Template for Communications for the Journal of the American

advertisement

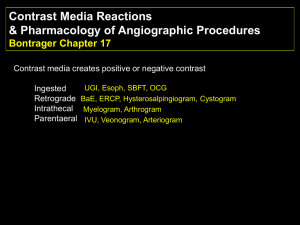

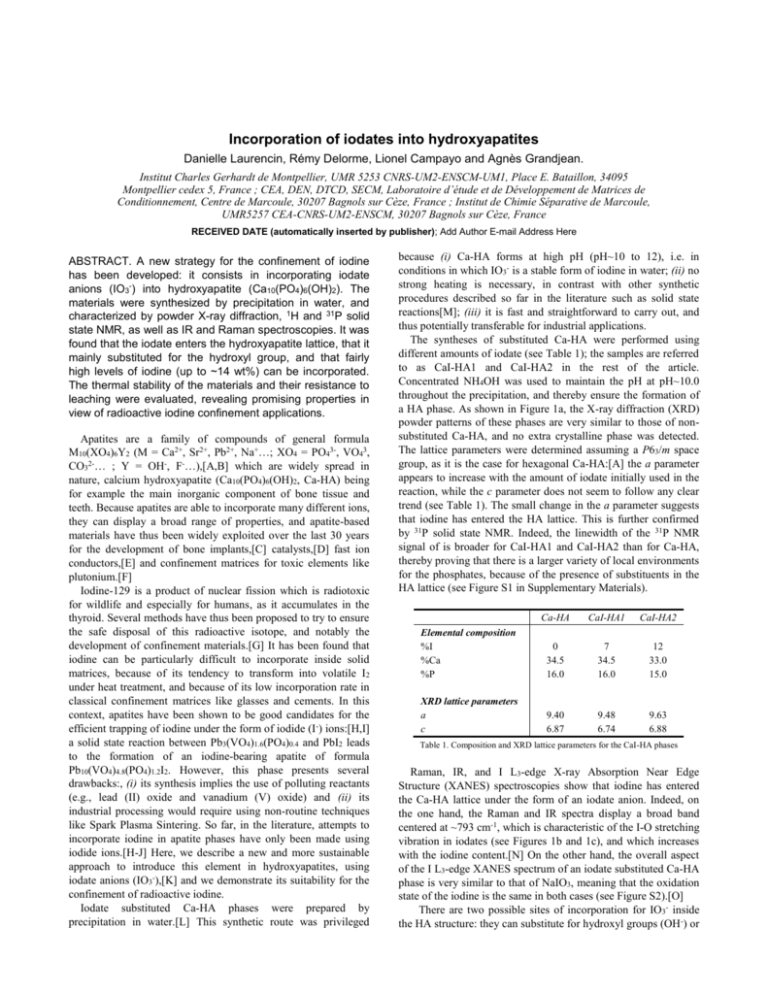

Incorporation of iodates into hydroxyapatites Danielle Laurencin, Rémy Delorme, Lionel Campayo and Agnès Grandjean. Institut Charles Gerhardt de Montpellier, UMR 5253 CNRS-UM2-ENSCM-UM1, Place E. Bataillon, 34095 Montpellier cedex 5, France ; CEA, DEN, DTCD, SECM, Laboratoire d’étude et de Développement de Matrices de Conditionnement, Centre de Marcoule, 30207 Bagnols sur Cèze, France ; Institut de Chimie Séparative de Marcoule, UMR5257 CEA-CNRS-UM2-ENSCM, 30207 Bagnols sur Cèze, France RECEIVED DATE (automatically inserted by publisher); Add Author E-mail Address Here ABSTRACT. A new strategy for the confinement of iodine has been developed: it consists in incorporating iodate anions (IO3-) into hydroxyapatite (Ca10(PO4)6(OH)2). The materials were synthesized by precipitation in water, and characterized by powder X-ray diffraction, 1H and 31P solid state NMR, as well as IR and Raman spectroscopies. It was found that the iodate enters the hydroxyapatite lattice, that it mainly substituted for the hydroxyl group, and that fairly high levels of iodine (up to ~14 wt%) can be incorporated. The thermal stability of the materials and their resistance to leaching were evaluated, revealing promising properties in view of radioactive iodine confinement applications. Apatites are a family of compounds of general formula M10(XO4)6Y2 (M = Ca2+, Sr2+, Pb2+, Na+…; XO4 = PO43-, VO43, CO32-… ; Y = OH-, F-…),[A,B] which are widely spread in nature, calcium hydroxyapatite (Ca10(PO4)6(OH)2, Ca-HA) being for example the main inorganic component of bone tissue and teeth. Because apatites are able to incorporate many different ions, they can display a broad range of properties, and apatite-based materials have thus been widely exploited over the last 30 years for the development of bone implants,[C] catalysts,[D] fast ion conductors,[E] and confinement matrices for toxic elements like plutonium.[F] Iodine-129 is a product of nuclear fission which is radiotoxic for wildlife and especially for humans, as it accumulates in the thyroid. Several methods have thus been proposed to try to ensure the safe disposal of this radioactive isotope, and notably the development of confinement materials.[G] It has been found that iodine can be particularly difficult to incorporate inside solid matrices, because of its tendency to transform into volatile I2 under heat treatment, and because of its low incorporation rate in classical confinement matrices like glasses and cements. In this context, apatites have been shown to be good candidates for the efficient trapping of iodine under the form of iodide (I-) ions:[H,I] a solid state reaction between Pb3(VO4)1.6(PO4)0.4 and PbI2 leads to the formation of an iodine-bearing apatite of formula Pb10(VO4)4.8(PO4)1.2I2. However, this phase presents several drawbacks:, (i) its synthesis implies the use of polluting reactants (e.g., lead (II) oxide and vanadium (V) oxide) and (ii) its industrial processing would require using non-routine techniques like Spark Plasma Sintering. So far, in the literature, attempts to incorporate iodine in apatite phases have only been made using iodide ions.