Responsible for plant quality engineering

advertisement

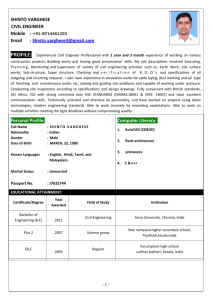

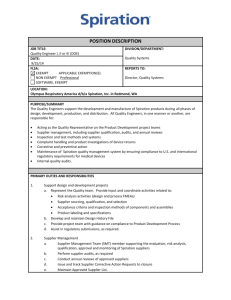

Position Title: Department: Reports To: Quality Engineer Quality Assurance Manager, Quality Assurance 14651 N. Dallas Pkwy, Ste. 500 Dallas, Texas 75254 Summary: Responsible for plant quality engineering including inspection and test documentation, coordination of customer or QMS required documents, recommends revision of specifications, assists in formulating quality assurance policies and procedures, completes corrective action requests, participates in plant quality improvement initiatives. Interfaces with other technical groups within the company and with customers and suppliers on quality related issues. Minimum Qualifications/Experience: 1. Three (3) years quality engineering experience involving highly-engineered industrial capital equipment products. 2. Bachelor’s degree in mechanical engineering, manufacturing engineering, industrial engineering or equivalent (or an Associate’s degree in these fields plus additional 2 years quality engineering experience). 3. Experience with continuous improvement methodologies such as Lean, Six Sigma, and Root Cause Analysis, ISO9001 Quality Management Systems, theory and principles of statistics, advanced quality methods and techniques. 4. Able to use hand held inspection gages, knowledge of CMMs, GD&T, GR&R, inspection and control methods, techniques and documentation. 5. Familiar with AWS D1.1 and ASME BPVC (Boiler & Pressure Vessel Code). 6. Excellent communication skills (written and verbal). 7. Strong computer skills including statistical quality applications, word processing, spreadsheets and databases. 8. Experience with facilitation and team building. 9. Proficiency reading and interpreting complex fabrication drawings and technical specifications. 10. ASQ Certified Quality Engineer preferred. Essential Characteristics: 1. High level of integrity as demonstrated by the ability to consistently conduct him/herself in a proper and professional manner consistent with company policies and to the highest standards of the management staff. 2. Demonstrated ability to effectively set goals and lead others in support of the Company’s strategic vision through analysis, planning, prioritization, communication and problem solving. 3. Outstanding communication skills, both oral and written, with the ability to interface effectively with all levels of the organization. 4. Works in a highly collaborative manner with others to pursue department and company goals. Essential Functions: 1. Prepares customer/authorized inspector inspection notifications, coordinates customer/authorized inspector activities. Page 1 of 3 Quality Engineer 2. Prepares and maintains Receiving, In-Process, and Final Inspection reports, including associated material test reports, supplier certificates of conformance, travelers, and inspection releases. 3. Reviews, approves and/or inspects incoming material, in-process and final inspections as needed. 4. Verify and maintain the calibration of instruments and the record keeping thereof. 5. Support reporting and analysis of key quality metrics. Prepares written reports such as corrective action reports, audit reports, inspection reports, nonconforming material reports, deviation requests, etc. 6. Drives continuous improvement efforts for assigned product line and reduce the cost of poor quality. Performs studies to determine root cause, effect and develop corrective actions. 7. Implement tools for improving product quality on new and existing products using Process Flow Diagrams/Process Maps, PFMEA, and Control Plans. 8. For assigned product line ensures all QA policies, procedures, directives and systems are in compliance with company and/or applicable customer specification. 9. Coordinates with Sales, Engineering, Project Management, Contracts and Manufacturing personnel to resolve problems relative to product conformance to designs, specifications, materials, tooling, and production operations affecting quality. 10. Conducts training sessions to keep personnel informed on procedures, methods, use of equipment, tools and quality control techniques. 11. Actively supports the Company’s QA and human resource needs by identifying and fulfilling individual and system level training requirements, to include corresponding records as they relate to operations. Other Functions: 1. Maintains active contact with other departments, which is positive and supportive of that group’s planning and budget objectives; ensures communication with customers, and/or other team members is conducted in a manner that builds trust and leads to efficient and effective problem resolution. 2. Maintains the confidentiality of all information concerning the Company’s operational practices, marketing, engineering, pricing and sales strategies, as well as customer and prospect lists. The list of items to be considered confidential also includes, but is not limited to, information related to the financial operations and performance of the company. 3. Adheres to all safety policies and procedures in accordance with guidelines established by the Company/OSHA; pursues safety initiatives in support of the Company’s vision of “zero accidents”; maintains a clean, safe and orderly environment. 4. Allocates time efficiently and effectively keeping track of critical information, schedules and deadlines. 5. Ensures daily/weekly/monthly reporting, as well as any other general correspondence, is communicated accurately, concisely, and in a form appropriate to the target audience. 6. Understands and complies with all company policies and procedures as well as additional legal regulatory requirements. Environment: Work is performed in an office and shop floor environment and includes regular computer usage. Additional environments include, but are not limited to, meeting with customers and other business contacts both in field location (work sites), customer offices, third party locations, and company facilities; exposure to standard construction, manufacturing and engineering lab conditions. Occasional travel (less than 20%) may be required in support of the position’s responsibilities (valid in-state driver’s license required, and driving record must meet acceptable company standards and be maintained as such in order to operate a vehicle while on company business). Possible overseas travel (up-to-date Passport is required). Must follow all safety requirements carefully. Hazards: May be exposed to extremes of heat and cold as well as unsafe environments; works near moving mechanical parts and electrical equipment; possible exposure to fumes or airborne particles; possible Page 2 of 3 Quality Engineer exposure to internal liquids. The noise level in the work environment is usually low to moderate and is occasionally very loud. While performing the duties of this job, the employee is regularly required to sit; stand; walk; use hands and fingers to feel and handle; reach with arms and hands; bend; twist; talk and hear. The employee may occasionally be required to stoop, kneel, and crouch. Specific vision abilities required by the job include close vision, distance vision, depth perception and ability to adjust focus. The employee may regularly lift and/or move up to 25 pounds, and may be required to lift and/or move up to 50 pounds on an infrequent basis. Incumbent in this role will be required to maintain a flexible work schedule as some functions may require overtime. Authority: Within the scope of the essential functions of this position, the employee is expected to ensure that quality and safety standards are maintained and that assigned tasks are performed in an efficient and productive manner. Additional: We are a dynamic organization in a rapidly changing industry. Accordingly, the responsibilities associated with this job will change from time to time in accordance with the Company’s business needs. More specifically, the incumbent may be required to perform additional and/or different responsibilities from those set forth above. The above declarations are not intended to be an all-inclusive list of the duties and responsibilities of the job described. Rather, they are intended only to describe the general nature of the job, which is expected to be performed with or without reasonable accommodation. Page 3 of 3 Quality Engineer