NOTES_CEGE1009_7

advertisement

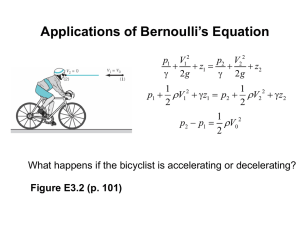

Monday 31st January 2011 Lecture 7 Resume:- Bernoulli equation:assumptions (steady, frictionless flow along a streamline) derivation (Newton's law applied) definition of stagnation pressure p0 , dynamic head, total head, measurement of static and dynamic pressures Applications of Bernoulli's Equation pressure distribution on structures in a uniform flow coefficient of pressure flow measurement and coefficients of discharge flow through an orifice venturimeter orifice plates weirs Distribute Problem Sheet #5 41 CIVIL, ENVIRONMENTAL and GEOMATIC ENGINEERING DEPARTMENT 1st YEAR FLUIDS CEGE1009 MECHANISMS 3.4 Applications of Bernoulli's Equation: 3.4.1 Pressure distribution around structures in a uniform flow In Section 3.3 above, we introduced the concept of a Stagnation Pressure p0 at a point where the streamline has zero velocity and the dynamic pressure has been converted into piezometric pressure (at the tip of a Pitot tube, for instance). It is usual to adopt the terms q and p to describe the undisturbed velocity and pressure respectively, upstream of the object inducing the stagnation pressure. The stagnation pressure can then be found from application of Bernoulli's equation along that streamline: p0 p 12 q2 p, q p∞, q∞ Stagnation point p0 We now consider the flow around a structure (submarine, chimney, bridge pier, etc.) placed in an initially uniform flow u . Defining the velocity q and the pressure p at any point along a streamline, we have: p 12 q2 p 12 q 2 which can be re-expressed: p p 12 (q2 q 2 ) Introducing a Pressure Coefficient Cp to describe the distribution of pressure round the structure, (or, at least, the streamlines that follow the body shape), Cp = 1 at the stagnation point, and is in general defined as: 42 Cp q p p which , substituti ng from above , gives : C 1 p 2 1 q q 2 2 If Cp < 0 , then q is greater than the upstream velocity q and p < p . Conversely, if Cp > 0, then q is less than the upstream velocity and p > p . For example, consider an airship moving horizontally at 40 m/s at low altitude where patm = 1.013 bar and = 1.23 kg/m3. Find the pressure at the nose, and the pressure and velocity at a point where Cp = - 0.4 p∞=patm; q∞=40m/s Cp=-0.4 Stagnation point p0 Firstly, applying Bernoulli to the streamline which ends at the stagnation point: p0 p 12 q2 101300 12 x1.23 x 40 2 102284 Pa Given that Cp = - 0.4, we can use the definition equations for Cp- above to find q and p: q i ) C p 0.4 1 u 2 ii ) C p and hence q 14 . x 40 47.3 m / s p p and hence 1 q2 2 p 12 C p q2 p 12 x0.4x1.23x40 2 101300 100900 Pa Note that for wind tunnels in which air is drawn smoothly from the surrounding laboratory, the "static" pressure p within the wind tunnel test section is less than the atmospheric pressure outside the wind tunnel. This can be predicted by applying Bernoulli's equation to a streamline entering the wind tunnel from a distant (and relatively tranquil) part of the surrounding laboratory. On the other hand, when a free jet of fluid is created by a fan or other form of motor driving an unconstrained flow through an otherwise undisturbed fluid, then the static pressure within the jet 43 is atmospheric. 3.4.2 Flow measuring devices i) Pitot-static tube: One of the most common methods of measuring the velocity of a fluid is by use of a Pitot-static tube (already referred to in section 3.3). The streamline which meets the tip of the Pitot tube is brought to rest, and the total head tapping then gives the stagnation (or total) pressure at that point in the flow. Meanwhile the static tappings around the circumference record the static pressure. Hence, when the two tappings are connected across a differential manometer, the reading is a measure of the dynamic pressure. p∞ p 21 u2 p0 p0 Hence p0 - p = ½ u2 and the free stream velocity u is given by: u 2( p0 p ) If a manometer is used to measure the pressure difference, it is important to remember that the density in the equation above is not the density of the manometer fluid ... ii) Flow through a sharp-edged orifice (for instance, predicting flow rate from a tank) h z1 p∞ Vena contracta Discharge Q at velocity u2 44 When flow takes place through a sharp-edged hole (orifice) in the bottom or side of a vessel containing a constant depth of fluid, h, it is possible to use Bernoulli's equation to predict the theoretical rate of flow through the hole. For the particular case where flow discharges as a jet from the bottom of a tank into the atmosphere (that is, at atmospheric pressure) and taking datum at the level of the bottom of the tank, we apply Bernoulli's equation to a typical streamline: 2 2 p1 u1 p u + + z1 = atm + 2 + 0 g 2g g 2g If the tank is of sufficiently large cross-sectional area relative to that of the orifice that the velocity u1 is negligibly small, and if the free water surface in the tank