[H-J] Here, we describe a new and more sustainable approach to introduce this element in hydroxyapatites, using iodate anions (IO3-),[K] and we demonstrate its suitability for the confinement of radioactive iodine. Iodate substituted Ca-HA phases were prepared by precipitation in water.[L] This synthetic route was privileged because (i) Ca-HA forms at high pH (pH~10 to 12), i.e. in conditions in which IO3- is a stable form of iodine in water; (ii) no strong heating is necessary, in contrast with other synthetic procedures described so far in the literature such as solid state reactions[M]; (iii) it is fast and straightforward to carry out, and thus potentially transferable for industrial applications. The syntheses of substituted Ca-HA were performed using different amounts of iodate (see Table 1); the samples are referred to as CaI-HA1 and CaI-HA2 in the rest of the article. Concentrated NH4OH was used to maintain the pH at pH~10.0 throughout the precipitation, and thereby ensure the formation of a HA phase. As shown in Figure 1a, the X-ray diffraction (XRD) powder patterns of these phases are very similar to those of nonsubstituted Ca-HA, and no extra crystalline phase was detected. The lattice parameters were determined assuming a P63/m space group, as it is the case for hexagonal Ca-HA:[A] the a parameter appears to increase with the amount of iodate initially used in the reaction, while the c parameter does not seem to follow any clear trend (see Table 1). The small change in the a parameter suggests that iodine has entered the HA lattice. This is further confirmed by 31P solid state NMR. Indeed, the linewidth of the 31P NMR signal of is broader for CaI-HA1 and CaI-HA2 than for Ca-HA, thereby proving that there is a larger variety of local environments for the phosphates, because of the presence of substituents in the HA lattice (see Figure S1 in Supplementary Materials). Ca-HA CaI-HA1 CaI-HA2 Elemental composition %I %Ca %P 0 34.5 16.0 7 34.5 16.0 12 33.0 15.0 XRD lattice parameters a c 9.40 6.87 9.48 6.74 9.63 6.88 Table 1. Composition and XRD lattice parameters for the CaI-HA phases Raman, IR, and I L3-edge X-ray Absorption Near Edge Structure (XANES) spectroscopies show that iodine has entered the Ca-HA lattice under the form of an iodate anion. Indeed, on the one hand, the Raman and IR spectra display a broad band centered at ~793 cm-1, which is characteristic of the I-O stretching vibration in iodates (see Figures 1b and 1c), and which increases with the iodine content.[N] On the other hand, the overall aspect of the I L3-edge XANES spectrum of an iodate substituted Ca-HA phase is very similar to that of NaIO3, meaning that the oxidation state of the iodine is the same in both cases (see Figure S2).[O] There are two possible sites of incorporation for IO3- inside the HA structure: they can substitute for hydroxyl groups (OH-) or a- (I-O) CaI-HA2 CaI-HA2 CaI-HA1 CaI-HA1 Ca-HA Ca-HA 400 20 30 40 50 2Q( ) 60 70 c- 600 800 1000 Raman shift (cm-1) d(I-O) L(O-H) H2O OH CaI-HA2 CaI-HA2 CaI-HA1 Ca-HA CaI-HA1 Ca-HA 1800 1400 1000 σ (cm-1) 600 1.6 1.2 0.8 0.4 0.0 0 5 10 15 time (days) Figure 2. Normalized weight loss of CaI-HA1 in a leach test b- 10 weight loss (10-2 g.m-2) for phosphates (PO43-). In the latter case, different charge balancing schemes can occur, such as the creation of ionic vacancies.