Transmittance IR experiment

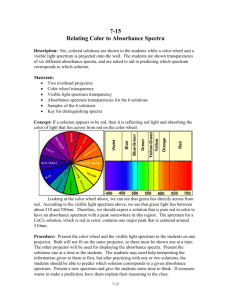

advertisement

Transmission IR Study for Supported Metal Catalysts prepared by Ilkeun Lee and Ricardo Morales October, 2006 Catalysts Synthesis The supported metal catalysts were prepared by wet impregnation. Aqueous solution of metal precursor is added to silica or alumina in appropriate amount to obtain metal weight loading for the oxide support. The resulting slurry solution is stirred at room temperature for a few hours before transferring them to a rotary evaporator, where the water is evaporated by heating in a water bath at about 70–80oC. The resulting fine powder is dried in air inside an oven at 400oC for 3 hours to obtain metal oxide powders. Set-up for Transmission IR Cell The powder catalyst (20–30 mg) is pressed into a self-supported disk (10 mm in diameter) by using a manual press (room 108, physical science building, ask Ricardo Morales for key). The catalyst disk is mounted on a sample holder held in the center of the infrared cell. The ends of the cell are sealed with NaCl windows, and the cell is connected to a closed circulation system. The background pressure inside the IR cell is 10-2–10-3 Torr. The temperature of the cell, monitored by a thermocouple placed in a thin tube close to the sample, could be controlled between -140 and 600oC by using a combination of liquid nitrogen cooling and electric heating. During the cooling of the samples that followed the pretreatment procedure, transmission IR spectra are recorded between 400oC and room temperature in about 10–50oC intervals. These spectra are taken as references for those recorded at the same temperatures during the reaction. The thickness of sample disk should be checked in the cell with the interferrogram amplitude. If it is too thick, IR absorption bands may be too weak and noisy. The gases are introduced after cooling to room temperature following the pretreatment, and the spectra are recorded both in the presence of the gas phase and after outgassing mostly at 10–50oC intervals while heating from room temperature to 250–400oC. This procedure enables probing the surface species after outgassing. Most of the spectra are for adsorbed species on the sample after outgassing and at temperatures where some important spectral changes are observed. Before the introduction of gases, the reference spectra are recorded for the pretreated catalysts at given temperatures. About 2–5 Torr of each organic molecule and of oxygen or hydrogen (depending of the type of study) are then introduced in the cell, which was then outgassed to a pressure of 10-2–10-3 Torr at a given temperature for 5–10 min. Once set to perform IR spectroscopic experiments, the supported metal catalyst disk was pre-activated according to what is reported in the literature. In the case of Pt/SiO 2, the disk is first heated in vacuum at 150oC for 30 minutes in order to eliminate the adsorbed water. The catalysts are than heated in hydrogen form 150oC to 350oC on the presence of 5 torr of H2. Once the final temperature is reached (350 oC), the catalyst was kept at that temperature for 3-4 hours at 200 torr of hydrogen. After that, the catalyst is heated again in vacuum for about 15 min to remove the remaining hydrogen from the surface. The sample is finally cooled down to room temperature before introducing the reactant gases. Transmittance IR Measurement To generate a transmittance spectrum of a supported catalyst, both a background spectrum, which is taken with the clean surface, and a sample spectrum, which is taken after adsorption (and sometimes reaction) of the molecules on the surface are needed. These background and sample scans are taken separately. The transmittance data are collected on the PC using the Bruker software called OPUS. Getting Started 1. 2. Start the OPUS program; click the short-cut icon of the OPUS program on desktop. Then OPUS the login window appears on the screen. Type "OPUS" in the password line for default operator. For details on the program, consult the manual. Select "Measure" and then "Measurement". After a few seconds the measurement set-up windows appear on the screen. Check the experimental parameters under "Advanced", "Optics", "Acquisition", "FT" and "Display". Determine the Sample Position for the FTIR. 1. 2. Move the sample to the IR compartment. Select "Measure", "Measurement", and "Check Signal" in the Measurement window. If everything is OK, the interferrogram is displayed on the screen. Check the amplitude and select ADC Count to see easily. Move the IR cell until a maximum value is obtained: Both ends meet the windows in the walls of the IR compartment. Insert polyethylene forms at the both sides to have IR beam paths purged by dry air. Background Spectrum 1. 2. 3. 4. 5. When the sample is clean (!!) at a certain temperature, take a background spectrum by selecting "Measurement", "Basic", and "Collect Background". The program displays a message in the bottom line high-lighted by a green color indicating that the data are being taken. When the message disappears, the measurement is done; and from this point on you can proceed with the experiments (e.g. cool the sample, introduce gases etc.) During the data acquisition the interferrogram cannot be seen on the check signal menu. After background scans are finished, the "Measurement" window remains on the screen. Go the “Background” and Click “Save Background” to save the spectrum. The Filename (####.0) is saved automatically on the hard drive and displayed on the left (Window List) of the screen. The file can be saved as other formats on the hard drive. Select "Save File As", then check the file name and path to be saved. If you want an ASCII file, in the "Mode" option on the Save Spectrum window, select "Data Point Table" before clicking the "Save" button. During the cooling of catalyst, take and save background spectra in about 10–50oC intervals. Once the temperature reaches the lowest temperature, introduce the gas into the cell for 5 min. After pumping the gases, remove liquid nitrogen reservoir or heat the cell. During the heating, take sample spectra at the given temperatures with the proper background spectra prepared during the cooling. Sample Spectrum 1. 2. 3. 4. Select “load background” and click any background spectrum. Type sample name and explanation exactly in the lines for sample name and sample form. (e.g. Sample Name: 1% Pt/SiO2; Sample Form: after CO dosing of 10 Torr for 5 min at -150oC) Take the sample data by selecting "Collect Sample" at the same temperature at which the background was measured and wait until the highlighted message disappears (see also previous paragraph). Select “load background” again, and click another background spectrum for the next experiment. NOTE 1: Make sure that the sample position in the sample scan is exactly the same as in the background scan: DO NOT TRY TO OPTIMIZE THE SAMPLE POSITION BETWEEN A BACKGROUND AND SAMPLE SCAN, even if the signal intensity is lower than it was in the background scan! Do not change any parameter between the background and sample scans. NOTE 2: Keep backups of the OPUS files and ASCII data. These files contain the actual data from which all other data can be easily derived. Training For the consistent and reliable data, the following trainings are strongly recommended for the beginner. After each level, the spectra should be checked by other person who is experienced Level 1. Sample Cleaning Transmission IR spectra after each step during the activation of a catalyst disk in vacuum. Level 2. Sampling Control Transmission IR spectra with a clean supported metal catalyst between -150 and 200oC, with 25oC or smaller interval. Level 3. Gas Manifold Control Transmission IR spectra of CO adsorbed on the catalyst between -150 and 100oC, with 25oC or smaller interval.