Utilization of municipal sewage sludge as additives for the

advertisement

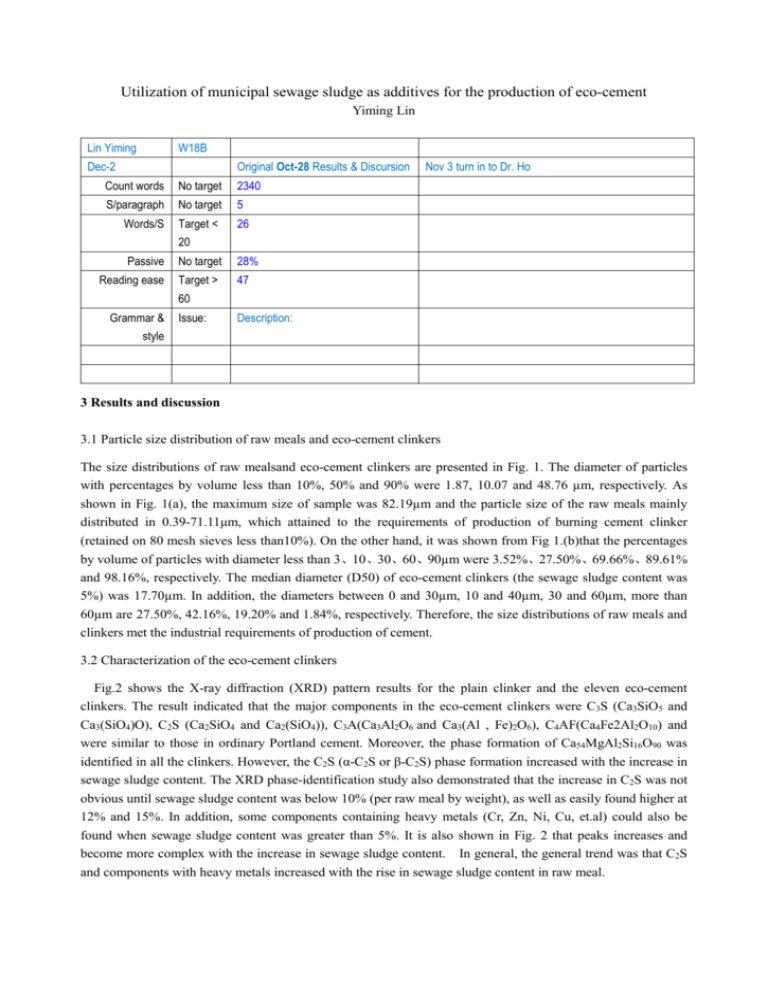

Utilization of municipal sewage sludge as additives for the production of eco-cement Yiming Lin Lin Yiming W18B Dec-2 Original Oct-28 Results & Discursion Count words No target 2340 S/paragraph No target 5 Words/S Target < 26 Nov 3 turn in to Dr. Ho 20 Passive No target 28% Reading ease Target > 47 60 Grammar & Issue: Description: style 3 Results and discussion 3.1 Particle size distribution of raw meals and eco-cement clinkers The size distributions of raw mealsand eco-cement clinkers are presented in Fig. 1. The diameter of particles with percentages by volume less than 10%, 50% and 90% were 1.87, 10.07 and 48.76 µm, respectively. As shown in Fig. 1(a), the maximum size of sample was 82.19µm and the particle size of the raw meals mainly distributed in 0.39-71.11μm, which attained to the requirements of production of burning cement clinker (retained on 80 mesh sieves less than10%). On the other hand, it was shown from Fig 1.(b)that the percentages by volume of particles with diameter less than 3、10、30、60、90µm were 3.52%、27.50%、69.66%、89.61% and 98.16%, respectively. The median diameter (D50) of eco-cement clinkers (the sewage sludge content was 5%) was 17.70µm. In addition, the diameters between 0 and 30µm, 10 and 40µm, 30 and 60µm, more than 60µm are 27.50%, 42.16%, 19.20% and 1.84%, respectively. Therefore, the size distributions of raw meals and clinkers met the industrial requirements of production of cement. 3.2 Characterization of the eco-cement clinkers Fig.2 shows the X-ray diffraction (XRD) pattern results for the plain clinker and the eleven eco-cement clinkers. The result indicated that the major components in the eco-cement clinkers were C3S (Ca3SiO5 and Ca3(SiO4)O), C2S (Ca2SiO4 and Ca2(SiO4)), C3A(Ca3Al2O6 and Ca3(Al , Fe)2O6), C4AF(Ca4Fe2Al2O10) and were similar to those in ordinary Portland cement. Moreover, the phase formation of Ca54MgAl2Si16O90 was identified in all the clinkers. However, the C2S (α-C2S or β-C2S) phase formation increased with the increase in sewage sludge content. The XRD phase-identification study also demonstrated that the increase in C2S was not obvious until sewage sludge content was below 10% (per raw meal by weight), as well as easily found higher at 12% and 15%. In addition, some components containing heavy metals (Cr, Zn, Ni, Cu, et.al) could also be found when sewage sludge content was greater than 5%. It is also shown in Fig. 2 that peaks increases and become more complex with the increase in sewage sludge content. In general, the general trend was that C2S and components with heavy metals increased with the rise in sewage sludge content in raw meal. :Ca3(Al,Fe)2O6 0% :C3A;:C2A;:CaAl2Fe4O10; 3.0% Intensity Intensity 1.0% 8.0% 1.5% 10.0% 2.0% 12.0% 2.5% 15.0% 20 :Ca3(Al,Fe)2O6 5.0% 0.5% 10 :C3A;:C2A;:CaAl2Fe4O10; 30 2θ 40 50 60 70 10 20 30 2θ 40 50 60 Fig.2. XRD patterns of eco-clinkers. 