Amit Mathur - Rockland Hospital

advertisement

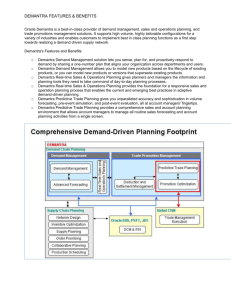

Himanshu Yadav Phone: +91-8888151116 Location: Pune @: himanshu.mailbag@gmail.com MBA in Supply Chain & Operations Management, B. Tech. in Computer Science, with over 3+ years of experience in Supply Chain Management & Analytics. Effective communicator & negotiator with strong analytical, problem solving & organizational abilities. Professional Snapshot Over 4 years of experience in Supply Chain Management and Analytics. Expertise in Forecasting, Demand & Supply Planning, Inventory Optimization, Manufacturing Operations, Project Planning and Scheduling, Process Analytics, Sourcing, Procurement and Fulfilment, Resource Management, MIS using Oracle E-Business suite. Currently associated with Entercoms Solutions Pvt Ltd-Pune as Consultant-Supply Chain Services and role is of a Demand Planner & Supply Chain analyst. Last associated with Varroc Engineering Pvt Ltd - Aurangabad as Assistant Manager-Supply Chain (Procurement) and prior to that as Executive Assistant to President within same organisation. A keen strategist with expertise in managing manufacturing operations with key focus on top line & bottom line profitability by ensuring optimal utilization of resources. Expertise in managing operations involving resource planning, materials planning, in-process inspection, team building and co-ordination with the internal departments. Excellent interpersonal, analytical and negotiation skills with proven track record of utilizing a processoriented approach towards the accomplishment of cost, profit, service & organizational goals. Career Recital September’2011-till date with Entercoms Solutions Pvt Ltd, Pune as Consultant – Supply Chain Services Working as Demand Planner & Supply Chain Analyst (APAC, EMEA, North America region) for ORACLE Corp. Key Result Areas: Optimizing Forecast using Servigistics, Demantra and review forecast against actual shipments for Forecast accuracy (MAPE) and implementing best fit Forecast methodology. Taking action against Under consumed & Over-consumed Forecast for Oracle spares business for APAC, EMEA and US regions. Demand & Supply Planning using Oracle E-Business suite (GSI and VCP) considering Forecast Schedules, Safety stock, Market Intelligence from Marketing & Sales Team, Install Base, and Preventive Maintenance. Been part of UAT team during Demantra, VCP and GSI implementation. Optimizing the inventory by identifying best fit forecast methodology, demand analysis, safety stock management, install base analysis, etc. Constant monitoring of Inventory and maintaining optimal Inventory level to reduce material shortages and increase availability of material for support. Liaising up with Oracle Spares Forecasting Leader, Planning Leader, Sourcing Leader , Manufacturing Leader for availability of Spares at warehouses & for on time delivery to end customers. Forecasting and Budget Controlling by strategic planning. Using Time series methods for calculating forecasts. Identifying key drivers for optimizing forecast accuracy. Supply Execution-Close follow-up with Suppliers, Warehouse & Customers to ensure on time delivery. Ensuring spares planning business metrics such as SORE, NFR, LOA, BO, BO Ageing, New Buy Spend, Inventory turns are met. Daily CSL Misses & Root-Cause analysis and suggestions for improvements pertaining to Forecasting, Planning, Sourcing, Warehousing, and Order Management to meet set CSL Targets. Ensure Oracle spares inventory is well within set targets and analyse root cause for any overshoot & Inventory optimization through planned Material Transfer within Time Zones. Excess Slow & Obsolete reduction & Liquidation. NPI - Information transfer in new product introduction, setting Item Attributes, Seed Stock generation & Inventory Deployment. Communicate verbally and in writing between suppliers, customers and interpret and respond clearly and effectively to spoken requests and written instructions. Creating reports and M.I.S (Weekly CSL analysis report, Inventory Analysis reports, Monthly Metrics, etc.) Tools Used: Oracle E-Business suite R-12 (GSI: Global Single Instance, VCP: Value Chain Processing, Demantra), Servigistics, Soleil, ABR Web. April 2010 - August 2011 with Varroc Engineering Pvt Ltd, Aurangabad Worked as Asst. Manager (Procurement) Key Result Areas: Planning of procurement, production and distribution as per customer schedule. Understand the constraints of Vendors and take corrective measures for adherence to schedule. Doing product evaluation with given specifications and also prepare its Costing. Commercial norms negotiation with vendors. Well versed with taxation and INCO terms. Managing strategic relationships with