumer recycled content of rare earth elements 7.3.1. Reduction of surplus parts by default 5 2 1 Ballot Comment Summary – from JC members and Public Review Total comments: 28 comments (Note: some comments addressed multiple criteria.) o 7.1.1: 8 comments o 7.1.2: 4 comments o 7.2.1: 7 comments o 7.2.2: 5 comments (addressed in Section 9-10 document) o 7.3.1: 5 comments Some common themes o Inclusion of metals in PCR criteria o PCR plastic prerequisite o Use of LCA to measure lower environmental impact Proposed Discussion Topics for June 25-26 F2F High Priority 1) 7.1.1/7.1.2/7.2.1: Should metals be included in these PCR criteria? 2) 7.1.1: Is a prerequisite for 20% PCR plastics in enclosures fair and reasonable? 3) 7.1.1: Will the use of LCA to measure “lower environmental impact” achieve the desired outcome? 4) 7.3.1 Value of criterion on reduction of surplus parts for servers Assign to NSF, Individual or Small Group 5) Misc. comments on 7.1.1 & 7.2.1 Discussion Topic 1: Should metals be included in PCR criteria? Discuss criteria 7.1.1, 7.1.2, and 7.2.1 7.1.2 Disclosure of postconsumer recycled content Name Chris Cleet/ITI Comment There is no known way to track the PCR content of metals used in commerce at this time. It may be possible to establish a tracking methodology (similar to conflict mineral tracking) but at what environmental benefit? Many metals are currently sold with significant amounts of PCR, but once mixed in at the smelter, it is impossible to tell what the percents are. Proposal Proposed Response Tim Mann/IBM We do not support a requirement for reporting on postconsumer recycled content of metals. While it may be possible to determine the PCR content for significant plastic parts, we do not currently have the capability to document recycled content of metals. Developing a system to collect and document the recycled content of metals will be difficult and will have no discernible environmental benefit. 7.2.1 Postconsumer recycled content Name Comment Tim Mann/IBM The vast majority of servers are made up of metals that are already routinely collected and recycled. Specifying increased recycled content in servers will not result in any increased recycling of these metals. Most metal smelters include recycled metals as part of their standard processes; the amount of metal recycled per batch varies. This requirement may be impossible to meet due to smelter batch to batch process decisions and variations. This criterion should not include metal as the infrastructure for recycling metal is substantially in place world-wide; this therefore becomes a point giveaway. I believe that the number of optional points available in 7.2.1, a total of 5, exceeds the environmental benefit to be gained. I believe that 3 optional points is more appropriate. As with 7.1.2, there is currently no way to track PCR content of metals. Server Manufacturer Michael Kirschner/ Design Chain Associates Wayne Rifer/ GEC Chris Cleet/ ITI Proposal Proposed Response Remove the following two lines from table 7.1: • 25% PCR metal • 25% PCR plastic Supply chain availability is also a concern as 25% PCR plastic meeting NEBS flammability rating of UL 94V-0 is not commonly available. Discussion Topic 2: Is a prerequisite for 20% PCR plastics practical, fair and reasonable? Discuss criterion 7.1.1 7.1.1 External enclosure Name Comment Server Manufacturer External enclosures for servers are largely made of steel. It is impractical and of limited environmental benefit to impose a PCR material requirement on the small amount of plastic contained in enclosures. Additionally, any plastic material in the enclosure may have strict performance and/or cosmetic standards that may not be met with PCR content. Proposal Proposed Response Ralph Buoniconti/ SABIC Chris Cleet/ ITI Tim Earl/GBH Richard Krock/Vinyl Institute A minimum percentage of PCR for only one class of materials is unfair. Many discussions during the Joint Committee meetings revolved around the assumption that all steel and aluminum enclosures already have "acceptable" levels of PCR. For steel, this was based upon wide industry averages in the United States only, with no regard given to specific grades of material used in consumer electronics. Plastic manufacturers are able to trace their PCR usage within specific grades, with third-party listing services available. Because metal manufacturers claim this is "too difficult" or maybe "impossible", there is no proof requirement for these metals. Plastics are put at a competitive disadvantage partly because of the very ability of plastic manufacturers to trace PCR. The result is that specific electronic grades of steel and aluminum can be sourced anywhere in the world and are considered "acceptable", no proof required , even if made from 100% virgin aluminum, shipped half way around the world. Meanwhile, a 15% PCR plastic material sourced from a local manufacturing plant either could not be used or would need to undergo an expensive and time consuming LCA. It is not clear that 20% postconsumer resin is feasible for use in casings; no studies show that the color, safety and structural requirements can be met with 20% PCR. An LCA comparing two materials (for example, biobased and PCR) will depend on the specific environmental impacts being considered. It is not clear how specific environmental benefit will be addressed in this criterion. 