3.3 Microstructure of co-cement clinkers by SEM To verify the X-ray diffraction (XRD) pattern results for the plain clinker and the eleven eco-cement clinkers, SEM examinations were performed. Fig. 3 shows the microstructure of clinkers with sewage sludge content of 0% (a), 2.5% (b), 5.0% (c), 10.0% (d) and 15.0% (e). It was found that different addition of sewage sludge led to discrepancies in the microstructure of the clinkers. As shows in Fig 3a, C3S, C2S and intermediate phase structure are clearly seen. However, as the addition of sewage sludge C3S structures decreased, which can be seen from Fig b and Fig c that are less than Fig a, as well as Fig d and Fig e have the least. On the other hand, C2S structures increased with the increases of sewage sludge content. In addition, as shown in Fig. 3(e), it can also be observed that the microstructure of mixture containing 15.0% sewage sludge content showed significant differences in the morphology compared with other samples and a lager amount of pores distributed in the clinker. Results from the X-ray diffraction (XRD) pattern showed that C2S was one of the major content in the sample and one possible explanation was that the amount of components in sludge led to the increases in pores. Furthermore, reports showed that it was most likely that the doped heavy metals (especially Zn) changes the viscosity of liquid phase of clinkers during the burning process and it had an influence on the total porosity and the distribution of pores [19]. 70 Fig.3. SEM micrographs of the eco-cement clinkers with the addition of different sewage sludge in raw meals: (a) 0%, (b) 2.5%, (c) 5.0%, (d) 10.0% and (e) 15.0%. 3.4. Setting times of the eco-cement pastes The setting times for the twelve types of the plain paste and the eco-cement pastes are given in Table 2. The results showed that the initial setting time and final setting time were 136 and 185 min, respectively. All the eco-cement pastes had a bigger initial setting times and final setting times as well than plain paste in comparison with the plain paste. These times increased as sewage sludge content in raw meal increased. It may be due to a coagulant structural network forms from the residual cement, which resulted hydration slows [20]. Moreover, other possible explanation was that it may be attributed primarily to the increase in C2S (α-C2S or β-C2S), which affected the rate of the pozzolanic reactions. On the other hand, these delays could also be due to some minor elements (Zn, Cr et al.) presented in sewage sludge, which may dissolve in the pore solution and then affect the hydration of the cement [8, 19, 21]. 3.5 Strength development of plain paste and eco-cement pastes Flexural and compressive strengths of the plain paste and eco-cement pastes after 3, 7 and 28 days are also shown in Table 2. It could be seen that the flexural and compressive strengths of the plain paste and eco-cement pastes developed when the curing age extended from 3 to 28 days. In comparison with the plain paste, the results demonstrated that the flexural and compressive strengths of eco-cement paste were similar to that of plain paste with the same conditions. However, it could be seen that the increase in sewage sludge content in raw meals led, for curing age of 3 and 7 days, to a greater decrease in flexural strength, as well as a little decrease in compressive strength. But, from 7 to 28 days, the flexural and compressive strengths increased and became similar to that of plain paste. Moreover, the strengths were decreased in all hydration times when the sewage sludge content in raw meals is 15%. The decrease in early strengths (at 3days) may be partly due to the changes in content of pozzolanic active matters in sewage sludge [3], which are thought to be less effective in pozzolanic reaction and delays the early hydration. As mentioned above, the amounts of C2S (α-C2S or β-C2S) and initial setting times increased as the sewage sludge content in