How To Treat Odors In Well Water

The incidence of “rotten egg” sulfur odors and black or gray water in hot and

cold water lines are due to the reaction of sulfates and microorganisms in

water. This can occur in the well directly, or in the household plumbing in

both hot and cold water pipes, or in only the water heater and hot water lines.

Cold Water Odor or Hot Water Odor?

To determine the source of the odor and decide on the type of treatment

required, it is important to first check to see whether the cold water contains

odor, or just the hot.

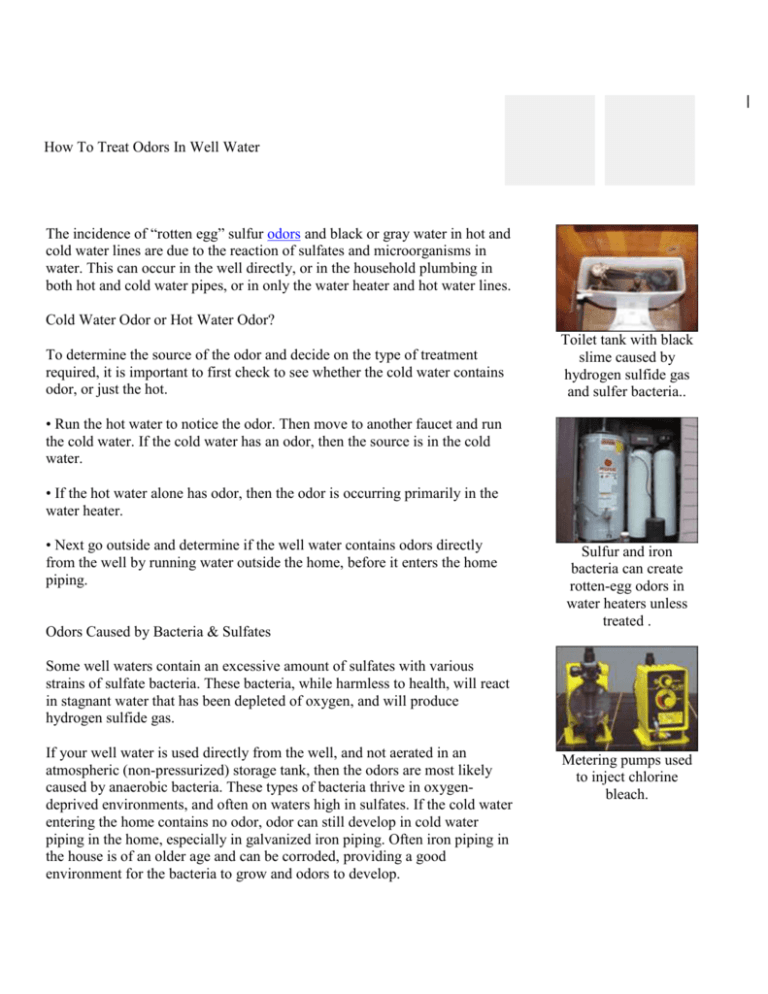

Toilet tank with black

slime caused by

hydrogen sulfide gas

and sulfer bacteria..

• Run the hot water to notice the odor. Then move to another faucet and run

the cold water. If the cold water has an odor, then the source is in the cold

water.

• If the hot water alone has odor, then the odor is occurring primarily in the

water heater.

• Next go outside and determine if the well water contains odors directly

from the well by running water outside the home, before it enters the home

piping.

Odors Caused by Bacteria & Sulfates

Sulfur and iron

bacteria can create

rotten-egg odors in

water heaters unless

treated .

Some well waters contain an excessive amount of sulfates with various

strains of sulfate bacteria. These bacteria, while harmless to health, will react

in stagnant water that has been depleted of oxygen, and will produce

hydrogen sulfide gas.

If your well water is used directly from the well, and not aerated in an

atmospheric (non-pressurized) storage tank, then the odors are most likely

caused by anaerobic bacteria. These types of bacteria thrive in oxygendeprived environments, and often on waters high in sulfates. If the cold water

entering the home contains no odor, odor can still develop in cold water

piping in the home, especially in galvanized iron piping. Often iron piping in

the house is of an older age and can be corroded, providing a good

environment for the bacteria to grow and odors to develop.

