EPA Risk Management Program

advertisement

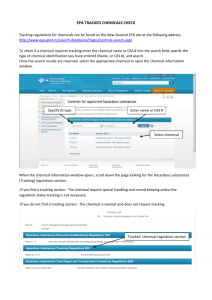

EPA Risk Management Program Risk Management Plan (RMP) is a regulation promulgated by the Environmental Protection Agency (EPA) for Chemical Accident Release Prevention (40 CFR 68). This federal regulation was mandated by section 112(r) of the Clean Air Act Amendments of 1990. The regulation requires facilities to develop and implement proper risk management program to mitigate risk, in term of frequency and severity of chemical plant incidents1. The EPA requires a performance-based approach towards compliance with the Risk Management Program regulation. Included in the RMP are description of the hazard assessment, prevention program, and the emergency response program. Environmental Protection Agency (EPA) Risk Management Program (RMP) also describes a methodology to conduct a process hazard analysis and it is included in section 40 CFR 68.67. RMP is mandatory for facilities that use more than a certain threshold quantity of regulated highly hazardous chemicals. These facilities submit its RMP to the EPA and subsequently the RMP is made available to governmental agencies, the state emergency response commission, the local emergency planning committees, and communicated to the public. In general, the Risk Management Program composes of four requirements: Hazard assessment Prevention program Emergency response program Documentation that is maintained on the site and submitted to federal, state and local authority and sometimes also shared to the local community. Each program of Risk Management Program is tailored to include at least one of the previous four elements, as the requirement of the elements will vary on different facility. Hazard assessment is a consequence analysis for all potential hazardous chemical releases, including worst-case scenario and history of releases at the facility. The worst case release is defined as the release of the largest quantity of a regulated substance from a vessel or process line failure, including administrative controls and passive mitigation that limit the total quantity involved or release rate. 1 Crowl, D. A, Louvar J. F, Chemical Process Safety Fundamental with Application, U.S. Prentice Hall, 2002. The EPA requires hazard assessment to analyze consequence of the following worst-case scenario: 1. A single worst-case release scenario is analyzed for all covered flammable materials on the site and only one flammable substance is analyzed for other more likely scenarios. 2. A single worst-case release scenario is analyzed for all toxic substances on the site and more likely releases are analyzed for each toxic substance available and covered by the regulation. The Risk Management Program requires only the analysis of consequence and not the probability of an incident scenario. Therefore, the analysis is not a true determination of risk which is a join of probability and consequence. The second requirements, Prevention program has 11 elements which are relatively similar to PSM standards. In many ways the EPA- RMP is very similar to OSHA PSM because the EPA attempted to have the same requirements wherever possible as PSM-OSHA. However, difference exists because EPA and OSHA have different responsibilities. RMP is designed specifically for off-site people and environment protection whereas PSM is designed specifically for on-site people protection. Comparison of prevention program between Process Safety Management (OSHA) and Risk Management Plan (EPA) is shown in Table 1. Table 1. Prevention program of Process Safety Management (OSHA) and Risk Management Plan (EPA)2 Process Safety Management (OSHA) Process safety information Process Hazard Analysis Operating Procedures Employee participation Training Contractors Pre-Startup Safety Review Mechanical Integrity Hot Work permit Management of Change Incident Investigation Emergency Planning and Response Compliance Audits Trade Secret (No equivalence) 2 Idem as 1 Risk Management Plan (EPA) Process safety information Hazard evaluation Standard operating procedures (No equivalence) Training (No equivalence) Pre-start up review Maintenance (No equivalence) Management of change Accident investigations Emergency response Safety audits (No equivalence) Risk assessment The third requirement is emergency response program, which describe the steps needed in response to incidental releases of hazardous materials. The program also establishes procedures for notifying the local community and emergency response agencies. The fourth requirement is documentation. This part of RMP is pretty self explanatory. Steps to check for coverage and compliance requirements3 Facility may check to determine coverage and compliance requirements under the EPA Risk Management Program. There are four steps to follow, which are: 1. Check the list of chemical from the EPA Risk Management Program to determine if any of the chemicals are present in the facility and above the threshold quantity at any time. The threshold quantity determination is considered at the maximum that could be on site at any given time. Other considerations are proximity, interconnectivity concentration, and so on. In addition to the chemical list, EPA also provides rules for mixture and effect of dilution. If the threshold quantity does not exceed the list, then the facility is not subject to the EPA risk management program and steps 2-4 may be ignored. 2. If any of the RMP listed chemicals are confirmed to be present or above the threshold quantity, the facility must perform a worst-case scenario analysis. The If the impact zone from worst-case scenario does not contain any public receptors, the facility has had no incidents in the last 5 years, and the facility’s emergency response plan is coordinated with local emergency response officials; then the facility belongs in Program 1. 3. If the facility cannot claim coverage under Program 1and the facility is classified in any of the industrial classification codes or the facility is covered by the OSHA PSM regulation, then the facility belongs in Program 3 and must comply with Program 3 requirements. 4. If the facility does not belong in Program 1 or Program 3, then by default the facility is required to comply with Program 2 requirements. Table 2 shows all programs included in the EPA Risk Management Program. A significant characteristic of the EPA Risk Management Program is that the regulation provides a tiered program based on the risk and incident history of the facility. The regulation recognizes the fact that one size does not fit all and the risk management program is based on a three-pronged approach. First, the hazard assessment provides information about potential off-site 3 Lee’s Loss Prevention in The Process Industries Vol.1, Vol.2 and Vol.3 Hazard Identification, Assessment and Control 3rd Edition, Elsevier, 2004. consequences and the incident history of the facility. The prevention program and the emergency response program are then developed based on the hazard assessments. It should be noted that the prevention program requirements under Program 3 mirror the OSHA PSM program requirements. Table 2. Eligibility criteria and compliance requirements for different program levels EPA’s Risk Management Program regulation4 Program1 Program 2 Program 3 Program Eligibility Criteria No offsite accident history Process not eligible Process is subject to OSHA for program 1 or 3 PSM (29 CFR 1910.119) Process is SIC code 2611, 2812, 2819, 2821, 2865, 2869, 2873, 2879, or 2911 No public receptors in worst-case circle Emergency response coordinated with local responders Program Requirements Hazard assessment Hazard assessment Hazard assessment Worst-case analysis Worst-case analysis Worst-case analysis 5-year accident history Alternative releases Alternative releases Certify no additional steps needed 5-year accident history 5 -year accident history Management program Management program Document management Document management system system Prevention Program Prevention Program Safety information Process safety information Hazard review Process hazard analysis Operating procedures Operating procedures Training Training Maintenance Mechanical integrity Incident investigation Incident investigation Compliance audit Compliance audit Management of change Pre-startup safety review Contractors 4 Idem as 3 Emergency response program Develop plan and program Employee participation Hot work permits Emergency response program Develop plan and program