2011 Alexandria Annual Report

advertisement

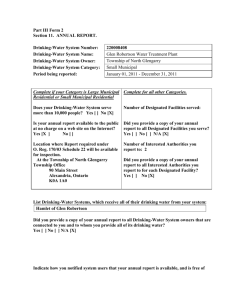

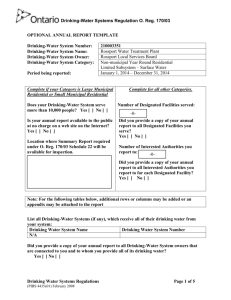

Part III Form 2 Section 11. ANNUAL REPORT. Drinking-Water System Number: Drinking-Water System Name: Drinking-Water System Owner: Drinking-Water System Category: Period being reported: 220001030 Alexandria Water Treatment Plant Township of North Glengarry Large Municipal January 01, 2011- December 31, 2011 Complete if your Category is Large Municipal Residential or Small Municipal Residential Complete for all other Categories. Does your Drinking-Water System serve more than 10,000 people? Yes [ ] No [X] Number of Designated Facilities served: Is your annual report available to the public at no charge on a web site on the Internet? Yes [X] No [ ] Did you provide a copy of your annual report to all Designated Facilities you serve? Yes [ ] No [ ] Location where Report required under O. Reg. 170/03 Schedule 22 will be available for inspection. At the Township of North Glengarry Township Office 90 Main Street Alexandria, Ontario K0A 1A0 Number of Interested Authorities you report to: Did you provide a copy of your annual report to all Interested Authorities you report to for each Designated Facility? Yes [ ] No [X] List Drinking-Water Systems, which receive all of their drinking water from your system: Town of Alexandria Did you provide a copy of your annual report to all Drinking-Water System owners that are connected to you and to whom you provide all of its drinking water? Yes [ ] No [ ] N/A [X] Indicate how you notified system users that your annual report is available, and is free of charge. [X] Public access/notice via the web [X] Public access/notice via Government Office [X] Public access/notice via a newspaper [ ] Public access/notice via Public Request [ ] Public access/notice via a Public Library [ ] Public access/notice via other method _______________________________________ Describe your Drinking-Water System Raw Water Intake Structure Is located in Mill Pond approximately 425 m southwest of the water treatment plant comprising of a vertical 1.5 m diameter, 760 mm high pre-cast concrete pipe placed on a concrete slab housed in a 2.4 by 2.4 m timber crib including screening. Approximately 425 m of 350 mm diameter pipe from the intake crib to the low lift chamber well supplies the water treatment plant with raw water. Low Lift Chamber / Raw Water Well / Low Lift Pumps The chamber is 4.7 by 1.5 by 4.0 m low lift chamber / raw water well located in the southwest corner of the water treatment plant. There are two course screens with an effective opening size of approximately 6.45 m2, raw water well with powdered activated carbon feeding system and low lift pump compartments. The low lift pumps consist of two 14.9 kW vertical turbine low lift pumps located in the low lift chamber / raw water well. Each pump is rated at 6,200 m3/d at 14.6 m total dynamic head (TDH). Each pump is equipped with an automatic flow control valve on the pump discharge restricting flows to the "Permit to Take Water" (PTTW) allowances. Coagulation / Flocculation There are two 2.6 by 4.6 m concrete flocculating chambers operating in series each equipped with a 0.37 kW, 5 rpm agitator. Also included in this process is the coagulant and polymer feeding systems and an in-line mixer. Sedimentation There are four concrete sedimentation tanks with overall internal dimensions of 11.7 by 3.6 by 4.9 m operating in parallel. They are gravity fed by a 0.76 by 16 by 1.3 m conduit line which runs from the flocculation chambers. Each sedimentation tank is baffled with a 4.7 by 2.7 m wall from the inlet and equipped with tube settlers having a cross sectional area of 3.6 by 6.1 m. Each tank also has sludge hoppers and drains discharging to the sanitary system. Filtration The filtration system consists of four concrete 3.9 by 2.9 by 2.8 m filters with a mixed media operating in parallel with each having a surface area of 11.3 m2. Each filter is capable of filtering a maximum flow of approximately 2,003 m2 /d. The filters are complete with surface wash facilities, turbidity meters, loss of head instrumentation and an under drain system. An automatic filter back wash system comprises of two pumps (one duty, one standby), one being rated at 114 L/s, 9.2 m TDH and the other one at 120 L/s, 10.2 m TDH. A supernatant pipe drains to the sanitary sewer system. Disinfection The disinfection system uses chlorine gas which is injected into a header prior to entering the clearwell. The actual chlorination system consists of three chlorinators each having a capacity of 22.7 kg/d equipped with two vacuum regulators and 4 chlorine cylinders. A new chloramination system was commissioned on Dec 20/11 Clear Wells The clear well is divided into two wells (east and west). These two wells have a smaller cell within them and are interconnected by valves. High Lift pumps Three vertical turbine high lift pumps (the No.2 and No.3 as duty/standby, and the No.1 designated to Clearwell located above the clearwell adjacent to the filters, each pump is rated at 75 L/s at 41m TDH, complete with a flow control valve and instrumentation and controls. Emergency power A 175 kW diesel powered generator capable f operating the water treatment plant at full capacity is housed within the Water Treatment Plant. Automated Monitoring and Control An automated control system is capable of