A. CE approved

advertisement

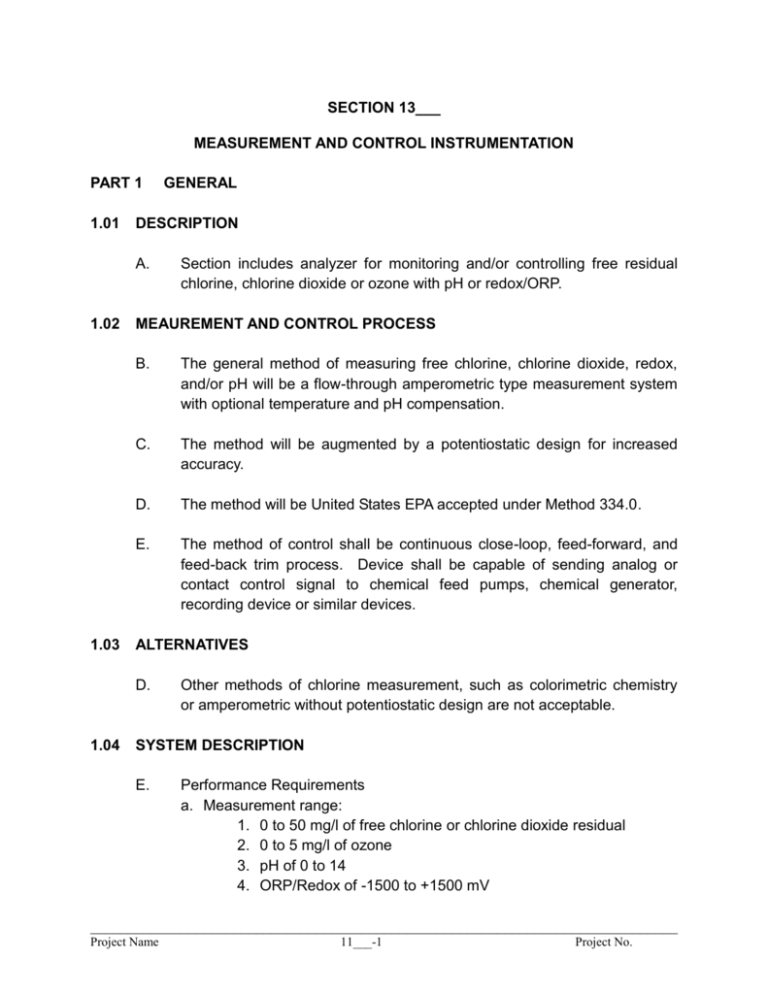

SECTION 13___ MEASUREMENT AND CONTROL INSTRUMENTATION PART 1 1.01 DESCRIPTION A. 1.02 1.03 Section includes analyzer for monitoring and/or controlling free residual chlorine, chlorine dioxide or ozone with pH or redox/ORP. MEAUREMENT AND CONTROL PROCESS B. The general method of measuring free chlorine, chlorine dioxide, redox, and/or pH will be a flow-through amperometric type measurement system with optional temperature and pH compensation. C. The method will be augmented by a potentiostatic design for increased accuracy. D. The method will be United States EPA accepted under Method 334.0. E. The method of control shall be continuous close-loop, feed-forward, and feed-back trim process. Device shall be capable of sending analog or contact control signal to chemical feed pumps, chemical generator, recording device or similar devices. ALTERNATIVES D. 1.04 GENERAL Other methods of chlorine measurement, such as colorimetric chemistry or amperometric without potentiostatic design are not acceptable. SYSTEM DESCRIPTION E. Performance Requirements a. Measurement range: 1. 0 to 50 mg/l of free chlorine or chlorine dioxide residual 2. 0 to 5 mg/l of ozone 3. pH of 0 to 14 4. ORP/Redox of -1500 to +1500 mV ______________________________________________________________________________ Project Name 11___-1 Project No. b. c. d. e. 1.05 CERTIFICATIONS A. B. C. 1.06 Operational Criteria a. Sample flow rate: 5.3-11.9 GPH (20 – 45 l/hr) b. Sample pressure: 3 to 43.5 psi (0.2-3 bar) with minimum 3 psi differential pressure c. Sample water temperature: 32-104°F (0-40°C) d. Ambient temperature: 32-113°F (0-45°C) e. Operating humidity: 90% at 104 degrees F (40 degrees C) maximum WARRANTY A. 1.08 CE approved EN 61000-3-2 and -3-3 EN 61010-1 ENVIRONMENTAL REQUIREMENTS A. 1.07 Accuracy: +/- 5% of range limit value Minimum detection limit: 0.02 mg/l (chlorine/chlorine dioxide/ozone) Resolution: 0.01 mg/l (chlorine/chlorine dioxide/ozone) Cycle time for each measurement: continuous and immediate The equipment/system warranty, unless otherwise stated, shall be warranted to be free of defects in material and workmanship for a period of 24 months from the date of installation, but not more than 30 months from the date of manufacture. MAINTENANCE SERVICE A. Scheduled maintenance: a. Electrodes and sensors: annually PART 2 PRODUCT 2.01 MANUFACTURER A. Grundfos 1. Model DIA-2Q 2.02 MANUFACTURED UNIT ______________________________________________________________________________ Project Name 11___-2 Project No. A. The DIA-2Q chlorine analyzer consists of a preassembled assembly containing a measuring cell, analyzer, and electrodes. All components are completely assembled and wired for user friendly installation. B. The DIA-2Q analyzer is housed in an IP65 rated enclosure. 2.03 EQUIPMENT A. Operational power shall be (115/120 VAC,50-60Hz)(24VDC)(230/240VAC, 50/60Hz) single phase power. B. The following operation modes shall be available: i. ii. iii. iv. On/Off control through digital contact Digital pulse frequency control Digital pulse duration control Analog P,PI, or PID control where the 0/4 to 20 mA signal from the analyzer is scaled to pace the pump or generator v. Compound loop to compensate for flow fluctuations. C. Output i. ii. iii. iv. D. Alarms i. ii. iii. iv. 2.04 Alarm NO/NC Contact Pulse