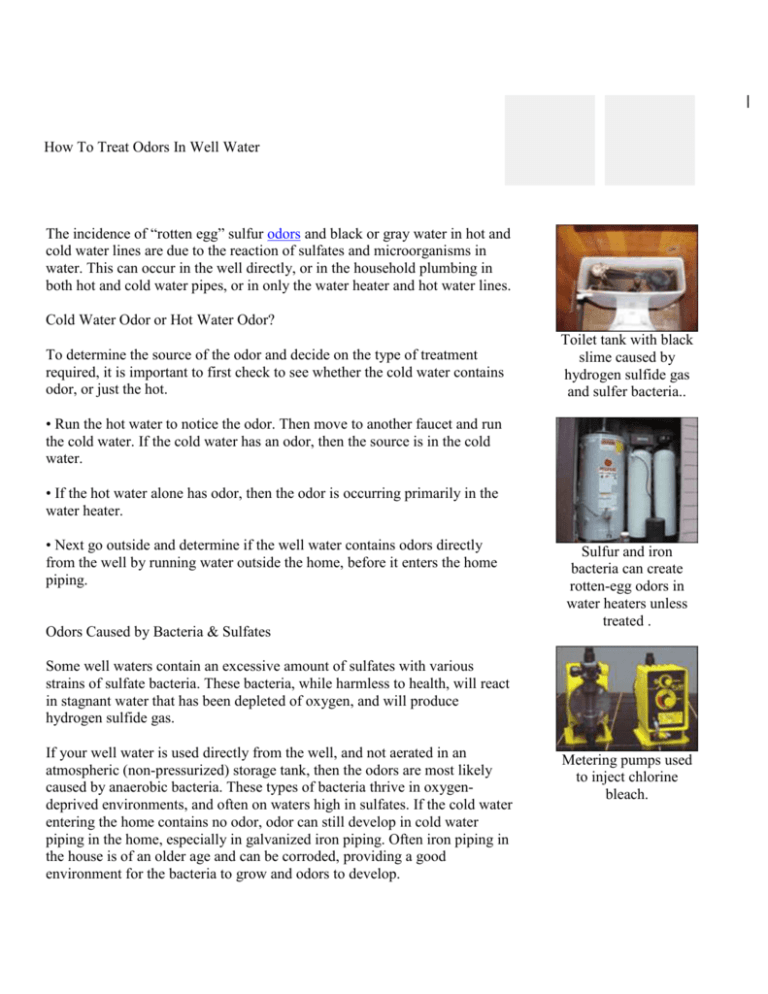

Metering pumps used

to inject chlorine

bleach.

If there is an odor in the cold water inside the home, but not directly from the

well, see if the piping is iron piping, and then replace it with copper. As a

first step to this process, one can shock-chlorinate the piping and sanitize it,

and see if the odor can be eliminated.

Water Heater Odors

If the water is in the hot water only, then a shock-chlorination of the water

heater and servicing or replacing the anode rod in the water heater can

eliminate this problem.

Water heater showing

sacrificial anode rod.

Almost all water heaters have “anode rods” which in a cathode-anode

reaction, produce excess ions that wear off the anode rod and adhere to the

inside glass lining of the water heater, preventing corrosion. These bacteria

(typically the “desulfovibrio” or a related species) can be killed with

adequate amounts of chlorine by periodic shock chlorination, or by

continuous ozone or chlorination, or by turning up the water heater to

extremely high (often dangerous) temperatures.

Odors Present Directly From Well Water (outside house)

One of the following methods is typically used to remove hydrogen sulfide

gas from well water:

• Periodic shock chlorination with high doses of chlorine

• Aeration of the water to oxidize the hydrogen sulfide gas, combined with

periodic shock chlorination.

Greensand filter with

potassium

permanganate alone

removes odors, but

works better with

chlorine feed.

• Chlorine, hydrogen peroxide, or ozone injection alone

• Filtration of the odor by greensand media, activated carbon or other filter

media

• Chlorine, hydrogen peroxide, or ozone injection followed by filtration with

greensand, activated carbon or other media.

