notes

advertisement

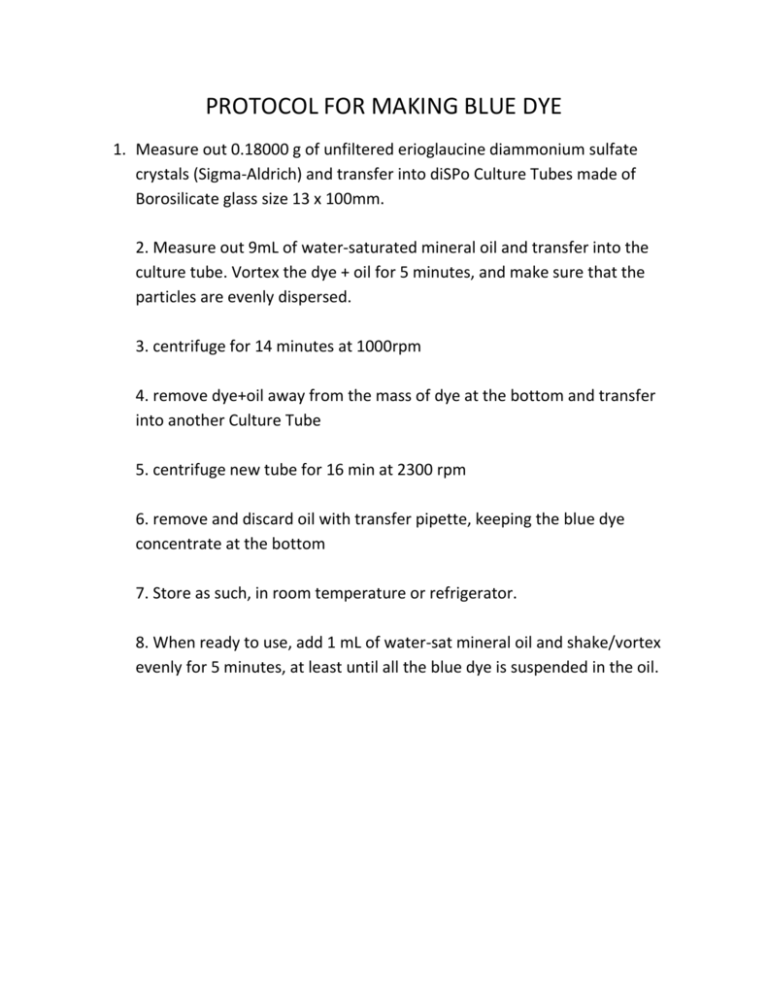

PROTOCOL FOR MAKING BLUE DYE 1. Measure out 0.18000 g of unfiltered erioglaucine diammonium sulfate crystals (Sigma-Aldrich) and transfer into diSPo Culture Tubes made of Borosilicate glass size 13 x 100mm. 2. Measure out 9mL of water-saturated mineral oil and transfer into the culture tube. Vortex the dye + oil for 5 minutes, and make sure that the particles are evenly dispersed. 3. centrifuge for 14 minutes at 1000rpm 4. remove dye+oil away from the mass of dye at the bottom and transfer into another Culture Tube 5. centrifuge new tube for 16 min at 2300 rpm 6. remove and discard oil with transfer pipette, keeping the blue dye concentrate at the bottom 7. Store as such, in room temperature or refrigerator. 8. When ready to use, add 1 mL of water-sat mineral oil and shake/vortex evenly for 5 minutes, at least until all the blue dye is suspended in the oil. PROTOCOL FOR MAKING BLUE DYE v2 1. Measure out ~0.18000 g of unfiltered erioglaucine diammonium sulfate crystals (Sigma-Aldrich) and transfer into diSPo Culture Tubes made of Borosilicate glass size 13 x 100mm (Tube A). 2. Pipette out 9mL of heavy mineral oil and transfer into (Tube A). Because mineral oil slides slowly in pipettes, ensure that all oil is transferred. Vortex the dye + oil for 5 minutes, and make sure that the particles are evenly dispersed in Tube A. 3. Centrifuge (Tube A) for 10 minutes at 1000rpm. Then discard the top 4 mL of mineral oil from Tube A 4. Pipette out the remaining oil of Tube A, while taking care not to disturb the pellet of dye at the bottom. Transfer this oil into a new tube, Tube (B). 5. Centrifuge Tube B for 4 min at 1000 rpm 6. Pipette and discard any remaining oil from Tube B, leaving the new pellet undisturbed. 7. Cap and store, in room temperature or refrigerator. 8. When ready to use, add 1.5 mL of water-saturated heavy mineral oil and shake/vortex evenly for 5 minutes, at least until all the blue dye is suspended in the oil. NOTES: This is highly inefficient, because the discarded dye particle may still be usable. PROTOCOL FOR MAKING BLUE DYE v3 1. Measure out ~0.18000 g of unfiltered erioglaucine diammonium sulfate crystals (Sigma-Aldrich) and transfer into diSPo Culture Tubes made of Borosilicate glass size 13 x 100mm (Tube A). 