key suppliers and industry bodies in order to move materials and services flow smoothly and efficiently. Preparing MIS for sales and inventory using SAP. Doing ABC analysis of vendors to decide SOB and New Product Development. Purchase order creation and amendments. Worked as Executive Assistant to President Key Result Areas: Assisting the President with planning and execution of various strategic initiatives. Collect data/information and other input from various plants/ internal/ external sources; building analytics to help the President in taking appropriate business decisions. Planning, implementing & monitoring of technological changes to enhance productivity by finding Bottlenecks, Reducing Cycle Time, etc. Executing cost saving techniques / measures and modifications to achieve substantial reduction in O&M expenditures and work within the budget. Keeping track of various corporate goals/projects led and managed by the President; plot progress and alert if any are on the critical path. Monitoring inventory levels at the various plants, depots and coordinating with purchase department for refilling the same. Generate report on Auto ancillary every month and preparing a weekly summary of all SPD sales against the schedules with analysis. Presenting Weekly/Monthly Production Metrics to management for Operations review. Tools Used: SAP (MM Module) Major Projects Handled Cycle Time Reduction for Improving Productivity from 10k valves/day/line to 14k valves/day/line. Duration: June’11-Oct’11 Team: Handled team of 6 people Description: This project was a Six Sigma Green belt project, first of all critical process chart was made followed by preparation of Process Flow diagram for all the process stages followed by Top Down Chart & Functional Deployment Chart to identify each & every activity / sub activity involved by Conducting qualitative analysis for all activities. Scope of the project was from finding the Bottlenecks and capturing Cycle time for each process. Then we focused on Bottleneck process so as to try and run it at full efficiency and having proper maintenance program so as to reduce breakdown to minimum. And then we also tried to reduce the cycle time by automating some of the processes. Notable Attainments: Awarded in Feb’12 for Root-Cause Analysis on CSL Misses & Forecasting Analysis. Awarded for implementing best strategy for improving NFR which was later implemented by all other planners. Identified various cost saving break-through and implemented the same. Implemented Kanban and FIFO at the assembly line of Integrated Bus Factory at Tata Motors Ltd as part of my summer internship during PGDBM. Project on BENCHMARKING on Internal Supply Chain of DHL. Project on Total Productive Maintenance (TPM) of a motor cycle. Created a Software Requirement Specification (SRS) document for the grading system at ISB&M. Designed software named “DREAM CODER”; user-friendly software based on click events for running SQL queries. Project on “ONLINE RESULT SYSTEM” of ZEDCA using Core Java. Core Competencies Demand Planning, Forecasting & Supply Chain Analytics. Review Forecasts based on Exceptions, Budget Constraints, Outliers. Generate Stocking Policies within setting norms for specific parts. Optimizing the inventory by identifying best fit forecast methodology, demand analysis, safety stock management, install base analysis etc. Identifying areas of improvement and recommending process modifications to enhance operational efficiencies of the system. Preparing Project Plan and Scheduling Activities to ensure timely completion of project without cost overrun. Supplier selection & Negotiation. Process Optimization & Analytics. Installing, optimizing and carrying out improvements through data analysis in the process for new products and existing ones. Carrying out the test runs to identify the parameters, adjustments to be made for stabilising processes. Scholastics PGDBM in Supply Chain & Operations Management from International School of Business & Media (ISB&M)-Pune, in 2008-10. B. Tech. in Computer Science from BBDNITM, Uttar Pradesh Technical University (UPTU) in 20042008. HSC from City Montessori School, Lucknow in year 2004. SSC from City Montessori School, Lucknow, in year 2002. IT Skills Softwares: MS Office (Excel, Word, Power-Point, Visio), Oracle E-Business suite (GSI,VCP, Demantra), SAP, Servigistics, Soleil. Quality Tools and Techniques: ABC Analysis , Six Sigma Methodology, Lean Manufacturing, Kaizen, 5S. Proficiency in programming languages - C, C++, Core Java, VB.Net Personal Dossier Date of Birth: Address: Languages: References: 16th November, 1986 Flat No.504, Celestia Apartments, Balewadi Phata, Baner, Pune English, Hindi, Marathi Available upon request