frequency relay Pulse duration relay Four Analog 0/4 to 20 mA outputs: 1. Residual 2. pH 3. Temperature 4. PID Controlled output Low/High residual or pH alarms No sample flow Cleaning motor Alarm Control alarms COMPONENTS A. Standard equipment: ______________________________________________________________________________ Project Name 11___-3 Project No. a. b. c. d. e. f. 2.05 Analyzer Measuring cell with temperature and sample flow monitoring Chlorine/Chlorine Dioxide/Ozone residual and pH or ORP electrodes All items installed and wired on wall mounting kit Three reagent kit for pH calibration Installation and Operation manual B. Dimensions a. Width: 19.5 inches (495 mm) b. Height: 19.5 inches (495 mm) c. Depth: 4.8 inches (125 mm) C. Weight: 12 pounds (5.5 kg) D. The measuring cell shall be pressure-proof with motorized element for electrode cleaning. Additional cell components shall include integral filter, flow regulator, sampling valve, flow sensor and temperature sensor. The cell manufacturer shall supply a back pressure valve mountable on the cell discharge to ensure proper sample flow differential pressure. OPERATION A. B. C. D. The Analyzer shall be able to provide an analog control signal after applying a P, PI or PID controller to the measured values. The analyzer should be able to provide a compound loop control signal that accounts for flow fluctuations. The analyzer should be able to compensate for pH, temperature and flow fluctuations. The analyzer shall be equipped with a calibration function that calculates the slope of the measured values in mg/l against a micro-amp signal from the cell. 2.06 CONTROL The analyzer shall come equipped with at least 3 menu selectable control modes; interpulse, pulse frequency, continuous control. A. Interpulse 1. The analyzer will provide a relay output for which the pulse width is controlled for ON/OFF operation. ______________________________________________________________________________ Project Name 11___-4 Project No. B. Pulse frequency 1. The analyzer will provide a switching relay output of varying frequency to perform proportional control based on pulses. C. Continuous Control 1. The analyzer will provide a 0/4-20mA output for proportional, set-point or compound loop control with P,PI or PID internal setting option. D. The analyzer will also provide an option to select between setpoint or combined control where the approach to the setpoint can be upward or downward. E. An optional mode should also include a three point controlled output: Closed, half scale and full scale for applications where motorized type valves or servomotors are required. PART 3: EXECUTION 3.01 INSTALLATION A. 3.02 WARRANTY B. 4.01 The equipment shall be installed per the contract documents and manufacturer’s recommendations. The equipment/system warranty, unless otherwise stated, shall be warranted to be free of defects in material and workmanship for a period of 24 months from the date of installation, but not more than 30 months from the date of manufacture. ACCESSORIES A. Optional recommended accessories shall include: 1. 2. 3. 4. 5. Pressure regulation valves for inlet and outlet 100 micron filter (if necessary) Isolation valves for service on the cell External strainer assembly. Spare electrodes ______________________________________________________________________________ Project Name 11___-5 Project No.