is at atmospheric pressure patm , then p1 is given by hydrostatic pressure [ = patm + g (h - z1 ).] Hence: 2 h u2 2g and thence u2 2 gh from which, given the area of the orifice and assuming the diameter of the orifice to be small relative to the depth of fluid in the tank, it is possible to deduce the volume flow rate. However, this derivation is flawed for a number of practical reasons, and the result for an "ideal flow" has to be adjusted in order to yield any useful formula. In the first place, the streamlines converge as they approach the orifice; but they cannot suddenly change direction at the orifice, and continue to converge beyond it until they eventually become parallel (approximately half an orifice diameter away). This point of minimum jet diameter is known as the vena contracta. With the streamlines now parallel and surrounded by air at atmospheric pressure, the pressure across the complete cross-section of the jet can then be assumed atmospheric also. [Note that with a jet discharging vertically, the fluid is accelerated by gravity and thus, by the continuity principle, the jet continues to contract. However this change in diameter is negligible in comparison to the rapid contraction between the orifice and the vena contracta.] Thus, the actual diameter of the jet when the fluid reaches atmospheric pressure is significantly less than the diameter of the orifice itself. The ratio of the two cross-sections is known as the coefficient of contraction Cc. It is also important to consider the effects of friction. Invariably, depending on the smoothness and thickness of the orifice, there is some friction where the fluid approaches the orifice and leaves the tank. The resulting loss of energy is usually quantified in terms of a coefficient of velocity Cv , which is the ratio between the actual velocity in the jet at the vena contracta and the "ideal velocity" calculated above. Because of contraction of the jet and friction, the actual discharge from the orifice is less than that predicted for an ideal fluid. The ratio between the actual discharge and that predicted theoretically is known as the coefficient of discharge Cd : Cd actual disch arg e area of vena contracta x actual velocity there Cc x Cv ideal disch arg e area of orifice x ideal velocity Values of Cc and Cd quoted in text books lie between 0.60 and 0.65, and for Cv around 0.98. Note that if the orifice is placed in the side of the tank and is relatively large, then the predicted velocity can no longer be assumed to be constant across the jet and the discharge has to be calculated by integration. 45 Throat section u1 Q, u2 z2 z1 p2 p1 Reference level iii) Venturi meter: This device for measuring the flow rate through a pipe consists of a tapered throat placed within the pipe. Because the flow velocity at the reduced-diameter throat is greater than in the pipe upstream of the throat, there is also a change in pressure through the tapered section. Initially ignoring any frictional energy losses, Bernoulli's equation can be used to relate the measured pressure difference between an upstream section (1) and the throat (2): 2 2 p1 p2 Q Q + + z1 = + + z2 g 2gA1 2 g 2gA2 2 and hence: Qideal A1 2 g h 2 A1 1 A2 where h is the difference in piezometric head between section 1 and section 2, usually measured with a differential manometer. In practice, there is always some energy lost to friction and turbulence between 1 and 2 - and this results in p2 being slightly less than its "ideal" value. To overcome this, we introduce another coefficient of discharge Cd such that: Qactual Cd A1 2 g h 2 A1 1 A2 Cd A1 A2 A1 A2 2 2 2 g h Note that h is the head of fluid flowing through the pipe, and NOT the difference of head of manometer fluid. For many practical designs of venturimeter, a value of 0.98 is often used for Cd and, anyway, most commercial instruments will be provided with an empirical calibration depending on the exact geometry of the throat. 46 iv) Orifice meter: Another common technique for measuring flow rates along a pipeline is to install an "orifice plate". This consists of a plate with a sharp-edged hole concentric with the pipe. Tappings are provided upstream and downstream to allow measurement of the loss of flow "head" through the orifice. The downstream tapping is located to be as close as possible to the position of the vena contracta. The orifice diameter is usually less than 20% of the pipe diameter. Because of the sudden contraction of the flow through an orifice plate, the downstream flow is extremely turbulent - a sign that a significant proportion of the kinetic energy of the flow is being wasted. In fact, the useful "head loss" across an orifice plate is far greater than the equivalent loss across a venturimeter, and this may outweigh the cheapness when choosing an appropriate instrument. v) Weirs: patm δz u2 p1/ρg u1 z2 z1 b patm Front view of weir Section through weir