Project description, TMMI37, spring 2010

advertisement

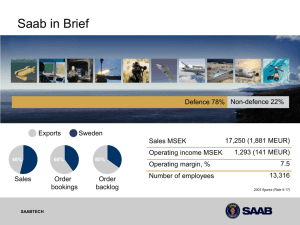

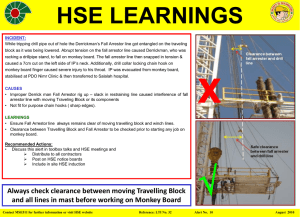

Project description, TMMI37, spring 2014 2014-04-30 Project description, TMMI37, vt2 2014 The aim of this project, which constitutes a mandatory examination task in the course TMMI37 (spring 2014), is that you will have the opportunity to apply the knowledge and skills gained in the course on concrete engineering problems; this year set up in collaboration with SAAB, Linköping, which is a world leading producer of products, services and solutions ranging from military defence to civil security. In detail you are to Part I) Design the nose wheel fork (for the SAAB Gripen/Griffin fighter aircraft) Part II) Evaluate and redesign the flame arrestor bracket (for the SAAB 2000 AEW aircraft) The project contains a mandatory part of the course (Part I), the approval of which is needed for passing the course with grade 3/C, and an optional part (Part II), which is needed for the higher grades (4/B or 5/A, resp.) The project, described on the following pages, is to be reported according to the course information (see also additional remarks below). The oral presentation is to be done in the following way: Firstly, the mandatory project task is to be discussed in groups of approx. 8 people, which are to come up with specific questions/issues of major importance/interest. Secondly, these questions are to be discussed collectively. The discussions are to be led by moderators. Looking forward to meet you and to take part of your results and ideas! Per-Olof Marklund (SAAB) and Kjell Simonsson (LiU) Project description, TMMI37, spring 2014 Part I Design of the nose wheel fork for the SAAB Gripen/Griffin fighter aircraft 2014-04-30 Project description, TMMI37, spring 2014 2014-04-30 Background Above, the principal design of the nose wheel attachment on the SAAB Gripen/Griffin aircraft can be found, with the arrow indicating the direction of flight. The external forces acting on the design are illustrated below. where D=Drag, attaining a large positive value (spin-up) at the moment of ground contact (when the landing device is in its fully un-compressed position), and some hundreds of a second later attaining an approximately equally large negative value (spring-back). B=Brake V=Vertical S=Side, which attains a large value under turning operations or when different brake forces are applied on the two main wheels After landing the spring and damper have been compressed, and the fork is in a horizontal position, see below. The loading is at that time Load case 1: V=60kN, S=B=D=0 On the other hand, when the aircraft is subjected to unsymmetric forces from the brakes, there also exists a side force S. The loading is for this case given by Load case 2: V=25kN, S=10 kN, B=D=0 The three shafts supporting the fork can be treated as completely rigid, and the associated bearings can be treated as frictionless. The dimensions that are found from general requirements and demands on the design is also shown below, where the radius of the tire is r=200 mm. Project description, TMMI37, spring 2014 2014-04-30 Project description, TMMI37, spring 2014 2014-04-30 Material data The fork is to be made of aluminum 7075-t73, with the following data yield stress Rp0.2=395 MPa failure stress Rm=475 MPa density ρ=2.7 kg/dm3. Task The task is to find an as light nose wheel fork design as possible under the given design constraints (see below). If all other mandatory parts of the course have been passed successfully, the approval of Part I of the project will give the grade 3/C on the course. Loading and design constraints With respect to the maximum stressing of the material, the equivalent stress according to von Mises is not to exceed the yield stress (no safety factor needs to be considered in this task). The shafts and the bearings do not need to be modeled, and the loading and constraints can be applied directly on lines or surfaces of the fork. Concerning the load definition, the side force is to be applied on only one of the fork legs (is chosen such that the worst load case is found). However, it is important to note that it also has a moment contribution that is taken up by both fork legs. Project description, TMMI37, spring 2014 2014-04-30 Part II Evaluation and redesign of the flame arrestor bracket for the SAAB 2000 AEW aircraft Project description, TMMI37, spring 2014 2014-04-30 Background The flame arrestor under study, is part of the ventilation system for the fuel tanks in the pressurized zone of the SAAB 2000 AEW (Airborne Early Warning) aircraft (see Figure 1 below). Figure 1: Saab 2000 AEW Aircraft Extra fuel tanks Figure 2: Internal layout of the aircraft The purpose of the flame arrestor is to prevent accidents due to ignition of the fuel. A flame arrestor functions by forcing a flame front through channels too narrow to permit the continuance of a flame. In this project the focus will be placed on its attachment to the fuselage, i.e. on the bracket