Periodic shock chlorination with high doses of chlorine

This involves injecting into the well, pump system and piping a 50 to 200

ppm dose of chlorine. The chlorine residual is allowed to sit in the well for 6

to 24 hours, and then the water is pumped out until the chlorine residual is

gone. This will typically eliminate the odor problem temporarily. If the odor

Ozone generator used

for odor removal from

well water.

returns, often within a couple of days to a few weeks, the procedure can be

repeated. If after a couple of repeated shock-chlorination procedures, the odor

is still present, one of the other methods will need to be used.

Aeration of the water to oxidize the hydrogen sulfide gas, combined with

periodic shock chlorination.

Since the bacteria that create the hydrogen sulfide odor are usually anaerobic,

or bacteria that cannot thrive in oxygen rich environments, often aeration in a

non-pressurized vented holding tank is beneficial to eliminate and drive off

the gas into atmosphere. This works best if the pH is low (less than 7.0) since

the hydrogen sulfide gas at pH higher than 7.0 will not easily gas off

completely.

Continuous Chlorine Injection

Odors can be controlled in water by chlorination, followed by retention or

contact time and aeration. See Fig. 1. Chlorine is a powerful oxidizer, and

while not as powerful as ozone by weight, is less expensive to install and

operate than ozone systems.

Usually 2.0 to 3.0 ppm of chlorine is injected for every 1 ppm of sulfide,

however if the pH is over 7.8 it can take up to 5 to 10 ppm of chlorine per 1

ppm of sulfide to treat hydrogen sulfide. If the pH is over 8.0 we usually

recommend ozone or hydrogen peroxide injection instead of chlorine bleach.

With chorine, as ozone, contact time and concentration of the chlorine is

critical. The chlorine can be injected either in before an open atmospheric

holding tank (Figure 3) or injected under pressure using a metering pump and

a contact tank or pressure tank. Chlorine injection followed by a contact tank

and a good backwash filter system is the more thorough approach.

Fig. 1 Chlorine Injection with non-pressurized tank

Hydrogen Sulfide Test

Kit

Ozone

There are two main methods for injecting ozone into water. In Method 1, (see

Figure 1) an open holding tank of at least a 200-gallon capacity is used.

Larger holding tanks up to 5000 gallons work better. A compressor or blower

is set up on a timer, or wired in so that when the well pump runs, the ozone

blower system runs. The air compressor is hooked up to a ceramic diffuser

stone, creating a large volume of tiny air bubbles.

If sufficient air is used, and the hydrogen sulfide levels are low, this method,

combined with periodic shock chlorination works well. Shock chlorination is

required to keep the levels of bacteria down in the well and holding tank.

In the open bubbler tank design, a UV generated ozone generator can be

used. The UV-generated ozone systems produce lower concentrations of

ozone but lots of aeration is used, and these ozone generators cost a lot less

than corona-discharge generators. Aeration and residence time allow the

hydrogen sulfide gasses to be oxidized and odors eliminated.

In the second method (Figure 2) , ozone is injected via a venturi under

pressure, as the water flows through a contact tank. This type of ozone

injection usually requires higher concentrations of ozone and typically a

corona-discharge generator with dry air or oxygen feed gas is used.

Since there is less residence time and the ozone is under pressure, as the

water is flowing through the contact column. This type of ozone injection

does not require an open holding tank and second booster pump. It does

require an ozone generator capable of putting out a much more concentrated

level of ozone gas, and stainless steel tanks, or ozone-resistant plastic tank

must be used to avoid corrosion problems.

Usually, after either types of ozone injection, in Figure 1 or Figure 2,

filtration is required. Depending on the water chemistry, filtration by

greensand, sand and anthracite, or activated carbon filters are used. These

types of filters are periodically backwashed to keep the media clean and free

of trapped sulfides, iron or manganese oxides.

Fig. 2 Ozone injection and contact tank

Removal of Odors by Filtration

Hydrogen sulfide gas odors can be removed by filtration but results vary, and

usually filtration alone is not effective. The reasons for this are that typically

odors and hydrogen sulfide gas are the result of bacterial action. Often the

odors can be removed at point of entry to the home or business, and then

develop again in the piping system and water heater.

It is more effective to use filtration after aeration, ozone, peroxide or chlorine

injection for best results. In some applications, with low levels of hydrogen

sulfide gas odors, greensand media filters, regenerated with potassium

permanganate are the very effective in removing hydrogen sulfide or rotten

egg odors.

