3.2 Diffraction and Quasi-Elastic Scattering Techniques

advertisement

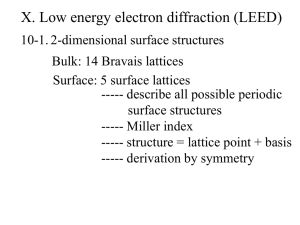

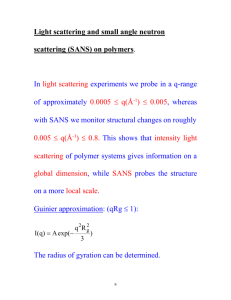

Lecture notes by John A. Venables. Latest version 1 March 2005 © Arizona Board of Regents for Arizona State University and John A. Venables 3.2 Diffraction and Quasi-Elastic Scattering Techniques a) LEED The common electron-based diffraction techniques are LEED and RHEED. As with all surface diffraction techniques, the analysis is based in terms of the surface reciprocal lattice. An important aspect of diffraction from 2D structures is that k// is conserved to within a surface reciprocal lattice vector G//, whereas k is not, as shown in diagram 62 (Luth). This leads to the idea of reciprocal lattice rods, a concept which takes a little while to absorb. The equipment for both diffraction techniques is simple, involving a fluorescent screen, with energy filtering in addition in the case of LEED, as indicated in diagram 63, to remove inelastically scattered electrons. There are three types of LEED apparatus in regular use. The 'Normal-view' arrangement has the LEED gun and screen mounted on a UHV flange, typically 8 inch (200 mm) across, and the pattern is viewed past the sample, which therefore has to be reasonably small, or it will obscure the view. Most new systems are of the 'Reverse-view' type, where the gun has been miniaturised, and the pattern is viewed through a transmission screen and a viewport. This enables larger sample holders to be used, which helps for such operations as heating, cooling, straining, etc. The third, and potentially most powerful technique is where, in addition to viewing the screen, the LEED beams can be scanned over a fine detector using electrostatic deflectors and focussing, in order to examine the spot profiles, which can be sensitive to surface steps and other forms of disorder at surfaces. This technique, which has been perfected by the Hannover group (M. Henzler et al.), is now known as SPA-LEED, emphasising the capability for Spot Profile Analysis. This would be a suitable topic for a seminar talk. There are two aspects to diffraction techniques. The first, and simplest, is that the positions of the spots give the symmetry and size of the unit mesh, i.e the surface unit cell. This can be seen dramatically in diagram 64, which shows LEED patterns of Si(111) in the high T '1x1' phase (a), the 7x7 reconstruction at two different electron energies and exposures (b and c) and the 'root-3' structure associated with the ML phase of Ag/Si(111) (d). These patterns are strikingly different in a qualitative sense. The most common use of electron diffraction techniques is primarily, often solely, in this sense. The second, and much more subtle effect, is that the positions of atoms in the mesh is not determined by this qualitative pattern (see diagrams 28-30, and the discussion in Section 1.4), but requires a quantitative analysis of LEED intensities. The difference between LEED and X-ray structure analysis is that a kinematic diffraction theory has limited usefulness, because the scattering is very strong. The dynamic theory is quite complicated, and has attracted some very high-powered theorists over the years. Application of the dynamic theory has so far 'solved' some 400 surface structures. This is impressive, but it pales besides the number of bulk structures solved by X-rays, using (developments of) kinematic theory. We can go into the elements of dynamic theory, which is constantly developing, at a later stage. For now, realise that the intensities are typically collected in the form of so-called I-V or I(E) curves, where the size of the Ewald sphere is varied by varying the probe energy (say from 20-150 eV), and the intensity data is obtained by 'tracking' along an individual reciprocal lattice rod. Various computer-controlled, and frame-grabbing, schemes have been developed to do this. The data base of solved structures was referred to already in section 1.4 (P.R. Watson et al, Atlas of Surface Structures, vols 1A and 1B, ACS Publications). A description of experimental and theoretical methods is given by Clarke. Luth, Chap. 4. is a good starting point for LEED, and Chap. 4.4 gives an overall introduction to the physics of multiple scattering (brave attempt). b) RHEED and THEED Because ASU is well known for its work in Electron Microscopy and Diffraction, many of us have met dynamical theory at higher electron energies in the context of the interpretation of TEM images. The physics is very similar in LEED, but the language used is a bit different. The language of RHEED is very similar to that which may be familiar to you from THEED. The discussion can again be separated into Geometry and Intensities. As seen in diagram 67, the glancing angle geometry of RHEED means that the reciprocal lattice rods are closely parallel to the Ewald Sphere near the origin. This means that the low angle region often consists of streaks, rather than spots (diagram 68). This part of the pattern corresponds to the Zero order Laue Zone (ZOLZ) in THEED patterns. The higher angle parts of a RHEED