For free surface flows it is not possible to use the devices mentioned above to measure discharge. Instead, various designs of weir can be installed - each with a particular relationship between depth of flow and volume flow rate. Here we consider flow over a sharp-edged weir or notch. To derive a theoretical relationship between the depth of flow over a weir and the volume flow rate, it is necessary to make a number of radical assumptions. For instance, the upstream velocity is assumed uniform across the whole flow cross-section, parallel to the channel bed, and negligible in comparison to the velocity over the weir; the upstream water surface is assumed 47 horizontal until directly above the weir plate; the pressure in the air under the downstream overflow (the nappe) is atmospheric; surface tension and viscosity are negligible. Then, taking datum level at the weir crest, Bernoulli's equation applied to a typical streamline simplifies from : 2 2 p1 u1 p u + + z1 = 2 + 2 + z 2 g 2g g 2g and, including the assumptions that p1 = patm +ρg(H-z1) , u1 =0 and p2 = patm , becomes: 2 u2 + z2 u2 2g (H z2 ) 2g It is then possible to deduce the total volume discharge over the weir by integrating strip by strip: p atm H p atm H Qideal bu2 dz2 0 H H b 2 g ( H z 2 ) dz2 b 2 g ( H z 2 ) 0 1 2 dz2 0 23 b 2 g ( H z 2 ) 23 b 2 g H 3 3 H 2 0 2 where b is the width of the weir/notch, and Q ideal is the theoretical discharge if no energy was lost to friction and all the assumptions made above were valid. Of course, in practice, this is not the case, and the actual discharge is found by multiplying by another empirical coefficient of discharge. Weirs come in many shapes and sizes, the V-notch weir being one of the most useful because it allows gauging of a wide range of flow rates [head varies as Q2/5 rather than as Q2/3 for a rectangular design]. Its coefficient of discharge is also less variable than for other designs. 48 CEGE1009 Mechanisms (Fluids): TUTORIAL SHEET 5 Water =1000 kg/m3; Air R = 287 J/(KgK), = 1.24 kg/m3 at STP; mercury = 13560 kg/m3 1. A horizontal pipe 350 mm in diameter carries a fluid for which = 0.95 A tapered section is to be incorporated in the pipe so as to provide a throat of reduced diameter at one point and the difference in pressure developed between static pressure holes at the throat and at a section upstream is to be used to operate a control system. To activate the control, a pressure difference greater than 24 kPa is required when the volume flow rate through the main pipe exceeds 0.15 m3 /s. Neglecting friction, calculate the throat diameter required. [Ans: 162 mm] 2. A venturi-meter has its axis vertical, the inlet and throat diameters being 150 mm and 75 mm respectively. The throat is 225 mm above the inlet, the coefficient of discharge is 0.96, and a liquid with = 0.78 flows through at a rate of 40 litres/s. Calculate (a) the pressure difference between inlet and throat; (b) the difference of level which would be registered by a vertical Utube manometer containing mercury, the tubes above the mercury being full of the liquid flowing through the venturi. [Ans: 34.24 kPa, 259.4 mm] 3. Show that the volume enclosed by a paraboloid of revolution height h, radius a, is half the volume of its circumscribing cylinder. A cylindrical tank 0.6 m in diameter and 1.2 m high is half filled with water. What speed of rotation about its vertical axis will cause water to reach the top? At what speed will the water depth at the wall be 0.9 m and how deep is it then at the centre? [Ans: 154 rev/min, 109 rev/min, 0.3 m] 4. In order to act as dust collector, a column of air is made to rotate as a forced vortex in a pipe 1 m in diameter with an angular velocity 10 s-1 . If the pressure at the wall is atmospheric, find the gauge pressure at the centre. [Ans: - 15.51 Pa] 5. A ventilating duct of square section with 200 mm sides, includes a 90 0 bend in which the centreline of the duct follows a circular arc of radius 300 mm. Assuming that frictional effects are negligible and that upstream of the bend the air flow is completely uniform, determine the way in which the velocity varies with radius in the bend. Find the mass flow rate when a water-filled Utube manometer connected between the mid-points of the outer and inner walls reads 11.5 mm. [qr = constant; 0.538 kg/s] 6. A cylindrical air-filled container is fitted with an impeller which, in the region 0 < r < b, drives the air round as a forced vortex at angular velocity , but allows the air in the region with b < r < R to move as a free vortex. A small hole in the centre of the upper cover plate communicates with the ambient air at atmospheric pressure. Derive expressions for the pressure distribution in the container, the pressure at the rim, and force on the upper plate. 7. Determine the head over a 600 V-notch weir when the discharge is 170 litres/s. [Take the coefficient of discharge as 0.60] 49