Activated carbon is less effective and the life of activated carbon media beds

are short, and often require frequent replacing, sometimes within a few weeks

after installing the carbon filter.

A very effective and low cost method of hydrogen suflide gas removal is by

injecting chlorine or hydrogen peroxide, followed by a Greensand-Plus filter.

Greensand-Plus is an improved type of greensand filter media that does not

require potassium permanganate. A slight chlorine residual can be left in the

water after the filter, so that the pipes and water heater are kept disinfected,

elmininating any chance for odors redeveloping in the household piping.

Figure 3

Greensand Plus Iron & Odor Filtration System

See Figure 3. The booster pump is controlled by pressure switch. When

pressure in pressure tank drops below the cut-in point on the pressure switch

the booster pump and metering pump turn on. As water is pumped through

the system, a small amount of chlorine or hydrogen peroxide is pumped into

the water by the metering pump.

As the water flows into the contact tank, the chlorine is thoroughly mixed in

the water, allowing contact time to kill any bacteria and oxidize any iron,

manganese or hydrogen sulfide gas. Precipitated oxidized particles of iron,

sulfides and manganese are filtered out of the water by the greensand-plus

media filtration system.

Periodically the filter is backwashed automatically and these oxidized

particles are flushed down the drain to a drain pit or septic system. Unlike

regular greensand systems, no potassium permanganate powder is required.

Home | Online Storefront | Water Problems | Technical Resources | Contact Us | Company Info

Clean Water Systems & Stores, Inc. 2806-C Soquel Ave, Santa Cruz, California 95062

Phone: 831-462-8500 Fax: 831-476-0832

Call us Mon. - Fri. 10AM - 8PM Eastern Time or 7AM - 5PM Pacific Time!

We ship from our warehouse in Ohio for fast Midwest & East Coast service.

For West and Southwest orders, we ship from our warehouses in California or Arizona.

©Copyright 1997-2008 Clean Water Systems & Stores, Inc., All Rights Reserved

How To Treat Odors In Well Water

The incidence of “rotten egg” sulfur odors and black or gray water in hot and

cold water lines are due to the reaction of sulfates and microorganisms in

water. This can occur in the well directly, or in the household plumbing in

both hot and cold water pipes, or in only the water heater and hot water

lines.

Cold Water Odor or Hot Water Odor?

To determine the source of the odor and decide on the type of treatment

required, it is important to first check to see whether the cold water contains

odor, or just the hot.

Toilet tank with black

slime caused by

hydrogen sulfide gas

and sulfer bacteria..

• Run the hot water to notice the odor. Then move to another faucet and run

the cold water. If the cold water has an odor, then the source is in the cold

water.

• If the hot water alone has odor, then the odor is occurring primarily in the

water heater.

• Next go outside and determine if the well water contains odors directly

from the well by running water outside the home, before it enters the home

piping.

Sulfur and iron

bacteria can create

rotten-egg odors in

water heaters unless

treated .

Odors Caused by Bacteria & Sulfates

Some well waters contain an excessive amount of sulfates with various

strains of sulfate bacteria. These bacteria, while harmless to health, will react

in stagnant water that has been depleted of oxygen, and will produce

hydrogen sulfide gas.

If your well water is used directly from the well, and not aerated in an

atmospheric (non-pressurized) storage tank, then the odors are most likely

caused by anaerobic bacteria. These types of bacteria thrive in oxygendeprived environments, and often on waters high in sulfates. If the cold water

entering the home contains no odor, odor can still develop in cold water

piping in the home, especially in galvanized iron piping. Often iron piping in

the house is of an older age and can be corroded, providing a good

environment for the bacteria to grow and odors to develop.

Metering pumps used

to inject chlorine

bleach.

If there is an odor in the cold water inside the home, but not directly from the

well, see if the piping is iron piping, and then replace it with copper. As a

first step to this process, one can shock-chlorinate the piping and sanitize it,

and see if the odor can be eliminated.

Water Heater Odors

Water heater showing

sacrificial anode rod.

If the water is in the hot water only, then a shock-chlorination of the water

heater and servicing or replacing the anode rod in the water heater can

eliminate this problem.

