Manufacture – all liquid coatings and inks

advertisement

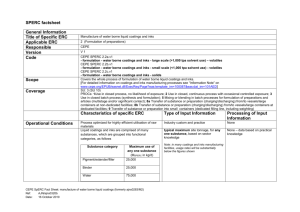

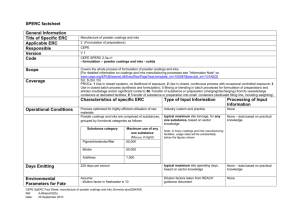

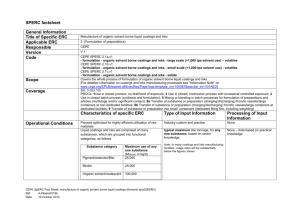

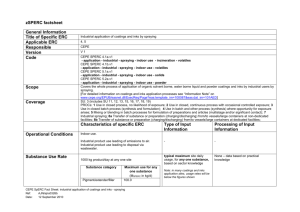

SPERC factsheet General Information Title of Specific ERC Applicable ERC Responsible Version Code Scope Coverage Operational Conditions Manufacture of organic solvent and water borne liquid coatings and inks Use only when CEPE SPERC 2.1a - c or CEPE SPERC 2.2a – 2.2c cannot be used in preference 2 (Formulation of preparations) CEPE V1 CEPE SPERC 2.4a.v1 - formulation - liquid coatings and inks (where specific formulation not known) - large scale(>1,000 tpa solvent use) - volatiles CEPE SPERC 2.4b.v1 - formulation - liquid coatings and inks (where specific formulation not known) - small scale (<1,000 tpa solvent use) - volatiles CEPE SPERC 2.4c.v1 - formulation - liquid coatings and inks (where specific formulation not known) - solids Covers the whole process of formulation of organic solvent borne and water borne liquid coatings and inks. [For detailed information on coatings and inks manufacturing processes see “Information Note” on www.cepe.org/EPUB/easnet.dll/ExecReq/Page?eas:template_im=100087&eas:dat_im=101AED] SU: 3 (SU 10) PROCs: 1Use in closed process, no likelihood of exposure; 2 Use in closed, continuous process with occasional controlled exposure; 3 Use in closed batch process (synthesis and formulation); 5 Mixing or blending in batch processes for formulation of preparations and articles (multistage and/or significant contact); 8a Transfer of substance or preparation (charging/discharging) from/to vessels/large containers at non-dedicated facilities; 8b Transfer of substance or preparation (charging/discharging) from/to vessels/large containers at dedicated facilities; 9 Transfer of substance or preparation into small containers (dedicated filling line, including weighting) Characteristics of specific ERC Type of Input Information Processing of Input Information Process optimized for highly efficient utilisation of raw materials Liquid coatings and inks are comprised of many substances, which are grouped into functional categories, as follows Industry custom and practice None typical maximum site tonnage, for any one substance, based on sector knowledge None – data based on practical knowledge Substance category Pigment/extender/filler Maximum use of any one substance (MSPERC in kg/d) 25,000 Binder 25,000 Water 75,000 CEPE SpERC Fact Sheet: manufacture of all liquid coatings (formerly ajns0285/M4) Ref: AJN/ajns0321b Date: 16 October 2010 Note: in many coatings and inks manufacturing facilities, usage rates will be substantially below the figures shown Organic solvent/coalescent 100,000 Additives 1,000 Days Emitting 225 days per annum typical maximum site operating days, based on sector knowledge None – data based on practical knowledge Environmental Parameters for Fate Calculation Assume: - dilution factor in freshwater is 10 - dilution factor in marine waters is 100 Dilution factors taken from REACH guidance document None Emission Fractions (from the process) Characteristics of Specific ERC a) Total volatile substances: To air Emissions to air of organic solvents from the manufacture of coatings and inks are regulated by the Solvent Emissions Directive (1999/13/EC). Emission fraction: - maximum 0.05 (< 1,000t/a organic solvent) - maximum 0.03 (> 1,000 t/a organic solvent) of total solvent tonnage inputs into a manufacturing site. Justification i) Emission limits from The Solvent Emissions Directive (1999/13/EC) [http://eurlex.europa.eu/LexUriServ/LexUri Serv.do?uri=OJ:L:1999:085:000 1:0022:EN:PDF and corrigendum] iii) EMISSION SCENARIO DOCUMENT ON COATINGS INDUSTRY (PAINTS, LACQUERS AND VARNISHES), OECD, July 2009 [http://www.oecd.org/officialdocu ments/displaydocumentpdf?cote =ENV/JM/MONO(2009)24&docla nguage=en] b) Individual organic solvents: Emissions of an individual volatile substance is dependent on: - the volatility of the substance - the extraction air speed - other technical measures to control releases to the air Emission fraction (maximum): CEPE SpERC Fact Sheet: manufacture of all liquid coatings (formerly ajns0285/M4) Ref: AJN/ajns0321b Date: 16 October 2010 i) CEPE expert decision based on EMISSION SCENARIO DOCUMENT ON COATINGS INDUSTRY (PAINTS, LACQUERS AND VARNISHES), OECD, July 2009 [http://www.oecd.org/officialdocu - solvent vapour pressure above 1,000 Pa (boiling point below 