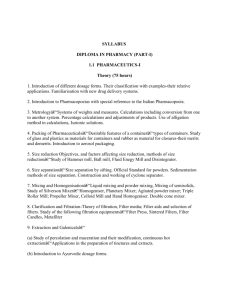

syllabus-Pharamceutics-II

advertisement

Syllabus NIRMA UNIVERSITY INSTITUTE OF PHARMACY B. PHARM SEM III COURSE NAME: PHARMACEUTICS - II (UNIT OPERATIONS - II) Learning Outcomes Upon completion of the course, learner would be able to understand the theoretical concepts and principles used in unit operations and process and correlate them with various practical applications in pharmaceutical industries in the process of formulations of various pharmaceutical products like tablets, capsule, and other liquid preparations etc. Learner will able to justify the selection of proper instrument used for development of desired product by having hands on and knowing construction, working, application, merits and demerits of various instruments. Learner will able to know industrial hazards, and safety precaution measures for it and get familiar with working of pharmaceutical industry by understanding automated process control systems. Theory 1. 2. 3. 4 5 6. L P C 3 3 5 Evaporation Basic concept of phase equilibria, factors affecting evaporation, heat transfer in evaporators, Duhring’s Rule and Raoult’s law, evaporators, natural circulation, forced circulation & film evaporators, single effect and multiple effect evaporators, mathematical problems Distillation Physical concepts, vapour liquid equilibrium relationship, volatility & relative volatility, simple steam and flash distillations, batch and continuous distillation, rectification distillation coloumns and their efficiency, McCabe thiele method for calculations of number of theoretical plates, azeotropic, molecular & steam distillation, mathematical problems Size Reduction Objectives and theory of size reduction, factors influencing size reduction, energy aspects in size reduction, study of various mills including ball mill, hammer mill, fluid energy mill etc., study of latest industrial mills used in manufacturing of various dosage forms, their applications, numerical problems. Size Separation Principles of size separation, screen and its standards as per pharmacopoeia, screening equipments including shaking & vibrating screens, gyratory screens, sedimentation type industrial separators etc. Mixing Theory of mixing, mixing mechanisms, solid – solid, solid – liquid and liquid – liquid mixing equipments. Study of latest mixers used in manufacturing of solid, liquid and semisolid dosage forms in industry, applications in Pharmacy. Crystallization Formation of crystals, super saturation theory, factors affecting crystallization process,. Study of various types of crystallizers. Problem in crystallization process, methods for prevention of caking of crystals, crystal growth. Co-crystals. Advance in crystal technology with respect to API and excipients, Spherical crystallization. Numerical problems on yields, a brief study of spherical 7. 1. 2. 3 4 5 6 7 8 9 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. crystallization process. Leaching and Extraction Principle, theory, types of extraction, solvents used for extraction, leaching and extraction equipments, small scale and large scale extraction methods, special extraction techniques, application in pharmaceutical industry. Total Lectures 45 Practicals To study Material balance in evaporation To study Rectification and steam distillation To Study of Mier’s super solubility curve for given substances To Determine particle size distribution for a given sample using Stoke’s law, sieving method, microscopic method To Perform liquid-liquid extraction, study of percolation method, break through capacity of cationic exchange resin etc. To Demonstrate spherical crystallization process,planetary mixer, ball mill, colloid mill, industrial crystalizer etc. To study mixing efficiency in solid-solid mixer and liquid-liquid mixer To study power requirement for given mill Other practicals related with theory section. Total hours 45 Books Recommended Tutorial Pharmacy by Cooper & Gunn, ed. S.J.Carter, CBS Publishers & Distributors, Delhi. Unit Operations of Chemical Engineering, by McCabe, Smith & Harriott, McGraw – Hill Inc., New York. Gennaro, Alfonso R., Remington: The Science and Practice of Pharmacy, Vol-I & II, Lippincott Williams & Wilkins, New York. Pharmaceutics : The Science of Dosage Form Design - M.E. Aulton. The Theory & Practice of Industrial Pharmacy – Lachman L., Lieberman H.A. & Kanjig J.L, Varghese Publishing House, Bombay. Rawlins, E. A., Bently’s Text Book of Pharmaceutics, 8th edition, Bailliere Tindall, London, All India Traveller Book Seller, New Delhi, 2002 Perry, Robert H., Green, Don W., Maloney, James O., Perry’s Chemical Engineering ‘s Handbook, McGrawHill, Inc., New York, 1998 Alfonso G. Remington: The Science & Practice of Pharmacy. Vol.I & II, Lippincott, Williams & Wilkins Philadelphia. Florence, A. T. Atwood, D. (Eds.) Physicochemical Principles of Pharmacy, Macmillan Press Ltd., London. Ansel, Howard. C., Allen, Loyd V., Popovich, Nicholas G. Pharmaceutical Dosage Forms and Drug Delivery Systems, Lippincott Williams & Wilkins, New York. Aulton, Michael E., Pharmaceutics: The Science of Dosage Form Design, Chrchill Livingstone, London. Introduction to Chemical Engineering by Walter L. Badger & Julius T. Banchero, Mcgraw Hill International edition, New Delhi. Hicky, Anthony, J., Ganderton David., Pharmaceutical Process Engineering ,.Marcel Dekker, Inc., New York , 2001