Almost all water heaters have “anode rods” which in a cathode-anode

reaction, produce excess ions that wear off the anode rod and adhere to the

inside glass lining of the water heater, preventing corrosion. These bacteria

(typically the “desulfovibrio” or a related species) can be killed with

adequate amounts of chlorine by periodic shock chlorination, or by

continuous ozone or chlorination, or by turning up the water heater to

extremely high (often dangerous) temperatures.

Odors Present Directly From Well Water (outside house)

One of the following methods is typically used to remove hydrogen sulfide

gas from well water:

• Periodic shock chlorination with high doses of chlorine

Greensand filter with

potassium

permanganate alone

removes odors, but

works better with

chlorine feed.

• Aeration of the water to oxidize the hydrogen sulfide gas, combined with

periodic shock chlorination.

• Chlorine, hydrogen peroxide, or ozone injection alone

• Filtration of the odor by greensand media, activated carbon or other filter

media

• Chlorine, hydrogen peroxide, or ozone injection followed by filtration with

greensand, activated carbon or other media.

Periodic shock chlorination with high doses of chlorine

Ozone generator used

for odor removal from

well water.

This involves injecting into the well, pump system and piping a 50 to 200

ppm dose of chlorine. The chlorine residual is allowed to sit in the well for 6

to 24 hours, and then the water is pumped out until the chlorine residual is

gone. This will typically eliminate the odor problem temporarily. If the odor

returns, often within a couple of days to a few weeks, the procedure can be

repeated. If after a couple of repeated shock-chlorination procedures, the odor

is still present, one of the other methods will need to be used.

Aeration of the water to oxidize the hydrogen sulfide gas, combined with

periodic shock chlorination.

Since the bacteria that create the hydrogen sulfide odor are usually anaerobic,

or bacteria that cannot thrive in oxygen rich environments, often aeration in a

non-pressurized vented holding tank is beneficial to eliminate and drive off

the gas into atmosphere. This works best if the pH is low (less than 7.0) since

the hydrogen sulfide gas at pH higher than 7.0 will not easily gas off

completely.

Continuous Chlorine Injection

Odors can be controlled in water by chlorination, followed by retention or

contact time and aeration. See Fig. 1. Chlorine is a powerful oxidizer, and

while not as powerful as ozone by weight, is less expensive to install and

operate than ozone systems.

Usually 2.0 to 3.0 ppm of chlorine is injected for every 1 ppm of sulfide,

however if the pH is over 7.8 it can take up to 5 to 10 ppm of chlorine per 1

ppm of sulfide to treat hydrogen sulfide. If the pH is over 8.0 we usually

recommend ozone or hydrogen peroxide injection instead of chlorine bleach.

Hydrogen Sulfide Test

Kit

With chorine, as ozone, contact time and concentration of the chlorine is

critical. The chlorine can be injected either in before an open atmospheric

holding tank (Figure 3) or injected under pressure using a metering pump and

a contact tank or pressure tank. Chlorine injection followed by a contact tank

and a good backwash filter system is the more thorough approach.

Fig. 1 Chlorine Injection with non-pressurized tank

Ozone

There are two main methods for injecting ozone into water. In Method 1, (see

Figure 1) an open holding tank of at least a 200-gallon capacity is used.

Larger holding tanks up to 5000 gallons work better. A compressor or blower

is set up on a timer, or wired in so that when the well pump runs, the ozone

blower system runs. The air compressor is hooked up to a ceramic diffuser

stone, creating a large volume of tiny air bubbles.

If sufficient air is used, and the hydrogen sulfide levels are low, this method,

combined with periodic shock chlorination works well. Shock chlorination is

required to keep the levels of bacteria down in the well and holding tank.

In the open bubbler tank design, a UV generated ozone generator can be

used. The UV-generated ozone systems produce lower concentrations of

ozone but lots of aeration is used, and these ozone generators cost a lot less

than corona-discharge generators. Aeration and residence time allow the

hydrogen sulfide gasses to be oxidized and odors eliminated.

In the second method (Figure 2) , ozone is injected via a venturi under

pressure, as the water flows through a contact tank. This type of ozone

injection usually requires higher concentrations of ozone and typically a

corona-discharge generator with dry air or oxygen feed gas is used.

