SREEJESH PILLAI Clavaravila veedu,Sreevalsam , Phone:+918157821484

advertisement

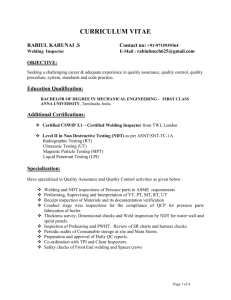

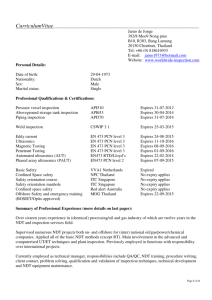

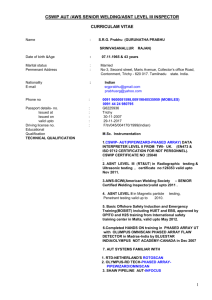

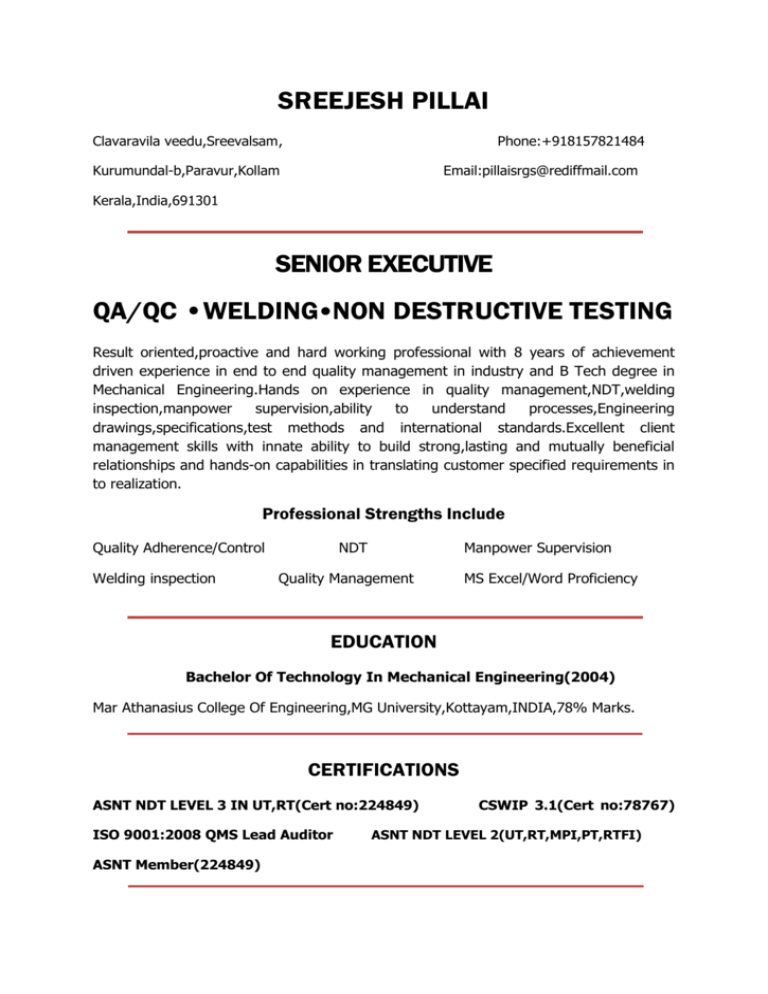

SREEJESH PILLAI Clavaravila veedu,Sreevalsam , Phone:+918157821484 Kurumundal-b,Paravur,Kollam Email:pillaisrgs@rediffmail.com Kerala,India,691301 SENIOR EXECUTIVE QA/QC •WELDING•NON DESTRUCTIVE TESTING Result oriented,proactive and hard working professional with 8 years of achievement driven experience in end to end quality management in industry and B Tech degree in Mechanical Engineering.Hands on experience in quality management,NDT,welding inspection,manpower supervision,ability to understand processes,Engineering drawings,specifications,test methods and international standards.Excellent client management skills with innate ability to build strong,lasting and mutually beneficial relationships and hands-on capabilities in translating customer specified requirements in to realization. Professional Strengths Include Quality Adherence/Control Welding inspection NDT Manpower Supervision Quality Management MS Excel/Word Proficiency EDUCATION Bachelor Of Technology In Mechanical Engineering(2004) Mar Athanasius College Of Engineering,MG University,Kottayam,INDIA,78% Marks. CERTIFICATIONS ASNT NDT LEVEL 3 IN UT,RT(Cert no:224849) ISO 9001:2008 QMS Lead Auditor ASNT Member(224849) CSWIP 3.1(Cert no:78767) ASNT NDT LEVEL 2(UT,RT,MPI,PT,RTFI) PROFESSIONAL EXPERIENCE DYNAMAC ENGINEERING SHIPYARD,SINGAPORE March 2011-Present FPSO/FSO MODULE CONSTRUCTION PROJECTS WELDING INSPECTOR/NDT COORDINATOR Piping/structure Team size: 50 Control Welding process and all related variable parameter (Voltage, ampere, travel speed, etc) Approve UT,RT procedures and execution. Attend Pre inspection meeting with the client representative. Prepare WPS/PQR and sent to the client for approval. Check the Compliance Of all variables stated on the approved welding procedure. Carry out visual inspection of welded joints (including dimensional report). Radiographic film Interpretation of butt welded joints of Category D and normal fluid lines as per ASME B 31.3. Identify repairs from assessment of Visual & NDT reports. Monitor PWHT and verify the reports. Reinspect the weldings with NDT after PWHT. Approval and execution of Excavation procedures of welding repairs. Prepare preliminary WPS and qualify the welders(6G position). Allocation of NDT inspectors as per the project needs. SHARJAH STEEL PIPE MFG COMPANY,UAE 2008-2011 QA/QC Engineer Team size:25 •Establish welding procedure and welding personnel performance qualification . •Supervise in conducting visual and dimensional inspection, destructive test, mechanical testing(yield, tensile and elongation, hardness, charpy impact, drop weight and nick break) for weld and base metal from material receipt to production line and finished product. •Monitor visual and NDT,review specifications of customer enquiry including the regulatory and statutory requirements. •Review daily inspection reports like hydrostatic test, NDT(UT,RT,MPI,PT) ,coating inspection, delivery inspection. •Responsible to plan, conduct , control internal quality audits ,submit reports coordinate with ABS external auditor during surveillance audits. •Radiographic film interpretation of SAW pipes. and GAMA ALMOUSHEGA ARABIA LTD, Saudi Arabia 2007-2008 Welding Inspector Piping •Fit up examination and releasing the assembly joints for welding. •Conducting weld visual examination(TIG,SMAW) and reporting to Quality Manager. •Prepare positive material identification reports, Non-conformance report,WPS/PQR,punch list for hydro testing and witness of dye penetrant test. •Conducting welder performance qualification . •Final welding inspection: Checking welding summary reports, weld map and quality records(NDT,PMI and repair) DASH INSPECTORATE, India 2005-2007 Work Locations: Reliance refinery, IOCL Refinery, Welspun ,PSL Holdings. Third Party QC Inspector(welding/ndt) •Review Of WPS/PQR •Witness of heat treatment,hydrotesting,Automatic UT,Manual UT,MPI,Cold expansion. •Final visual and dimensional inspection. •Inspection of DBT,WBT,RH,Litmus test,Coating temperature, Epoxy thickness,Adhesive thickness,Poly-ethelene thickness, witness of salt test, peel test, holiday test.