实验十九 粉体流动性的测定

advertisement

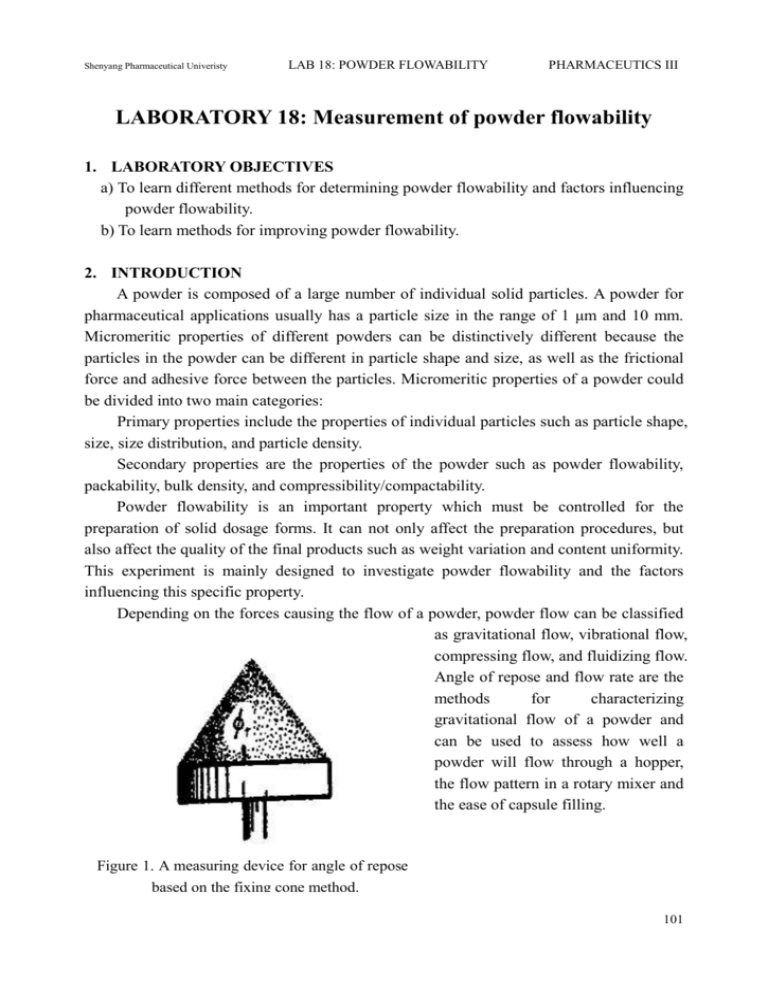

Shenyang Pharmaceutical Univeristy LAB 18: POWDER FLOWABILITY PHARMACEUTICS III LABORATORY 18: Measurement of powder flowability 1. LABORATORY OBJECTIVES a) To learn different methods for determining powder flowability and factors influencing powder flowability. b) To learn methods for improving powder flowability. 2. INTRODUCTION A powder is composed of a large number of individual solid particles. A powder for pharmaceutical applications usually has a particle size in the range of 1 μm and 10 mm. Micromeritic properties of different powders can be distinctively different because the particles in the powder can be different in particle shape and size, as well as the frictional force and adhesive force between the particles. Micromeritic properties of a powder could be divided into two main categories: Primary properties include the properties of individual particles such as particle shape, size, size distribution, and particle density. Secondary properties are the properties of the powder such as powder flowability, packability, bulk density, and compressibility/compactability. Powder flowability is an important property which must be controlled for the preparation of solid dosage forms. It can not only affect the preparation procedures, but also affect the quality of the final products such as weight variation and content uniformity. This experiment is mainly designed to investigate powder flowability and the factors influencing this specific property. Depending on the forces causing the flow of a powder, powder flow can be classified as gravitational flow, vibrational flow, compressing flow, and fluidizing flow. Angle of repose and flow rate are the methods for characterizing gravitational flow of a powder and can be used to assess how well a powder will flow through a hopper, the flow pattern in a rotary mixer and the ease of capsule filling. Figure 1. A measuring device for angle of repose based on the fixing cone method. 101 LAB 18: POWDER FLOWABILITY Shenyang Pharmaceutical Univeristy PHARMACEUTICS III Angle of repose is the maximum angle formed between a horizontal plane and the slope of a powder pile under a statically balanced condition. The angle of repose can be measured by the fixing funnel method, the fixing conical bottom method, the sloping box method, the evacuation method, and the rotating cylinder method. The fixing cone method (also named the residual cone method) is the most commonly used method for measuring the angle of repose of a powder as shown in Figure 1. With the buffering action from the two funnels on top of each other, the powders will fall onto the center of a round plate with a specific diameter. The powder flows down from the funnel and forms a cone. When the powder starts filling over the edge of the round plate, stop pouring the powder and measure the angle of repose formed between the slope of the cone and the plate. Flow rate of a powder is determined by measuring the time required for a specified Figure 2. Measuring device for flow quantity of powder flowing out of a funnel with rate measurement. a specific orifice. If the powder flowability is poor and the powder fails to produce a constant flow from the funnel, some glass spheres with a size of 100 μm in diameter can be added to facilitate powder flow. Measure the minimum number of glass beads needed for the powder to flow; the larger amount of glass beads needed, the poorer is the flowability of the powder. The measuring device is shown in Figure 2. Compressibility (压缩度) of a powder represents powder flow properties under vibrational conditions and can be used to assess the powder performance under different processing conditions in a vibrational mode such as compounding, sieving, and filling. The tapping device is shown in Figure 3. Compressibility is calculated by using the following equation: C f 0 100% f where, ρf —final tapped density, ρ0 —initial bulk density. Practically, the flowability of a powder is judged to be good when the compressibility is less than 20% ,whereas a poor powder flowability is indicated when the compressibility value is about 40%~50%. 