[A,B] Both substitution sites can a priori be proposed for the incorporation of iodates, notably because their charge is the same as for the hydroxyls, but their size is more similar to that of phosphates. IR and 1H solid state NMR provide information on the substitution mechanism. Indeed, as shown in Figure 1c, a decrease of the intensity of the O-H IR vibration band at 628 cm-1[M] is observed when the iodate content increases. Similarly, on the 1H NMR spectra (Figure 1d), a decrease in intensity of the OH peak is observed. Thus, it appears that the iodate mainly enters the hydroxyl site. It is noteworthy that the 1H hydroxyl signal is also broader for the iodate substituted HA than for the non-substituted phase, because of the increase of local environments after incorporation of iodates. 12 10 8 6 4 2 0 -2 -4 -6 -8 1H chemical shift (ppm) Figure 1. a/XRD, b/Raman, c/ IR and d/ 1H solid state NMR data of CaI-HA Elemental analyses were carried out to determine the exact composition of the samples (Table 1). It is worth noting that the actual Ca, P and I contents of these substituted HA phases are different compared to what could have been expected from the relative amounts of precursors initially introduced in solution (Table S1). Nevertheless, it appears that the iodine content in CaIHA1 and CaI-HA2 is ~9.9 and 13.1 wt %, which is comparable to that had been obtained previously for Pb10(VO4)4.8(PO4)1.2I2, taking into account the difference in densities. Another big advantage of CaI-HA1 and CaI-HA2, in view of confinement applications, is that apart from the iodates, they are composed of environmentally friendly ions, i.e. calcium and phosphates. For the samples to be potentially used for confinement applications, their stability in temperature and their leaching resistance must be evaluated. Thermo Gravimetric Analyses (TGA) were carried out, showing that the samples remain intact up to ~550°C, temperature at which the iodine progressively starts to react to be released under the form of volatile I2 (see Figure S3). On the other hand, the long-term behavior of CaI-HA1 was evaluated using a simple leaching test, in which the sample is exposed to pure water at 90°C, and the amount of iodine released titrated using an iodine selective electrode (see Supplementary Materials for details). Figure 2 shows the normalized weight loss of the solid during the leaching test. The initial rate of release of iodine from this material is ~10-3 g.m-2.day-1, and it rapidly decreases to ~10-4 g.m-2.day-1 after a few days. This leaching experiment is not normative due to the large specific surface area of CaI-HA1 (92 m².g-1), which leads to a larger S/V ratio than that used for the determination of initial leaching rates in confinement matrices (cf MCC-1 leach test). Nevertheless, the leaching rates measured here are qualitatively comparable to those found in the literature for other iodine-confinement materials. Indeed, dynamic leaching tests performed on phases like Pb10(VO4)4.8(PO4)1.2I2 at 90°C and using pure water, also showed an initial leaching rate ~10-3 g.m-2day-1 on the basis of iodine release.