2. Pipette out 9mL of heavy mineral oil and transfer into Tube A. Because mineral oil slides slowly in pipettes, ensure that all oil is transferred. Vortex the dye + oil for 5 minutes, and make sure that the particles are evenly dispersed in Tube A. 3. Centrifuge (Tube A) for 10 minutes at 1000rpm. Then discard the top 4 mL of mineral oil from Tube A 4. Pipette out the remaining oil of Tube A, while taking care not to disturb the pellet of dye at the bottom. Transfer this oil into a new tube, Tube (B). 5. Centrifuge Tube B for 4 min at 1000 rpm 6. Pipette any remaining oil from Tube B, leaving the new pellet undisturbed, and transfer the oil to a new Tube C. 6a. Centrifuge Tube C for 4 min at 1000 rpm 6b. Discarding remaining oil in Tube C. 7. Cap and store Tube B and C, in room temperature or refrigerator. 8. When ready to use, add 1.5 mL of water-saturated heavy mineral oil and shake/vortex evenly for 5 minutes, at least until all the blue dye is suspended in the oil. NOTES: 12 minutes for Step 3, 4 minutes for Step 5, 4 minutes for Step 6a = bad dye PROTOCOL FOR MAKING BLUE DYE v4 1. Measure out 0.18000 – 0.20000 g of unfiltered erioglaucine diammonium sulfate crystals (Sigma-Aldrich) and transfer into diSPo Culture Tubes made of Borosilicate glass size 13 x 100mm (Tube A). 2. Pipette out 9mL of heavy mineral oil and transfer into Tube A. Because mineral oil slides slowly in pipettes, ensure that all oil is transferred. It may take many tries. Vortex the dye + oil for 5 minutes, and make sure that the particles are evenly dispersed in Tube A. 3. Centrifuge (Tube A) for 10 minutes at 1000rpm. Then discard the top 4 (or 6) mL of mineral oil from Tube A 4. Pipette out the remaining oil of Tube A, while taking care not to disturb the pellet of dye at the bottom. Transfer this oil into a new tube, Tube (B). 5. Vortex Tube B for 3 minutes 6. Divide Tube B into 3 (or 2) divisions of 1.1 mL each (or 1.4, experimental) 6a. Centrifuge each division for 8 min (or 10 min) @ 1000 rpm. 7. Cap and store your 3 (or 2) tubes in room temperature or refrigerator – ensure that there is regular mineral oil during storage or else the dye will dry and harden 8. When ready to use, remove old regular oil, add 1.x mL of water-saturated heavy mineral oil and shake/vortex evenly for 5 minutes, at least until all the blue dye is suspended in the oil. X = the same amount as you pulled out, i.e. 1.1 division = 1.1 oil added NOTES: Still a test in progress (4/3/2009).