Since there is less residence time and the ozone is under pressure, as the

water is flowing through the contact column. This type of ozone injection

does not require an open holding tank and second booster pump. It does

require an ozone generator capable of putting out a much more concentrated

level of ozone gas, and stainless steel tanks, or ozone-resistant plastic tank

must be used to avoid corrosion problems.

Usually, after either types of ozone injection, in Figure 1 or Figure 2,

filtration is required. Depending on the water chemistry, filtration by

greensand, sand and anthracite, or activated carbon filters are used. These

types of filters are periodically backwashed to keep the media clean and free

of trapped sulfides, iron or manganese oxides.

Fig. 2 Ozone injection and contact tank

Removal of Odors by Filtration

Hydrogen sulfide gas odors can be removed by filtration but results vary, and

usually filtration alone is not effective. The reasons for this are that typically

odors and hydrogen sulfide gas are the result of bacterial action. Often the

odors can be removed at point of entry to the home or business, and then

develop again in the piping system and water heater.

It is more effective to use filtration after aeration, ozone, peroxide or chlorine

injection for best results. In some applications, with low levels of hydrogen

sulfide gas odors, greensand media filters, regenerated with potassium

permanganate are the very effective in removing hydrogen sulfide or rotten

egg odors.

Activated carbon is less effective and the life of activated carbon media beds

are short, and often require frequent replacing, sometimes within a few weeks

after installing the carbon filter.

A very effective and low cost method of hydrogen suflide gas removal is by

injecting chlorine or hydrogen peroxide, followed by a Greensand-Plus filter.

Greensand-Plus is an improved type of greensand filter media that does not

require potassium permanganate. A slight chlorine residual can be left in the

water after the filter, so that the pipes and water heater are kept disinfected,

elmininating any chance for odors redeveloping in the household piping.

Figure 3

Greensand Plus Iron & Odor Filtration System

See Figure 3. The booster pump is controlled by pressure switch. When

pressure in pressure tank drops below the cut-in point on the pressure switch

the booster pump and metering pump turn on. As water is pumped through

the system, a small amount of chlorine or hydrogen peroxide is pumped into

the water by the metering pump.

As the water flows into the contact tank, the chlorine is thoroughly mixed in

the water, allowing contact time to kill any bacteria and oxidize any iron,

manganese or hydrogen sulfide gas. Precipitated oxidized particles of iron,

sulfides and manganese are filtered out of the water by the greensand-plus

media filtration system.

Periodically the filter is backwashed automatically and these oxidized

particles are flushed down the drain to a drain pit or septic system. Unlike

regular greensand systems, no potassium permanganate powder is required.

Home | Online Storefront | Water Problems | Technical Resources | Contact Us | Company Info

Clean Water Systems & Stores, Inc. 2806-C Soquel Ave, Santa Cruz, California 95062

Phone: 831-462-8500 Fax: 831-476-0832

Call us Mon. - Fri. 10AM - 8PM Eastern Time or 7AM - 5PM Pacific Time!

We ship from our warehouse in Ohio for fast Midwest & East Coast service.

For West and Southwest orders, we ship from our warehouses in California or Arizona.

©Copyright 1997-2008 Clean Water Systems & Stores, Inc., All Rights Reserved

How to Treat Iron Bacteria in Home Well

and Tap Water

By: Gerry Bulfin

Iron bacteria consume iron to survive and in the process metabolize the iron into a

protective slime layer around the cells, making them very resistant to elimination. Iron

bacteria do not cause health problems but do leave a reddish brown or yellow slime that

can clog plumbing and foul water softeners and iron filters.

You may notice this brown or rust colored stringy-appearing slime in your toilet tank

when you remove the lid. In addition to causing plumbing and fixture problems iron

bacteria clog well screens and reduce well yields. Iron bacteria can produce odors that

may resemble fuel oil, cucumber, or sewage. These odors may be noticeable only in the

morning or after periods when the water has not been used. Iron bacteria can co-exist

with various species of sulfur bacteria which can give off a rotten-egg odor.