[H] In these results, S/V ratio ranges between 30 and 80 cm-1 by comparison with a value of 460 cm-1 used in this work. These differences could lead to an underestimation of the real initial leaching rate. Although additional experiments on CaI-HA dense pellets would be necessary to fully evaluate their iodine confinement capacity, these preliminary leaching tests appear particularly promising for future applications of these materials. In conclusion, a new method of incorporating iodine in HA has been developed: for the first time, iodate-substituted apatite phases have been synthesized. Their thermal stability up to ~550°C and the slow release rate of the iodate under leaching conditions make them interesting candidates for the confinement of radioactive 129I. Additionally, iodate substituted Ca-HA phases could also find applications in medicine: indeed, studying these phases could help learn more about iodine related diseases like goiter, and could also lead the way to the development of new cures. Acknowledgements. CEA and CNRS for their financial support. We acknowledge the French synchrotron SOLEIL for provision of synchrotron radiation facilities (project 20090572), and Dr Delphine Vantelon for her assistance in the XANES experiments. Supporting Information Available. Experimental details on the synthesis of CaI-HA phases, on the leach test, and on the analytical techniques used to characterize the materials. 31P MAS NMR spectra, I L3 XANES data of CaI-HA. TGA of CaI-HA1. References [A] Elliott, J. C. Studies in inorganic chemistry Volume 18: Structure and chemistry of the apatites and other calcium orthophosphates, Amsterdam: Elsevier, 1994. [B] Pan, Y.; Fleet, M. E. Rev. Miner. Geochem. 2002; 48: 13. [C] Kamitakahara, M.; Ohtsuki, C.; Miyazaki, T., Biomed.l Mater. 2007, 2 R17. [D] Xu, J.; White, T.; Li, P.; He, C.; Han, Y.-F. J. Am. Chem. Soc. 2010, 132, 13172. [E] Tolchard, J. R.; Slater, P. R.; Islam, M. S. Adv. Funct. Mater. 2007, 17, 2564 [F] Vance, E. R.; Ball, C. J.; Begg, B. D.; Carter, M. L.; Day, R. A.; Thorogood, G. J. J. Am. Ceram. Soc. 2003, 86, 1223. [G] a- Chapman, K. W. ; Chupas, P. J. ; Nenoff, T. M. J. Am. Chem. Soc. 2010, 132, 8897. b- Strachan, D. M.; Babad, H. DOE repport under contract EY-77-C-061030 1979. c- Tomita, F.; Wada, M.; Misutsuka, N.; Kaneko, M.; Toyohara, M.; Fujihara, H. Radioactive Waste Management and Environmental Remediation – ASME 1999. [H] Guy C. Audubert F., Lartigue, J. E. C. R. Phys. 2002, 3, 827. [I] Uno, M.; Shinohara, M.; Kurosaki, K.; Yamanaka, S. J. Nucl. Mater. 2001, 294, 119. [J] Henning, P. A.; Lindin, S.; Petricek, V. Acta Cryst B55, 1999, 165. [K] Laurencin, D.; Grandjean, A.; Campayo, L. French patent N°E.N. 10/52216, deposited on 26/03/2010 [L] Bertoni., E.; Bigi, A.; Cojazzi, G.; Gandolfi, M.; Pazavolta, S.; Roveri, N. J. Inorg. Biochem 1998, 72, 29; [M] Fowler B.O., Inorg. Chem. 1974, 13, 207. [N] Pracht, G.: Lutz, H.D. Thermochim Acta 2000, 354, 153. [O] Shimamoto, Y. S.; Takahashi, Y. Analytical Sci. 2008, 24, 405. Table of Contents artwork