raw meal increased. So the lower early strength may be responsible for the delay in the process of hydration. On the other hand, as sewage sludge is a hazardous solid waste which contains various matters, especially minor elements, it would led to the changes of clinkers and form news compounds in the burning process when it was added in the raw meal. Further study is needed in the next section. Table 2 Setting time, Flexural strength and Compressive strength of plain and eco-cement mortars Setting time Flexural strength (MPa) (hour : minute) Curing time(days) Start Final 3 7 28 3 7 28 0 2:16 3:05 6.02 7.56 9.65 31.42 45.27 63.15 0.5 2:19 3:12 5.98 7.55 9.62 30.28 44.79 62.56 1.0 2:20 3:13 5.75 7.62 9.67 32.59 43.66 64.01 1.5 2:28 3:25 5.74 7.69 9.59 32.63 42.55 61.72 2.0 2:35 3:35 5.65 7.59 9.62 31.78 43.51 65.44 2.5 2:40 3:45 5.43 7.53 9.62 28.07 43.33 63.52 3.0 2:42 3:46 5.41 7.51 9.65 30.02 42.58 63.48 5.0 2:46 3:49 5.22 7.52 9.56 31.25 43.21 62.58 8.0 2:55 3:55 5.21 7.56 9.61 30.02 41.85 61.95 10.0 3:10 4:08 5.16 7.35 9.49 29.95 42.68 60.64 12.0 3:12 4:17 5.08 7.16 9.45 29.86 40.28 60.98 15.0 3:20 4:23 4.98 7.02 9.55 28.64 39.33 60.48 Sewage sludge content (%) Compressive strength (MPa) 3.6 Changes of the element content of eco-cement clinkers The element concentration of Al, Fe, Mg, Ti, Mn, Sr, Ba, Zn, Cr, Cu, Ni and Pb in the plain and eco-cement clinkers was analyzed by ICP-AES. The results of these elements are shown in Fig. 4. It could be seen that Al and Fe, known to be the main compounds of the cement, decreased slightly as sewage sludge content in raw meal increasd. But study showed that properly increasing the amount of aluminum oxide could enhance early hydration and increase the early strength of the paste [22], it may be partly led to the increase in the initial setting time and the lower early strengths of the eco-cement pastes by contrast a decrease in these two elements. Although a small amount of Ti and Mn oxide can increase the strength of the pastes, the results from publications [23] showed that the increase of these elements slightly retard the hydration during the first 2 days and their effect on the hydration rate tends to become negligible at 28days. As shown in Fig. 6, the Ti increased as the sewage sludge content in raw meal increased while the Mn did not have obvious change. So these two elements may play a role to the later ages (7 to 28 days) strengths. Moreover, the temperature and viscosity of the formation in the liquid phase can be reduced when a small mount of Mg is added to the raw meal. However, it was found from the Fig. 4 that the Mg decreased with increase in the sewage sludge content in raw meal, therefore, it may has negative effects on the formation and development of the alite crystals [24] and it may be partly due to the increase in C2S in the eco-cement clinkers. In addition, the Ba and the Sr can have an influence on the ability of stabilizing β-phase and and the crystal size. Although Ca, Ba and Sr are the chemical elements of the same clan and Ba increased as the sewage sludge content in raw meal increased, the Sr decreased obviously and had a higher concentration than Ba. So the change of Sr and Ba may have a contribution to the delay of hydration times and the early lower strengths. The heavy metals Cr, Zn, Cu can have an influence on the strength of cement mortar and the initial setting or hydration of the cement when their concentrations are higher than normally present in the