Treating Iron Bacteria by Shock Chlorination

Even though chlorine is a powerful disinfectant, iron bacteria can build up a thick slime

that keeps the disinfectant from penetrating beyond the surface cells. In addition, iron,

manganese and hydrogen sulfide gas that are often present in well water can absorb much

of the chlorine before it has a chance to reach the bacterial cells. Because chemical

reactions are slowed at the cool temperatures common in wells, bacterial cells need a

long exposure for chlorine or other disinfectants to be effective. Even if chlorine kills all

the bacterial cells in the water, those in the groundwater can be drawn in by pumping or

drift back into the well.

Because of these factors, thoroughly treating an iron bacteria infestation requires more

than simply dumping bleach into the well. The following steps are recommended:

Approximately 8 quarts of 5.25% household chlorine bleach should be mixed with 100

gals. of water. The goal is to prepare an amount more than the amount of water standing

in the well, and so the 100-gallon measure is a safe estimate if this is not known. You can

mix this water in several clean trash containers.

Pour or pump the solution into the well. Attach a hose to an outside hose bib or faucet

and place the other end of the hose into the well. Open the faucet and circulate the water

for at least one hour washing down the inside of the casing and the pump piping. Faucets

in your house should be opened until you detect a chlorine smell, and then close them.

Allow the chlorine solution to remain in the well and piping for at least 24 hours, before

purging the system free of the chlorine. If you have a chlorine test kit, make sure there is

at least 10 ppm of chlorine left in the well water after the 24 hours. If you detect a

chlorine residual less than 10 ppm, repeat the entire shock chlorination process if

possible.

Run the chlorinated water outdoors on a field or ditch since it can have a negative effect

on septic tanks. It may also kill grass and shrubs, and under no circumstances should be

run into a pond or stream.

Well owners may need to repeat this process more than once in order to rid the system

entirely of the iron bacteria.

Prevent Iron Bacteria Infestations

When a new well is drilled, or when an existing well pump is repaired, soil containing

bacteria can be introduced into the groundwater from pipes or pumps that were laid on

the ground. Surface water used as drilling water may also infect the well with iron

bacteria.

An improperly constructed or maintained well can be contaminated by surface water

leaking into the well. In some cases floods will force surface water into the well and

cause contamination. Poorly maintained or defective septic systems, barn or cattle areas,

and other sources of contamination may allow water containing bacteria to penetrate the

well through open cracks in the bedrock.

Although these sources may cause more serious water quality problems which could

cause disease (such as e.coli bacteria, parasites and viruses) they could also be sources of

iron bacteria in a well.

Well Chlorinators

In many cases the iron bacteria are not eliminated despite repeated attempts to sanitize

the well and plumbing. At this point a permanent and on-going disinfection system may

be employed.

Chlorine is the most common disinfectant used in home water well systems, but hydrogen

peroxide and ozone are also highly effective against iron bacteria. If the well is losing

production due to iron bacteria slime and build-up a chlorine pellet feeder that dispenses

chlorine pellets down the well may be the best solution.

The chlorination, peroxide or ozone injection system is typically installed after the well

but before the water enters the household piping in order to disinfect the water of iron

bacteria. A large enough contact tank must be employed in order for the water to be

thoroughly disinfected after injecting the disinfectant.

Article Source: ABC Article Directory

Gerry Bulfin is a licensed water treatment contractor and WQA Certified Water

Specialist IV specializing in treating bacteria in well water. He may be contacted through

the website www.cleanwaterstore.com or by calling 831-462-8500 or by emailing him

here.

Disinfecting A Well Contaminated With Bact

and/or Hydrogen Sulfide Odors

DISINFECTING A WELL

using chlorine bleach*

I recommend using hydrogen peroxide instead

1.

1. Remove well cover. Pour the required amount of bleach into the well. SEE TABLE BELOW.

2.

2. Run ALL faucets in the house, one at a time, until you smell the chlorine at the faucet.

This ensures that the whole system will be disinfected.

3. Connect a garden hose to an outside tap or an indoor tap with the correct thread

fitting. Put the other end of the hose into the well, turn on the faucet, and from

time to time move the hose so that the chlorinated water bathes the sidewalls of

the well casing. Do this for at least six hours. Turn off tap and remove the hose

from the well.

4. Replace the well cover.

5.

6.