7.1.1 Metal receives an advantage here with no recycled content necessary to be considered preferable. This should be changed. The required threshold of 20% postconsumer content for plastic enclosures is arbitrary. No life cycle analysis information or data was presented to show that at this level, there is a positive impact on the environment. Additionally no LCA information was provided that would demonstrate that steel or aluminum enclosures are environmentally preferred over plastics, regardless of the plastics recycle content. No evidence was presented to this subcommittee that assures that the steel or I suggest following the structure of other sustainability standards (such as IEEE 1680.1) that set no minimum PCR requirements, but rather reward materials that can show high levels of PCR. Steve Risotto/ACC aluminum used in these products contains post-consumer materials at these levels. If a 20% post-consumer recycle content for enclosures is determined to be a worthy target with defined reductions in environmental impacts, then all enclosure materials – steel, aluminum, and plastics – should be treated similarly to conform to such a threshold. The provision arbitrarily disadvantages the use of plastics for enclosures. It should be revised to provide optional credit for use of PCR materials rather than as a prerequisite and should include comparable PCR criteria for metals. As the recycling content of metals is not routinely tracked, it may be necessary to establish criteria that are consistent with standard industry practice, at least initially. Provide optional credit for use of PCR materials rather than as a prerequisite. Include comparable PCR criteria for metals. Discussion Topic 3: Will the use of LCA to measure “lower environmental impact” achieve the desired outcome? Discuss criterion 7.1.1 and LCA comment on 7.2.1 7.1.1 External enclosure Name Chris Cleet/ITI Holly Elwood/EPA Comment Proposal An LCA comparing two materials (for example, biobased and PCR) will depend on the specific environmental impacts being considered. It is not clear how specific environmental benefit will be addressed in this criterion. The criterion should reference the term “external enclosure” as defined in 3.20 How to measure “lower environmental impact” How were these three choices determined to be equivalent? How is the LCA supposed to demonstrate “lower environmental impact”? Is that across all impact categories, or a majority? 11.2.1. does not indicate how to judge what is “preferable” from the inventory. Also, 11.2.1 outlines an LCA for the whole product, and this criterion is for a particular material. Maybe put in an Annex what makes a good LCA and then reference this in both criteria. Proposed Response William Hoffman/ULE The last bullet allowing for a material with lower environmental impact seems like a loophole to allow any material. Virgin aluminum is one of the most energy intensive materials that could be used. It would seem that almost any other material will have a lower environmental impact because of the energy use of virgin aluminum. In addition "lower environmental impact" is not defined in 11.2.1 and is, in general, a vague term which can mean different things to different stakeholder groups. If one LCA has lower energy use but another has lower EP which is "lower environmental impact"? The last bullet, "- A material demonstrated to have lower environmental impact than those listed above based on an LCA conducted in accordance with criterion 11.2.1.", should be stricken. 7.2.1 Postconsumer recycled content Name Comment Brian Martin/ Seagate Although this is an optional criterion, use of LCA calculations to demonstrate equivalent or less impacts for alternatives to the PCR/WEEE targets would be preferred. Depending on the manufacturing location, local supply chain logistics, and local material availability, impacts for some materials with lower PCR or WEEE content might be lower overall than for the targeted PCR/WEEE content. Proposal Proposed Response JC questions: 1) Keep metals in criteria 7.1.1, 7.1.2, 7.2.1 and/or remove from 1, 2 or all 3? 