clinker. Stephan [19, 21, 25, 26] found that Cr accelerated the hydration and the initial setting of the cement, lowered the strength and caused changes of the content of free lime and the modification of C3S in the clinkers at higher concentration. The results were similar to Shirasaka et al. [27] and Murat et al [28]. Moreover, the results from publications [19, 23, 26, 28, 29] found that Zn retarded the heat liberation, delayed the hydration of cement and also led to a retardation of the initial setting but also caused higher strength of the cement pastes. In addition, the Cu also was found that it was the greatest delay of the hydration rate of cement in all the elements [23, 27]. As shown in Fig. 6, the Cr, Zn, Cu content increased as the sewage sludge content in raw meal increased and the concentration of Zn is higher than that of Cr, Cu also is the lowest. Although the concentrations of these three elements were low, the incorporation of them may partly have the mainly effect on the increase in the initial setting time and the lower early strengths of the pastes, as well as the increase in C2S in the eco-cement clinkers. On the other hand, most publications [19, 21, 23, 25, 26] showed that the addition of Ni in raw meal did not affect the hydration of cement. Several heavy metals, known to be volatile, will immediately vaporized during the melting process, such as lead and cadmium. Therefore, these elements are not analyzed in this study. Generally, most of the elements changed in the cement clinkers could have an influence on the properties of the cement pastes and further studies must to be carried out to verity it. Fig.4. Changes of the element content of plain and eco-cement clinkers with different sewage sludge contents in raw meals. 3.7 TCLP test of eco-cement clinkers Table 3 shows the leaching concentrations of heavy metals and the identification for the extraction procedure toxicity criteria of China. It can be seen that only Ba, Cr, Pb and Sr are present but none of them exceeded the regulatory thresholds. Moreover, , the increase in sewage sludge in raw meal resulted in higher amounts leached for almost all heavy metals by comparing with the leaching data between each eco-clinker. This could be due to the higher heavy metal content in the clinkers when using sewage sludge, leading to an increase in the amount of heavy metal available for leaching. However, in fact, all of the heavy metals are barely detectable. This result could be related to either a parts of these heavy metals (primarily volatile metals) evaporated during the clinkers burning process, or a parts of them could substitute with the major elements (Ca, Si, Al, Fe) so that they were remained and immobilized in the structure of clinker minerals. In all cases, all the eco-cement clinkers produced in this study were leach-safe and harmless to the environment. Table 3 TCLP leaching concentrations (mg/L) and the finally pH of mixed liquids for the plain and eco-cement clinkers Sewage sludge content (w/w %) GB Elements(mg/L) pH Ba Cd Co Cr Cu Mn Ni Pb Sr Ti V Zn 0 11.68 1.14 ND ND 0.39 ND ND ND ND 6.06 ND ND ND 1.0 11.55 1.41 ND ND 0.09 ND ND ND 0.02 6.52 ND ND ND 3.0 11.66 1.70 ND ND 0.02 ND ND ND ND 6.68 ND ND ND 8.0 11.49 2.09 ND ND 0.32 ND ND ND 0.01 7.03 ND ND ND 12.0 11.21 2.02 ND ND 0.83 ND ND ND 0.01 6.64 ND ND ND — 100 1 — 5 100 — 5 5 — — — 100 5085.3-2007a “a” Identification standards for hazardous wastes- Identification for extraction toxicity of China.