290715213612Dewoolkar_&_Vaidya_Abstract

advertisement

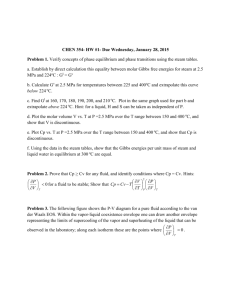

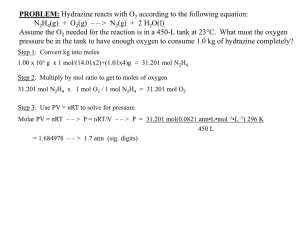

SusChemE 2015 International Conference on Sustainable Chemistry & Engineering October 8-9, 2015, Hotel Lalit, Mumbai __________________________________________________________________________________________ Tailored Hydrotalcite as Hybrid Material for Sorption-Enhanced Reforming of Ethanol Karan D. Dewoolkar, Prakash D. Vaidya Department of Chemical Engineering, Institute of Chemical Technology, N. P. Marg, Matunga, Mumbai-400019 Email: dewoolkarkaran@gmail.com, pd.vaidya@ictmumbai.edu.in ___________________________________________________________________________________________ 1. Introduction: Hydrogen (H2), a potential energy carrier, has several applications in the chemical and energy industries. Sorption-enhanced reforming process (SERP), which combines reaction (steam reforming) and product separation (CO2 adsorption), is a candidate technique for producing pure H2 at temperatures lower than those used in steam reforming [1,2]. In SERP, mixtures of a reforming catalyst and a chemisorbent are employed; alternately, multifunctional hybrid materials which possess the properties of the catalyst and the adsorbent may be used [3]. Such materials are advantageous, due to the fact that they offer low diffusion resistance and improved access to the adsorbent sites. Hydrotalcites, which are layered double hydroxides, represent useful intermediate-temperature sorbents. These materials are durable and easily regenerable; however, they have low adsorption capacity. In the present work, several cationic modified hydrotalcite-based hybrid materials were investigated for SERP using ethanol as feedstock. Ethanol, which can be produced from agricultural products and residues, is a renewable resource for H2; thus, the entire process is very attractive. 2. Materials and Methods: Four hybrid materials, which differed in the cation (Mg, Ca, Cu and Zn) present in the hydrotalcite structure, were synthesized by using co-precipitation technique. Cations, which increase the inter-layer spacing, and hence, the CO2 uptake, were selected for this study. Activity trials for ethanol conversion were performed in a vapour-phase reactor. Product gases were analyzed online using a gas chromatograph (GC) unit equipped with a thermal conductivity detector (TCD). The analysis of the liquid phase was accomplished using flame ionization detector (FID). Further, sorption studies were performed using the hybrid materials. The influence of reaction variables on performance of the investigated materials was studied so: temperature, 573 to 773K, steam/ethanol ratio, 3 to 15 mol/mol, and sorbent mass fraction, 0.085 to 0.25 kg h/mol. 3. Results and Discussion: Ethanol conversion expectedly increased with a rise in temperature, due to the endothermic nature of the reforming reaction (Fig. 1). It was observed that high-purity H2 is produced, even at low reaction temperature. The hybrid material NiCuHTc offered the highest adsorption capacity at 573 K (see Table 1). The product composition was strongly dependent on temperature. Assuming first-order kinetics, it was found that the copper-based hybrid material exhibited the lowest activation energy (44.5 kJ/mol). A reaction pathway for H2 production from ethanol over the selected hybrid materials was suggested. Cyclic stability tests are currently underway. 1 100 XEtOH (mol %) 80 60 NiMgHTc 40 NiCaHTc 20 NiCuHTc NiZnHTc 0 550 600 650 700 Temperature (K) 750 800 Figure 1: Dependence of ethanol conversion on temperature (Reaction pressure = 0.1 MPa, steam/carbon ratio = 9 mol/mol, GHSV = 3600 mL/(g h), time on stream = 3h) Table 1: Dependence of the adsorption capacity on temperature (Reaction pressure = 0.1 MPa, steam/carbon ratio = 9 mol/mol, GHSV = 3600 mL/(g h), time on stream = 3 h). Temperature (K) Qads (mol CO2/ kg sorbent) NiMgHTc (HM1) NiCaHTc (HM2) NiCuHTc (HM3) NiZnHTc (HM4) 0.43 0.09 0.92 0.58 0.31 0.19 0.79 0.7 0.15 0.42 0.74 0.42 0.12 0.53 0.25 0.1 0.06 0.69 0.1 0.04 573 623 673 723 773 4. Conclusions: In the present investigation, a comparative assessment of cation-modified hydrotalcite-based hybrid materials on SERP of ethanol was performed. These hybrid materials resulted in high adsorption capacities and longer breakthrough times at much lower temperatures. Thus, such multifunctional hybrid materials are promising candidates for sustainable and economical H2 production. References [1] Y. Ding, E. Alpay, Chem. Eng. Sci., 55, 2000, 3929-3940. [2] S. G. Mayorga, J. R. Hufton, S. Sircar, T. R. Gaffney, Sorption Enhanced Reaction Process for Production of Hydrogen. Phase I Final Report, DOE/GO/10059-T1, 1997. [3] K. D. Dewoolkar, P. D. Vaidya, Energy Fuels, 29(6) 2015, 3870-3878. 2