acp_measuring_probe_for_PartSens

advertisement

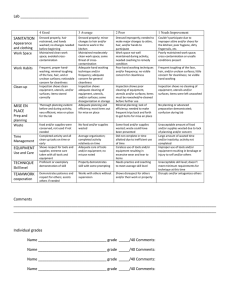

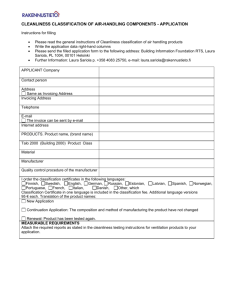

Press Release New Measuring Probe for PartSens Inspection System from acp Direct Inspection of Sheet Metal Blanks for Particulates, and Documentation With PartSens, acp GmbH makes it possible to directly measure and document particulate contamination on component surfaces for the first time ever. A new, enlarged measuring probe significantly expands the range of applications for this innovative inspection system, so that sheet metal blanks and auto body panels, for example, can be efficiently scrutinised for particulate cleanliness. The new PartSens measuring probe has a measuring surface of 20 x 15 mm and allows for efficient, random sample testing of component surfaces for particulate cleanliness. Inspecting sheet metal blanks before press forming in the field of auto body fabrication is a typical application for the new measuring system. A large US automobile manufacturer is already using the system to inspect auto body panels for cleanliness before they’re painted. Further applications include the monitoring of systems and production environments, and examining the degree of cleanliness achieved in the cleaning process. Particulate contamination with sizes of all the way down 25 µm can be detected. Measurements can be performed either manually, or by means of an automated process. Reliable under Difficult Conditions Thanks to Optical Filters The inspection system works with direct sidelighting in order to illuminate the surface to be inspected. Thanks to the integration of optical filters, the measuring probe generates extremely high contrast, thus assuring reliable inspection even under difficult conditions, for example structured surfaces. The measuring probe only needs to be passed over the surface under test in order to inspect it for particulate cleanliness. The sidelight image is visualised in real-time at an integrated screen, and the number of particles and their size are ascertained and displayed. Orientation, position and an outline of the particles is represented in a live image. This allows for reliable conclusions regarding the number, the size and the size distribution of the particles. Particle assignment and evaluation can be programmed in accordance with customer- specific requirements. Due to the fact that measurement results are available immediately, the user can react without delay to exceeded limit values, and expensive rework and scrap can be avoided. Simple Documentation of Measurement Results PartSens is equipped with an integrated thermal report printer for documentation of measurement results. Measured values and live images can also be saved to a USB memory stick with the help of the USB port at the front of the device for documentation and further processing at a PC. Caption acp – advanced clean production GmbH – has developed a new measuring probe for the PartSens inspection system. It has a measuring surface of 20 x 15 mm and is equipped with optical filters. This results in sidelight contrast which allows for precise, reliable measurement of particulate cleanliness even under difficult conditions, for example structured surfaces. Typical applications include the inspection of sheet metal blanks before press forming, for example in the field of auto body fabrication, as well as monitoring systems and production environments and examining the degree of cleanliness achieved in the cleaning process. --acp – advanced clean production GmbH acp – advanced clean production GmbH – was founded in Stuttgart in 1997. The company evolved out of the Fraunhofer Institute for Production Technology and Automation IPA. Today, acp is a supplier of state-of-the-art process technologies and products used for portable and stationary surface inspection and cleaning precision engineered surfaces, as well solutions for dosing viscous media. In the meantime, the inspection technologies product range of the company which is now located in Esslingen offers systems for direct particulate and structure detection, as well as the detection of contaminating films and particulates on precision engineered surfaces. The cleaning technologies product range includes above all CO2 based cleaning systems, by means of which high levels of cleanliness can be achieved economically. We would be grateful to receive a copy of any publication featuring content from this release. Contact persons for the editors: SCHULZ. PRESSE. TEXT. Doris Schulz Martin-Luther-Strasse 39 70825 Korntal, Germany Phone: +49 (0)711 854085 Fax: +49 (0)711 815895 ds@pressetextschulz.de www.schulzpressetext.de acp – advanced clean production GmbH Stefan Kaller Im Hasenlauf 2 75446 Wiernsheim, Germany Phone: +49 (0)7041 9600-0 Fax: +49 (0)7041 9600-27 mail@acp-micron.com www.acp-micron.com