102 Shenyang Pharmaceutical Univeristy LAB 18: POWDER FLOWABILITY PHARMACEUTICS III Figure 3. Tapping device 量筒 固定螺丝 计数器 刻度 measuring cylinder Fixing screw counter scale 电机 操作按钮 电源 Electrical motor Switch Power source 3. METHODS 3.1 Measurement of angle of repose 3.1.1 Materials Microcrystalline cellulose (MCC) powder, MCC spherical particle, lactose, talc, aerosil, and magnesium stearate. 3.1.2. Sample preparation a) Weigh 20 g of MCC powder and MCC spherical particle respectively. Measure the angle of repose and compare the effect of shape and size of the particles on the angle of repose. b) Weigh three different portions of 15 g MCC powder (or lactose) and mix each portion with 1% talc, 1% aerosol and 1% magnesium stearate, respectively. After mixing by using the geometric dilution method, measure the angle of repose of each sample. The lubricating efficiency of different lubricants can be compared based on the angle of repose obtained for the samples. c) Weigh 25 g of MCC powder and divide the powder into 5 parts with 0.2%, 1%, 2%, 5%, 10% talc added to samples respectively. After mixing, measure the angle of repose and compare the effect of glidant concentration on the flowability of the powder. Construct a graph with the angle of repose as the Y-axis and amount of 103 Shenyang Pharmaceutical Univeristy LAB 18: POWDER FLOWABILITY PHARMACEUTICS III glidant as the X-axis. 3.1.3 Measurement procedures Make sure that the powder falls onto the center of the round plate slowly and evenly, resulting in the formation of a pile of powder in a cone shape. When the powder starts to fall freely over the edge of the round plate, measure the angle of repose by a conimeter or calculate the angle of repose using the equation, tanθ=h/r with the measurement of the radius of the round plate (r) and the height (h) of powder cone pile. 3.2 Measurement of flow rate 3.2.1 Materials MCC powder, MCC spheres, and starch. 3.2.2 Sample preparation a) Weigh 15g of MCC powder, MCC spheres, and corn starch respectively. Measure their flow rate and determine the effect of particle shape and size on the flow rate of different samples. b) Glass beads with a size of 100 μm are mixed with the MCC powder or starch to improve powder flow. Compare the number of glass beads added to achieve the same flow rate. 3.2.3 Measurement procedures Test materials are loaded into the device for flow rate measurement (or a triangle funnel), open the outlet of the bottom funnel and measure the time for all the material flowing out from the device. 3.3 Measurement of compressibility 3.3.1 Materials MCC powder, MCC spheres, and starch 3.3.2. Sample preparation Weigh 15 g of MCC powder, MCC beads, and starch, respectively and measure the compressibility of these samples to compare the vibrational flowability of different materials with different particle shapes and sizes. 3.3.3 Measurement procedures Accurately weigh different test materials and add each material into the cylinder gently, measure the volume, and calculate the initial bulk density. Start the tapping machine until the volume of the material is not changing. Measure the final volume and calculate the 104 Shenyang Pharmaceutical Univeristy LAB 18: POWDER FLOWABILITY PHARMACEUTICS III tapped density. Compressibility is calculated using the equation shown above. 4. RESULTS AND DISCUSSION 4.1 Examine the particle size and shape of the powder under microscope and determine the effects of these two variables on powder flowability. 4.2 Determine the influence of glidant type and amount on powder flowability. 4.3 Determine the difference in flowability for different materials. 4.4 What is the main cause for the different flowabilities determined for different materials? 5. QUESTIONS a) How can the particle size and shape affect powder flowability? b) Why will a glidant reduce the powder flowability when an excessive amount is added? c) Which glidant is the most effective and why? References [1] M.J.Rhodes, Principles of powder technology, John Wiley and Sons, Chichester-New York, 1995. [2] D.Chulia, M.Deleuil,Y. Pourcelot. Powder technology and pharmaceutical processes, Elservier, Amsterdam-London, 1994. [3] Gran Alderborn, Christer Nystrm. Phamaceutical powder compaction technology.Marcel Dekker,Inc., New York·Basel,1995. (Fude CUI) 105