5. DON’T USE THE WATER for at least twelve hours. Forty-eight hours in optimal.

6.Run the water to waste but NOT IN THE SEPTIC SYSTEM for several hours, or until the chlorine

taste is dilute enough to be unobjectionable. The best way to run the water to waste is to use the

garden hose mentioned above (item 3). Direct the hose into an area where the chlorinated water

will not cause environmental damage or affect the water supply of others. For a typical well, this

may take 3-4 hours.

NOTE: To avoid pump overheating and possible damage, turn off the water when flow is at a trickl

and wait at least 15 minutes before turning on the pump again

7. After a week of use, retest for bacteria.

8. In some cases, one chlorination treatment WILL NOT be sufficient. Repeat disinfection procedur

as needed. You can also use calcium hypochlorite granules to provide a continuous release of

chlorine in your well.

Be sure to have a whole house KDF/Activated Carbon filter in place if you’re going to add

chlorine to your well. You can use a by-pass valve to circumvent it when disinfecting the house

pipes.

Well Depth

Amount of Liquid Household Bleach

Up to 150 ft

One Quart

151 to 300 ft

Two Quarts

over 300 ft

One Gallon and 1 cup crushed

swimming pool tablets

Source: Ohio Department of Natural Resources

* My comments:

It is my opinion that you can never entirely disinfect a contaminated well. Think about it.

You're using chlorine to attempt to eliminate every single individual bacteria. No. What you're doi

is buying some time. The population will slowly rebuild. When you use chlorine you also release

dangerous trihalomethanes into your water supply. These are very dangerous but can be removed

with the proper filtration.

I recommend using hydrogen peroxide in place of chlorine. Both are oxidants. Hydrogen

peroxide does not last as long in the well. It dissipates, converting to water and oxygen. Thus, yo

may have to repeat the treatment more often, but the byproducts are not hazardous. Apparently

though if you have bromides in your well it can convert these to bromates which do have health

impacts. As always, it is best to test before proceeding.

I have instructions for disinfection using hydrogen peroxide. You can purchase those here for $75:

Instructions for Treating a Well using Hydrogen Peroxide

Some people recommend the use of calcium hypochlorite granules to provide slow release of chlori

in a well to control bacteria, iron, or hydrogen sulfide odors.

I try to stick with all natural non-toxic methods whenever possible.

If you have a problem with bacteria I would recommend that you also install a 5 micron filter,

followed by an Ultra Violet light, followed by a 1 micron filter. This will kill the bacteria as they ent

your home.

Further thoughts....

Be aware of activities in your community that can put your drinking water at risk. Talk to your

neighbors to determine if problems with your drinking water are individual or community-wide.

Check out the history of the area in which you live to determine if past activities are having a

present impact on your drinking water.

And manage your own septic tank if you have one. Replenish it on occasion with bacteria (I use

Roebic K-37, which you can buy at any hardware store) to aid in digestion and limit your use of

chemicals in the house, such as bleach, Lysol, and other sanitizers, that will kill the bacteria in the

septic. Visit my link on using natural cleaning products to learn more.

***

You may return to my water purification products and services here:

Water Products, Water Tests, and Services

James P McMahon

Ecologist

866-691-4214

(toll-free)

leave messages or press #1 to reach me directly

or

435-574-2711

(direct)

©

Sweetwater, LLC

"When you drink the water, think of the spring"

Return to:

www.cleanairpurewater.com

**

Sweetwater Healthy Home Environments

Water purification systems - Whole house and kitchen, water softeners. Consultant for specific water problems.

375 Cedar Tree Dr.

Brookside UT 84782

Phone: 435-574-2711 E-mail Web

If you want a whole house water purification systems that will give you the most comprehensive protection availab

along with the best tasting, best showering, bathing and the healthiest water you've ever experienced, call me. M

name is Jim McMahon and I help people achieve healthy water in their homes.

(C) 2004

Sweetwater, LLC 375 Cedar Tree Drive, Brookside, UT 84782

Home

Site Map

Water Testing

Consultations

Water Purifiers

Arsenic Removal

Air Purification

Affiliate Links

Ultimate Guide

Iron Removal

Biography

Resource Library

Healthy Communities

Commercial

Well Water

Rave Reviews