2) If metals removed from 7.1.1, should the criterion be: a. Retained as is b. Further modified i. Exempt servers that use mostly metals in enclosure (Server manufacturer comment) ii. Strike last bullet for LCA demonstration (William Hoffman proposal) iii. Further define lower environmental impact and LCA (Elwood comment) b. Deleted 3) For criterion 7.2.1 should an LCA option be added? (Brian Martin comment) Discussion Topic 4: Value of criterion 7.3.1 for servers Name Comment Server Manufacturer This criterion (reduction of surplus parts) may be more suited for a PC standard. This criterion adds cost and no clear environmental benefit for servers where most installations are highly customized and unique. In many cases, servers are sold through third party business partners, and it may not be possible to exclude parts in those shipments. Chris Cleet/ ITI Proposal Proposed Response Tim Earl/ GBH Catherine Ho/ Koi Computers Tim Mann/ IBM 7.3.1 Also, blanks and dummies have significant function in the layout of a server to maintain airflow and cooling. Developing a tracking system for this will be very costly and provide very limited environmental benefits. The option to order the minimum number of fans is problematic. Manufacturers are not likely to over spec fans. If the intent is for buyers to specify fewer fans for a “downgraded” or “low end” server, then the possibility exists that it will be upgraded later and lack sufficient cooling, leading to failure or a fire hazard. (We cannot rely on users considering upgrading the fan if they upgrade the server). For Section 7.3.1, can you confirm that 1 point is given if the manufacturer provides the declaration, or does the product configuration need to be "zero" for all surplus parts to get the 1 point? Additionally, what if the customer requires surplus parts for warranty purposes? We do not support this criterion. While some purchasers may welcome the elimination of cables, mounting hardware, and cosmetic dummies from their products, the majority of customers expect and want these included with product shipments. Eliminating these from shipments as a default would likely cause customer satisfaction issues, and is not practical. Revision options: 1) Retain as is 2) Consider revisions (none suggested) 3) Delete criterion (several commenters) Misc. comments on 7.1.1 & 7.2.1 7.1.2 Disclosure of postconsumer recycled content Name Chris Cleet/ ITI Comment Regarding the sentence “additives and fillers used in material shall be included in the denominator”, this would seem to apply to additives and fillers contained in the recycled plastic (which is not reasonably feasible to measure). Proposal Proposed Response Holly Elwood/ EPA Paul Parkinson/In Win 7.1.2 The text says “entire weight of the product, less exclusions, should be included in the denominator”, but the denominator in the formula says “total material (of the type in the numerator) by weight…”. These are very different. If you follow the formula, it is weight of PCR in plastic divided by all plastic, but if you follow the text it is weight of PCR plastic divided weight of entire product (exclusions). Need to clarify what counts and what doesn’t. Maybe an annex with more detail about how to calculate PCR? It was discussed in the development of this criteria that cables cannot be manufactured using recycled plastic and achieve a safety approval from UL specifically and others by assumption. This distorts the calculation as cables must be used as part of the denominator but there is no chance of them being part of the numerator. Clarify that the criterion applies to all materials. Fix the formula and description. Actually, look to next criterion for better details, though it has issues as well. It is suggested that like the printed circuit boards, cables should be added to the parts that are excluded from the calculation. Revision options: Consider revisions a. Exempt cables (Paul Parkinson comment) b. Clarify to address Cleet and Elwood comments 7.2.1 Postconsumer recycled content Tim Earl/ From the table: “Demonstrated GBH conformity with a material traceability standard.” One example given. Either define this in more detail or remove it. Chris Cleet/ ITI 7.2.1 The two traceability standards listed apply to plastics molders. It is not clear who needs to demonstrate conformity and/or how server manufacturers would or should demonstrate conformity. Revision options: Consider revision a. Clarify who needs to demonstrate conformity (Chris Cleet comment) Examples of material traceability standards are provided in footnote.