L2W-C

advertisement

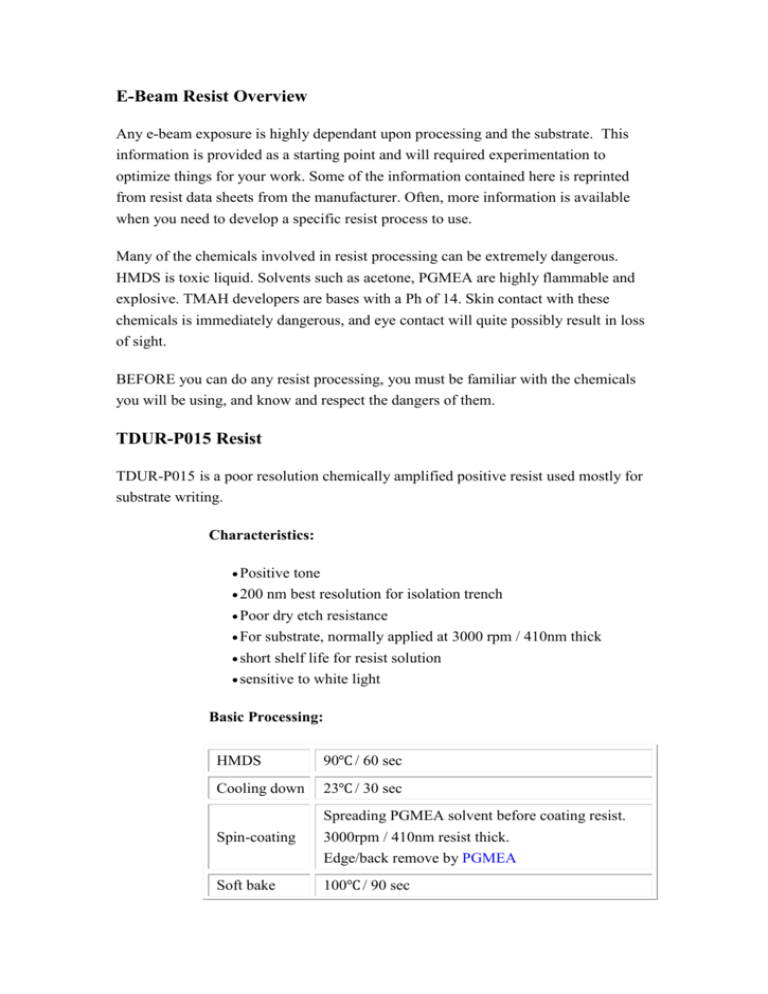

E-Beam Resist Overview Any e-beam exposure is highly dependant upon processing and the substrate. This information is provided as a starting point and will required experimentation to optimize things for your work. Some of the information contained here is reprinted from resist data sheets from the manufacturer. Often, more information is available when you need to develop a specific resist process to use. Many of the chemicals involved in resist processing can be extremely dangerous. HMDS is toxic liquid. Solvents such as acetone, PGMEA are highly flammable and explosive. TMAH developers are bases with a Ph of 14. Skin contact with these chemicals is immediately dangerous, and eye contact will quite possibly result in loss of sight. BEFORE you can do any resist processing, you must be familiar with the chemicals you will be using, and know and respect the dangers of them. TDUR-P015 Resist TDUR-P015 is a poor resolution chemically amplified positive resist used mostly for substrate writing. Characteristics: Positive tone 200 nm best resolution for isolation trench Poor dry etch resistance For substrate, normally applied at 3000 rpm / 410nm thick short shelf life for resist solution sensitive to white light Basic Processing: HMDS 90℃ / 60 sec Cooling down 23℃ / 30 sec Spin-coating Spreading PGMEA solvent before coating resist. 3000rpm / 410nm resist thick. Edge/back remove by PGMEA Soft bake 100℃ / 90 sec expose Dose around 50µC/cm² and 70µC/cm² for 200nm trench and hole at 40kev Post expose bake 120℃ / 90 sec Cooling down 23℃/ 30 sec developer E2-nozzle developer TMAH 2.38% / 60 sec dry Spin dry Hard bake 115℃/ 600 sec ADI CD-SEM All coating and developer process are programmed #2 and # 4 recipe by CLEAN TRACK, respectively. NEB22-A2 Resist High resolution chemically amplified negative resist with high sensitivity and contrast. Characteristics: negative tone 100 nm best resolution for isolation line For substrate, normally applied at 1120 rpm / 360nm thick long shelf life for resist solution not sensitive to white light Basic Processing: HMDS 90℃/ 60 sec Cooling down 23℃/ 30 sec Spin-coating Spreading PGMEA solvent before coating resist. 1120rpm / 360nm resist thick. Edge/back remove by PGMEA Soft bake 110℃ / 120 sec expose Dose around 7.2µC/cm² for 100nm isolated line at 40kev Post expose bake 105℃ / 120 sec Cooling down 23℃ / 30 sec developer E2-nozzle developer TMAH 2.38% / 60 sec dry Spin dry Hard bake 110℃ / 120 sec ADI CD-SEM (In-line SEM) All coating and developer process are programmed #1 and # 5 recipe by CLEAN TRACK, respectively.