pattern are then equivalent to Higher order (HOLZ) rings in THEED patterns. The apparatus for RHEED can consist of a simple 5-20kV electrostatically focussed gun, for example to monitor the surface crystallography in an MBE experiment, where the glancing angle geometry has many practical advantages over LEED, especially in the ease of access around the sample. Or it can utilise an electron gun approaching electron microscope quality, and produce finely focussed diffraction spots over a wide angular range. Several workers have perfected this technique in Japan, an example of Si(111)7x7 being shown in diagram 69, with more examples in the books (e.g. Luth, Panel 8, fig 5, page 207). Again the question of intensities is much more detailed, involving multiple scattering and inelastic processes, and there is a large amount of discussion/ assertions about whether streaks or spots constitute evidence for good (i.e. well prepared, flat) surfaces. We leave this to seminar material, but make some general remarks in the next section. c) Elastic, Quasi-Elastic and Inelastic Scattering The theory of LEED and RHEED concentrates on elastic scattering, where the energy of the outgoing electron is the same as that of the incoming electron. But experimentally we cannot discriminate in energy very well in a typical diffraction apparatus. LEED grids/ screens are able to remove plasma loss electrons (~ 10-20 eV loss), but the intensities measured include phonon scattering (~ 25 meV losses and gains). This is thermal diffuse scattering, and is accounted for in the theories using a Debye-Waller factor, as in standard X-ray theory. At higher T, the intensities in the Bragg peaks fall off exponentially, as I/I0 = exp -(K2<u2>/2), with <u2> = 3h2T/(42mkd2), d being the Debye Temperature, and K the scattering vector (diagram 62a). Woodruff and Delchar give this formula, Chap 2, with k = K. This means that intensity measurements as a function of T measure <u2>, and several such studies have been done with LEED; examples are given by Prutton (Chap 5, pages 139-142, beware typographic errors in eqn 5.1). An interesting feature of such experiments is that the value of <u2> decreases towards the bulk value as the incident energy is increased, reflecting the increased sampling depth of the electrons. In a typical RHEED setup, there is no energy filtering, other than that caused by the fact that higher energy electrons produce more light from phosphor screens. Yet the geometry is such that plasmons, especially surface plasmons, will be produced very efficiently. Because plasmon excitation produces only a small angular deflection of the high energy beam, the diffraction pattern is not unduly degraded, but we should remember that they are present in the experiment, if not in the interpretation. A few groups have studied energy-filtered RHEED, but it has proven quite difficult to construct adequate filters which work over a large angular range. The basic reason for the surface sensitivity of LEED is the short inelastic mean free path for the excitation of plasmons (and other forms of electron-electron collision); this means that information from deeper in the crystal is effectively filtered out. One of the few calculations which we could usefully do in class (but there may not be time) is the pseudo-kinematic case, where one has single scattering and exponential attenuation. This calculation shows that the attenuation causes only a few layers at the surface to be sampled, which give rise to modulated reciprocal lattice rods, the width of the modulations being inversely proportional to the imfp. In the full dynamical LEED calculations, this attentuation effect is included by an imaginary potential, V0i. This is similar to the high energy case of RHEED and THEED, but the language is a little different. In particular, in TEM, we use imaginary potentials (V0i and Vgi) to describe contrast in images caused by inelastic scattering; but these are dependent on the aperture size used, and are typically due to the scattering of phonons and defects. In contrast to plasmons, these scattering effects cause a wide angular spread, and very little energy loss. LEED (especially SPA-LEED) and RHEED, and the corresponding microscopies (LEEM and REM) have been shown to be very sensitive to the presence of surface steps and other types of defects, including domain structures. Some of these sensitivities are due to the extra diffraction spots associated with particular domains; some of them are due to exploiting the difference between in-phase and out-of-phase scattering (see diagram 62b); some again depend on the small rotations produced by surface steps, and the increase in diffuse scattering. There are new techniques emerging, such as DLEED (Diffuse-LEED) and 'Electron Holgraphy'. An examination and discussion of some of these factors/ techniques would be a suitable seminar topic. The above discussion has concerned the effect of inelastic processes on the interpretation of elastic scattering processes. In the next two sections we are concerned with the understanding and use of the inelastic processes in their own right.