120°C): 0.036 - solvent vapour pressure below 1,000 Pa (boiling point above 120°C): 0.006 of the individual substance tonnage used per site ments/displaydocumentpdf?cote =ENV/JM/MONO(2009)24&docla nguage=en] c) Solid substances: i) EMISSION SCENARIO DOCUMENT ON COATINGS INDUSTRY (PAINTS, LACQUERS AND VARNISHES), OECD, July 2009 [http://www.oecd.org/officialdocu ments/displaydocumentpdf?cote =ENV/JM/MONO(2009)24&docla nguage=en] No direct dust emissions to the air are expected. Initial loss from handling of solid substances is captured by air extraction devices. Emission fraction maximum 0.000097 of the substance tonnage used per site. To Wastewater/ Sewer/ Water courses Emissions via equipment cleaning and subsequent discharge to wastewater. Release to wastewater is expected to be 0.005 of the substance volume used per site. Adoptd from the EMISSION SCENARIO DOCUMENT ON COATINGS INDUSTRY (PAINTS, LACQUERS AND VARNISHES), OECD, July 2009 [http://www.oecd.org/officialdocu ments/displaydocumentpdf?cote =ENV/JM/MONO(2009)24&docla nguage=en] To Soil Appropriate Risk Management Measures (RMM) that No emissions Not applicable Type of RMM Typical Efficiency Air On-site Technology CEPE SpERC Fact Sheet: manufacture of all liquid coatings (formerly ajns0285/M4) Ref: AJN/ajns0321b Date: 16 October 2010 VOCs may be used to achieve required emission reduction RMMs primarily are aimed at controlling emissions of VOCs at source, rather than at “end of pipe” to meet the relevant total emission limit value set out in section 17, Annex IIA,1999/13/EC (SED). A wide range of RMMs are used to minimise emissions to atmosphere: - use of closed storage facilities (e.g. bulk storage tanks, IBCs, drums) for VOC-containing raw materials - use of closed transfers of liquids from storage to production equipment (e.g. metered piped or pumped additions) - use of closed production equipment, with no extraction, except when opening vessels for additions/sampling etc - use of semi-closed production vessels with extraction to atmosphere to maintain workplace airborne VOC concentrations below respective OELs - use of impermeable covers on work in progress - use of closed filling equipment - use of closed equipment cleaning and use of non-organic solvent based cleaning fluids. - storage of finished products in closed containers (bulk tanks, IBCs, drums, cans etc) - recycling and reuse of overmake product in subsequent batches - storage of all VOC-containing wastes in closed, secure containers (bulk tanks, IBCs, drums) Efficiency of VOC RMMs As the SED VOC emission controls are focused on controlling global emissions from the manufacturing plant, the performance of individual RMMs is not relevant – the overall efficiency of the total manufacturing process (process steps + RMMs) is a minimum either 95% or 98%. Particulates RMMs are primarily aimed at controlling emissions of particulates at the most significant emission points to atmosphere from sources within the manufacturing process where airborne particulates can be created. Typically: - particulate raw materials are delivered in bulk tankers and discharged to closed silos - particulate raw materials are delivered in closed packaging (IBCs, drums, boxes, sacks) - closed transfers of particulates from storage to production equipment (e.g. metered piped or pumped additions) is used - no extraction is used on closed production equipment, when adding and incorporating particulate raw materials - use of semi-closed production vessels with extraction to atmosphere are used to maintain CEPE SpERC Fact Sheet: manufacture of all liquid coatings (formerly ajns0285/M4) Ref: AJN/ajns0321b Date: 16 October 2010 workplace airborne particulate concentrations below respective OELs - cyclone and bag filters, connected to (often multiple) emission sources, are used to control emissions from manufacturing plant - particulate wastes are stored in closed containers. Efficiency of particulate RMMs Bag and cyclone filters are typically rated at 99% efficient. Off-site Technology None Other None Water On-site Technology STP where required by local regulations to meet local discharge limits Off-site Technology Municipal STP Soil None required Narrative Description of, and justification for, specific ERC Description: The manufacture of liquid coatings and inks is a multi-stage batch process. The process is arranged to maximise the efficiency of use of input raw materials, through the highest conversion into formulated products. Process losses