Test #1

advertisement

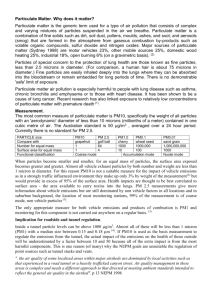

Name or Student # ______________________________ CHEE 481 Air Quality Management Test #1, Feb. 7, 2008 Notes: Open book test, the use of notes, books and calculators are permitted. Time for test is 60 minutes. Test consists of three (3) questions for a total of 20 marks – Question #1 is worth 5 marks, Question #2 is worth 5 marks and Question #3 is worth 10 marks Submit this test question sheet with your answer booklet Question #1 (5 marks) The graph shown in Figure 1 in this test paper displays the cumulative distribution for two types of particulate materials that might occur in industrial processes. These distributions are depicted by the straight lines, A and B, in this graph, presented as a log-normal cumulative distribution (cumulative mass % as a function of particle diameter). The data for the A distribution represents a size distribution that might arise from very small particulates associated with a combustion process. The B distribution is a size distribution for larger particles that might arise in a materials processing operation (mining, food industry, pulp & paper, cement, etc.). For each distribution, estimate the parameters , and the resulting form for the cumulative distribution function F(z): 1 1 erf(z / 2 ) 2 2 ln(x) - ln( ) Where z = ln( ) F(z) = Question #1 99 A Cumulative distribution, % 98 B 95 90 84 % 80 70 50 50% 30 20 16 % 10 5 2 1 0.5 0.01 0.1 1 10 100 Particle diameter, microns Figure 1. Cumulative distribution for two particulate samples depicted by the lines A and B. Question #2 (5 marks) In assignment #1 the particulate collection efficiency in the human respiratory system was depicted by the efficiency curves shown in Fig. 2. This behaviour is also typical of industrial capture systems and can be divided up into three regimes: Regime A – particles with dP < ~0.3 m where the capture efficiency increases with decreasing particle size, Regime B – particles in the range ~0.3 < dP < ~1 m where the capture efficiency is a minimum, and Regime C – particles with dP > ~ 1 m where the capture efficiency increases with particle size, reaching a constant value of ~100% for larger particles with dP > ~10 m. Describe briefly why the particulate capture efficiency typically follows this pattern for each regime. In your description point out what capture mechanisms contributes to the observed Particle capture efficiency, % efficiency. 100 80 A C 60 40 B 20 0 0.01 0.1 1 10 Particle size (dP), m Figure 2. Typical particulate capture efficiency in the human respiratory system and industrial capture processes as a function of particle diameter (diameter, dP). Question #3 (10 marks) A primary product in the cement industry is calcium oxide, CaO, obtained from the high temperature calcining of CaCO3. Normally the CaO is almost fully recovered however some product dust is also present in most calcining operations. Cement plants have particulate capture systems such as filters to remove this type of dust product from their air emission sources. A cement plant proposes to shut down the pollution control system for an 8-hour shift to perform necessary repairs on the unit. During this shutdown period, particulate emissions from the main emission stack for the plant are expected to occur. You have been asked to prepare an analysis of the potential impact of this emission source for the local Ministry of the Environment office prior to receiving approval for this proposed shut-down. The primary impact is expected to be a direct fall-out of the particulate in the local environment. The emitted particulate material is released through a stack causing particles to be directed downwind at a height of about 40 m above the ground. Particles can be assumed to acquire the local wind velocity UW 5 m/s in the horizontal direction and a velocity component equivalent to the particle terminal velocity in the vertical direction (no additional mixing occurs and g = 9.8 m/s2). Particles in the size range of dP = 2.5 – 200 m are expected to be released. Estimate the range of downwind distances, L, over which this particulate material might reach ground level. Assume that air has a density, F = 1.18 kg/m3, and viscosity, F = 1.85 10-5 kg/m-s. An MSDS summary sheet for CaO is given on the next page of this test paper showing some of the health risks of this material. This information also indicates that the specific gravity of CaO 3.34 (i.e. density of CaO is 3.34 g/cm3). In your calculations, you should apply the Cunningham correction factor assuming the mean free path for the air is 0.065 m. Also estimate the time required for these particles to reach their terminal velocity. W C aO pa r tci el s U px H = 40m U U C em en t P al n t L py Chemical Safety Data: Calcium oxide Common synonyms Quicklime, burnt lime Formula CaO Physical properties Form: White to light grey powdery solid Stability: Stable, but reacts with moisture and absorbs carbon dioxide from the air. Melting point: 2572 C Water solubility: reacts Specific gravity: 3.34 Principal hazards *** Contact with the eyes can cause serious irritation. *** The solid is corrosive, so is likely to be harmful if swallowed or inhaled. Safe handling Wear safety glasses. Minimize the amount of powder that gets into the air. Keep off the skin. Emergency Eye contact: Immediately flush the eye with plenty of water. If irritation persists, call for medical help. Skin contact: Wash off immediately with soap and water. If swallowed: Wash out the mouth with water if the person is conscious. Do not induce vomiting. If the quantity swallowed is significant call for medical help. Disposal Small amounts of calcium oxide may be disposed of with normal laboratory waste, unless local rules prohibit this. Protective equipment Safety glasses. Further information Calcium oxide Chemicals in the HSci database More extensive safety data