Case Study #3

advertisement

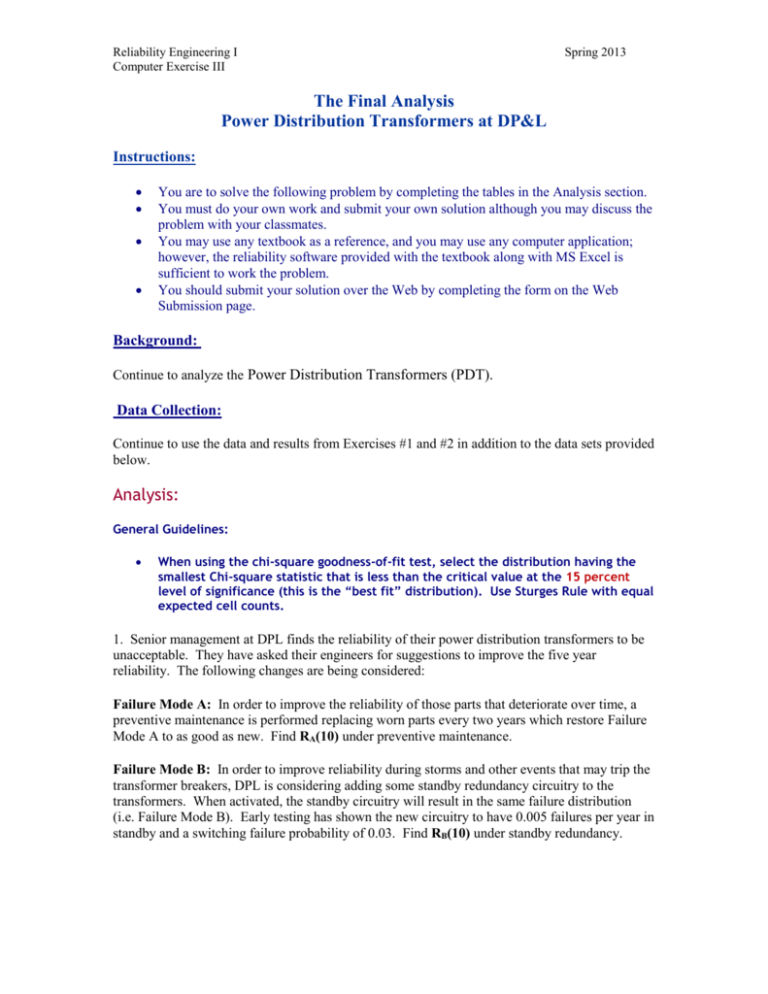

Reliability Engineering I Computer Exercise III Spring 2013 The Final Analysis Power Distribution Transformers at DP&L Instructions: You are to solve the following problem by completing the tables in the Analysis section. You must do your own work and submit your own solution although you may discuss the problem with your classmates. You may use any textbook as a reference, and you may use any computer application; however, the reliability software provided with the textbook along with MS Excel is sufficient to work the problem. You should submit your solution over the Web by completing the form on the Web Submission page. Background: Continue to analyze the Power Distribution Transformers (PDT). Data Collection: Continue to use the data and results from Exercises #1 and #2 in addition to the data sets provided below. Analysis: General Guidelines: When using the chi-square goodness-of-fit test, select the distribution having the smallest Chi-square statistic that is less than the critical value at the 15 percent level of significance (this is the “best fit” distribution). Use Sturges Rule with equal expected cell counts. 1. Senior management at DPL finds the reliability of their power distribution transformers to be unacceptable. They have asked their engineers for suggestions to improve the five year reliability. The following changes are being considered: Failure Mode A: In order to improve the reliability of those parts that deteriorate over time, a preventive maintenance is performed replacing worn parts every two years which restore Failure Mode A to as good as new. Find RA(10) under preventive maintenance. Failure Mode B: In order to improve reliability during storms and other events that may trip the transformer breakers, DPL is considering adding some standby redundancy circuitry to the transformers. When activated, the standby circuitry will result in the same failure distribution (i.e. Failure Mode B). Early testing has shown the new circuitry to have 0.005 failures per year in standby and a switching failure probability of 0.03. Find RB(10) under standby redundancy. Reliability Engineering I Computer Exercise III Spring 2013 Failure Mode C: Many transformers have been plagued with premature failures due to substandard parts. A new parts supplier was found and the failure mode C parts were subjected to accelerated life testing. Forty parts were put on test with the following failure times in years (Type II testing). Based upon a chi-square test, determine the best fit distribution. 0.34 1.14 1.60 8.09 24.64 54.05 67.19 76.23 85.97 88.08 104.94 107.64 121.55 124.22 140.39 149.02 206.48 237.81 241.45 251.12 284.41 317.61 324.90 349.81 422.97 428.32 475.16 507.90 655.45 778.72 Best Fit Distribution MLE Parameter 1 MLE Parameter 2 In order to identify marginal performers and further enhance failure mode C reliability, any new transformer will be operated in a (burn-in) testing environment for one year before being installed in the field. Find RC(10|1) using the fitted distribution with a one year burn-in test period. Complete the following table. Reliability RA(10) Measurement Before the above changes After the above changes RB(10) RC(10) RC(10|1) Rsys(10) 2. In order to analyze the long term frequency of repair at a single BTS, the number of days between failures was recorded as follows: Days Days since since Date of last Date of last Failure Failure Failure Failure 8/1/1998 387 3/2/2005 203 8/23/1999 261 9/21/2005 158 5/10/2000 288 2/26/2006 155 2/22/2001 243 7/31/2006 199 10/23/2001 198 2/15/2007 143 5/9/2002 220 7/8/2007 143 12/15/2002 204 11/28/2007 174 7/7/2003 226 5/20/2008 170 2/18/2004 178 11/6/2008 178 8/14/2004 200 5/3/2009 162 Days between consecutive failures (Type II data) Date of Failure 10/12/2009 3/15/2010 8/14/2010 1/20/2011 5/26/2011 10/11/2011 2/9/2012 6/8/2012 10/24/2012 2/20/2013 Days since last Failure 154 152 159 126 138 121 120 138 119 121 Reliability Engineering I Computer Exercise III Spring 2013 Using the time between failures given in the above data set and assuming a minimal repair process and Type II data, determine if the NHPP power law process is an acceptable model by completing the following table. Unit of time should be in days. Parameter a Parameter b Chi Sq stat for trend test Cramer von Mises test stat for NHPP 3. The replacement cost of a single PDT is $ 2,700 and the cost of a single failure has been estimated at $ 350 which includes maintenance, travel, replacement parts, loss of transmission time, and customer goodwill. Compute the following measures based upon the NHPP power law model obtained in 2 and the repair distribution determined in exercise #2. minimum cost replacement time in years* Probability of no failures the first year Expected number of failures the first 15 years inherent availability over the first 10 (operating) years *assume 365 days a year cost per day at the minimum cost Probability of more than one failure the first year (instantaneous) MTBF in days at the end of the 2nd yr inherent availability over (operating) years 10 -20