are reduced to the absolute minimum, through use of general and manufacturing plant extraction to maintain workplace concentrations of airborne VOCs and particulates below respective OELs; and through use of closed or covered manufacturing equipment, wherever possible, to minimise evaporative losses of VOCs. The composition of products and the overall process are such that there are no discharges of raw materials or products to waste-water or to soil from the manufacturing plant. Justification: The overall high efficiency of the coatings and inks manufacturing process is reflected in the low emission factors identified in independent assessments, such as that carried out by the UK’s Environment Protection Agency, as part of the development of an Emission Scenarios Document for the OECD. Safe Use Communication in eSDS The REACH registrant establishes a set of standard conditions of safe use for a substance in the formulation of a coating or ink by adopting the conditions specified in this SPERC and recommending a Required Removal Efficiency (RRE) for adequate risk reduction. This may include the removal efficiency of municipal sewage treatment plant (RESTP,SPERC), and the efficiency of an on-site emission reduction (REER,SPERC). This information is documented in the Chemical Safety Report and communicated in the extended Safety Data Sheet. CEPE SpERC Fact Sheet: manufacture of all liquid coatings (formerly ajns0285/M4) Ref: AJN/ajns0321b Date: 16 October 2010 All other parameters underlying a substance exposure scenario based on this SPERC are implicitly referred to via the reference to this SPERC. Scaling (emissions to waste water only) The formulators of organic solvent and water borne coatings and inks are responsible for evaluating the compliance of their specific situations with the registrant’s information. To that end, the users need to know their site-specific substance use rate (MSite) and days emitting (TEmission,Site), onsite and offsite emission controls and subsequent total substance emission reduction efficiency (RETotal,Site = 1 – [(1 – REOnsite,Site) x (1 – REOffsite,Site)]), sewage treatment plant effluent flow rate (GEffluent, Site) and receiving water dilution factor (qSite). Adequate control of risk exists if the following relevant expression holds true: for risk driven by wastewater treatment plant microbes [MSPERC x (1 – RETotal,SPERC )] / GEffluent,SPERC [MSite x (1 – RETotal;, Site)] / GEffluent,Site for risk driven by freshwater/freshwater sediments, marine water/marine water sediments [MSPERC x (1 – RETotal,SPERC )] / (GEffluent,SPERC x qSPERC ) [MSite x (1 – RETotal, Site)] / (GEffluent,Site x qSite) for risk driven by secondary poisoning (freshwater fish/marine top predator) or indirect exposure to humans (oral) [MSPERC x TEmission,SPERC x (1 – RETotal,SPERC )] / (GEffluent,SPERC x qSperc ) [MSite x TEmission,Site x (1 – RETotal, Site)] / (GEffluent,SPERC x qSite) It is simpler and thus may be preferable to some users to compare MSite with MSafe (the maximum tonnage that can be safely used, within the prescribed operating conditions, OC SPERC and RMM, RETotal,SPERC ). Adequate control of risk exists if the following conditions are met [RETotal ,Site RETotal,SPERC, GEffluent,Site, GEffluent,SPERC and qSite qSperc] and MSafe MSite. Local amount used, emission days per year, receiving water flow rate (or dilution factor), sewage treatment plant effluent flow rate, and risk management measure removal efficiency are the adjustable parameters for emission assessment. These parameters can be refined using site-specific information, which often is obtainable with limited effort and expertise. Adjusting the assessment by refining these parameters is referred to as scaling. Scaling is applied to evaluate compliance of a specific use with a generic Exposure Scenario. For that reason, site parameter values which deviate from the default values need to reflect the actual situation. This may have to be justified on demand. The release factors are an additional set of adjustable parameters; however, refining the default values requires significant justification and, thus, is beyond the boundary conditions defined in the SPERC Factsheet. For that reason, release factor refinements do not constitute a SPERC-based assessment and must be considered an element of downstream user chemical safety assessment. CEPE SpERC Fact Sheet: manufacture of all liquid coatings (formerly ajns0285/M4) Ref: AJN/ajns0321b Date: 16 October 2010