monitoring and recording the plant process data such as flows, chlorine residuals and turbidity. The system is also fully alarmed so that should any of the required parameters reach near exceedances, an automatic dialer will notify operators 24 hours a day. A new SCADA system was installed in 2011. List all water treatment chemicals used over this reporting period Powder activated Carbon PAX XL6 CIBA LT27 Polymer Chlorine Gas Potassium Permanganate Env 24P10 phosphate Ammonium Sulphate Were any significant expenses incurred to? [ x ] Install required equipment [ x ] Repair required equipment [ x ] Replace required equipment Describe Install new SCADA to replace existing system. Add chloramination system. Replace all existing pneumatic valves and controls to electrically actuated valves and controls Provide details on the notices submitted in accordance with subsection 18(1) of the Safe Drinking-Water Act or section 16-4 of Schedule 16 of O.Reg.170/03 and reported to Spills Action Center? Incident Date Parameter Result Unit of Measure Corrective Action Corrective Action Date August 31 Oct 24 Total Coliform 1 /100ml Resample Sept 9/11 THM Exceedance 108 Ug/L Flush System Microbiological testing done under section 8 (2) during this reporting period Raw Treated Distribution Number of Samples Range of E.Coli or Fecal Results (#-#) Range of Total Coliform Results (#-#) Number of HPC Samples Range of HPC Results (#-#) 52 52 159 0-198 0-0 0-0 0-2380 0-1 0-0 0 52 >500 0-0 0-2 Operational testing done under Schedule 7, 8 or 9 during the period covered by this Annual Report. Turbidity Chlorine Number of Grab Samples Range of Results (#-#) 165 188 .07-1.40 .07-2.45 Fluoride (If the DWS provides fluoridation) NOTE: Record the unit of measure if it is not milligrams per liter. Summary of additional testing and sampling carried out in accordance with the requirement of an approval or order. Date of order or C of A Parameter Date Sampled Result Unit of Measure Summary of Inorganic parameters tested during this reporting period or most recent Parameter Sample Date Antimony July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th Arsenic Barium Boron Cadmium Chromium Lead Mercury Selenium Result Value < 0.0001 0.0004 0.011 0.017 <0.00002 <0.002 <0.00002 <0.001 Sodium Uranium <.00005 Fluoride Nitrite Nitrate Unit of Measure Exceedance mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L Summary of Organic parameters sampled during this reporting period or most recent Parameter Sample Date Result Value Unit of Measure Alachlor July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th <0.3 <3 <0.02 <0.5 <1 <3 <0.005 <0.3 <3 <1 <0.04 <0.5 <0.5 <1 <5 ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L Aldicarb Aldrin + Dieldrin Atrazine + N-dealkylated metobolites Azinphos-methyl Bendiocarb Benzo(a)pyrene Bromoxynil Carbaryl Carbofuran Chlordane (Total) Chlorpyrifos Cyanazine Diazinon Dicamba Exceedance July 4th July 4th July 4th July 4th <0.1 <0.2 <0.1 <0.1 ug/L ug/L ug/L ug/L July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th July 4th Oct 11th <0.3 ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L July 4th Terbufos July 4th Tetrachloroethylene July 4th 2,3,4,6-Tetrachlorophenol July 4th Triallate July 4th Trichloroethylene July 4th 2,4,6-Trichlorophenol July 4th 2,4,5-Trichlorophenoxy acetic acid (2,4,5-T) July 4th <10 <0.3 1,2-Dichlorobenzene 1,4-Dichlorobenzene 1,2-Dichloroethane 1,1-Dichloroethylene (vinylidene chloride) Dichloromethane 2-4 Dichlorophenol 2,4-Dichlorophenoxy acetic acid (2,4-D) Diclofop-methyl Dimethoate Dinoseb Diquat Diuron Glyphosate Heptachlor + Heptachlor Epoxide Lindane (Total) Malathion Methoxychlor Metolachlor Metribuzin Monochlorobenzene Paraquat Parathion Pentachlorophenol Phorate Picloram Polychlorinated Biphenyls(PCB) Prometryne Simazine THM (NOTE: show latest quarterly average) Temephos <0.1 <5 <1 <0.5 <5 <5 <25 <0.1 <0.1 <5 <0.1 <3 <3 <1 <3 <0.1 <0.3 <5 <0.05 <0.1 <0.5 108.93 ug/L ug/L ug/L ug/L ug/L ug/L ug/L ug/L July 4th Vinyl Chloride <0.2 ug/L List any Inorganic or Organic parameter(s) that exceeded half the standard prescribed in Schedule 2 of Ontario Drinking Water Quality Standards. Parameter Result Value Unit of Measure Date of Sample (Only if category is large municipal residential, small municipal residential, large municipal non residential, small municipal non residential, large non municipal non residential) COMPLIANCE STATUS REPORT SURFACE WATER TREATMENT Municipality: North Glengarry Project: Year: Water Source: Design Cap: Alexandria 2011 Mill Pond 1.24 x 106 Igal/day 5640 m3/day Description: Surface Water Supply with Conventional Water Treatment Flow Effluent Physical/Chem Parameters THM 4 THM quarter Avg. Turb running Avg. Total Flow Avg Day Flow Max Day Flow m3 m3 m3 NTU January 39,344 1,269 2,212 0.21 February 35,252 1,306 1,400 March 41,690 1,489 April 41,306 May Disinfection Avg. Cl2 Res Cl2 Use mg/l mg/l kg 58.54 1.55 130 0.31 1.25 118 1,919 0.24 1.99 166 1,377 1,577 0.20 2.59 105 49,296 1,590 1,965 0.29 1.83 156 June 47,227 1,574 2,024 0.30 1.94 212 July 63,097 2,035 2,635 0.28 1.79 391 August 54,388 1,754 2,648 0.30 2.26 428 September 50,871 1,696 2,218 0.27 1.90 478 October 50,509 1,629 2,582 0.28 1.81 243 November 48,861 1,629 2,173 0.29 1.71 174 December Average Total 52,327 1,688 1586 2,752 0.24 .27 1.40 1.84 182 574168 49.4 40.90 141.5 172.5 56.45 77.85 101.08 2784