connecting it to one of the fuselage frames, see the picture on the front page of this description. More specifically the stress state in the current design and the possibility for redesign (see below) is to be investigated. Project description, TMMI37, spring 2014 2014-04-30 Flame arrestor 9309781-006 9309781-010 7528120-014 Hydraflow couplings Fwd Tank 9309781-010 Fixed to structure Aft Tank 7528120-521 9309781-006 Hydraflow couplings Project description, TMMI37, spring 2014 2014-04-30 Tasks The specific tasks of the project are to 1. evaluate the stress state at the bend of the bracket, and to investigate, based on given material properties, design criteria (plastic yielding) and safety factors, the possibility of a redesign towards a lighter part. Here the basic design idea is to be left unchanged, i.e. only dimensions are to be changed. If all other mandatory parts of the course have been passed successfully, the approval of Task 1 of Part II will give the grade 4/B on the course. 2. set up a three-bolt redesign, where also the issue of an increased bolt loading will have to be addressed (at least qualitatively). Here the basic design is to be modified if possible, e.g. parts of the bracket which are not needed can be “cut away”. If all mandatory parts of the course have been passed successfully as well as Task 1 of Part II, the approval of Task 2 of Part II will give the grade 5/A on the course. Even though the CAD-geometry is available for the bracket, you are to create it by yourselves, based on specifications/drawings provided by SAAB (see below), since this will facilitate the redesign work. Specifications and drawings Specifications and drawings regarding geometry, material data and safety factors can be found below Project description, TMMI37, spring 2014 2014-04-30 Project description, TMMI37, spring 2014 2014-04-30 Project description, TMMI37, spring 2014 2014-04-30 Loading and design constraints The basic load case to consider is the one steaming from the inner pressure of the pipe connecting the flame arrestor to the fuel tank. Since the pressure strives to straighten the bent pipe, it will cause a loading on the flame arrestor, which in turn will be taken up by the bracket. When considering the load transfer, it will for the current project be assumed sufficient to just model the bracket, and to apply the loading to the near regions of the bolt holes in a way consistent with the actual loading situation. The loading will be provided by specifications/drawings from SAAB. The size and direction of the load, as well as the application point is shown in Figure 3. 9309781-006 FR1 R1 FP1 FP1 R1 FR1 7528120-521 83mm y x z F=520N (Ultimate load) (x,y,z) = (0,0,0) (x,y,z)=(-232, 891, 436) (x,y,z) = (0,0,0) Figure 3:Load application Project description, TMMI37, spring 2014 2014-04-30 General comments (for both Part I and Part II) The work you have done is to be orally presented and reported (in written form) according to the dates and deadlines found in the course information. In your report you are to present your results, conclusions and suggestions for future work. Note specifically that you in your work are to Use refined meshes for resolving the stress state in highly stressed and critical regions. The meshes used are not allowed to include too distorted elements (important to check this when making mesh refinements). Locally, e.g. at points associated with a loading or a locking/constraint, very high stresses will arise. However, these stresses may be forseen/disregarded. Do not use boundary conditions that you don’t know exactly how they work/act (can of course be studied by using the “help”facilities of the program) Note specifically that you in your report are to Specify and discuss all thoughts, ideas, assumptions, simplifications, approaches, and suggestions for further work. Both the conceptual work and the detailed FE-analyses shall as far as possible be motivated and checked by hand calculations (e.g. by beam theory). Specify all applied loads and boundary conditions used (type and location). Motivate the choice of applied lockings and constraints if these are not obvious, and discuss how another choice might have changed the results (this can of course be tested directly in the program). Specify the element type used Show used element meshes (the original one as well as all refined dittos, and from different perspectives if needed) From the reports it must be clear how the new designs will look (all dimensions must be included in one way or another), but no standardized drawing rules need to be followed. Also state the weight of your designs. Part I and Part II are to be reported separately. Please note that your reports will be made available to SAAB. Project description, TMMI37, spring 2014 2014-04-30 It is extremely important that your report is well structured with respect to its content, and that the written language (Swedish or English) is of a high quality. Detailed instructions of how to write your report will be made available to you.