Milling time effect on release kinetics from co-ground drug

advertisement

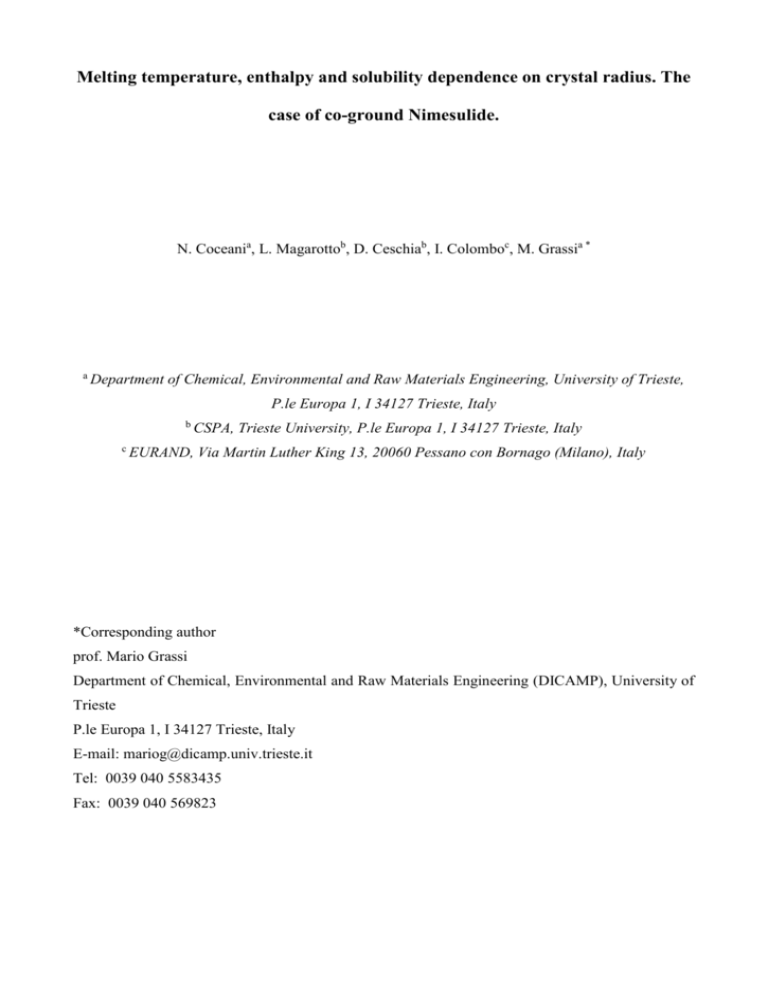

Melting temperature, enthalpy and solubility dependence on crystal radius. The case of co-ground Nimesulide. N. Coceania, L. Magarottob, D. Ceschiab, I. Colomboc, M. Grassia * a Department of Chemical, Environmental and Raw Materials Engineering, University of Trieste, P.le Europa 1, I 34127 Trieste, Italy b c CSPA, Trieste University, P.le Europa 1, I 34127 Trieste, Italy EURAND, Via Martin Luther King 13, 20060 Pessano con Bornago (Milano), Italy *Corresponding author prof. Mario Grassi Department of Chemical, Environmental and Raw Materials Engineering (DICAMP), University of Trieste P.le Europa 1, I 34127 Trieste, Italy E-mail: mariog@dicamp.univ.trieste.it Tel: 0039 040 5583435 Fax: 0039 040 569823 Abstract Aim of this paper was to determine the variation of melting enthalpy, temperature and solubility of organic solids in relation to the curvature radius of the crystalline phase (thought, for the sake of simplicity, of spherical shape). In particular, the attention was focussed on the nanocrystals formed following co-grinding of a non steroidal anti-inflammatory drug (nimesulide) and an amphiphylic polymer (polyvinylpyrrolidone) acting as nano-crystals stabiliser. To pursue our target, three mathematical models were developed: one for modelling the melting enthalpy-temperature variation with nano-crystals radius, one for the estimation of solubility variation with nano-crystals radius and the last to describe drug release from co-ground systems. This study allowed the determination of the nanocrystals fraction and size distribution in the co-ground systems, drug solubility increase due to the comminution process up to the nano-scale range and the estimation of amorphous drug solubility. On the basis of this study we could conclude that, in the case of nimesulide, significant reduction of the nanocrystals melting enthalpy/temperature and an interesting increase of the nanocrystals solubility occur for crystal radii lower than 8 nm. Keywords: melting enthalpy, melting temperature, solubility, nano-crystals, mathematical model. 2 1. Introduction It is well known that the solubility, melting temperature and enthalpy of organic solid nano-crystals depend on crystal radius (assumed, for the sake of simplicity, of spherical shape) [1]. In particular, crystal radius decrease reflects in melting temperature/enthalpy decrease and in solubility increase. The physical explanation of these phenomena should rely on the different behaviour of surface and bulk atoms. Indeed, as surface atoms have fewer inter-atomic bonds with respect to bulk ones, they would be characterized by higher energy contents. Accordingly, lattice break-down in correspondence of crystal surface would require less energy and would be favoured with respect to bulk lattice break-down. This interpretation is supported by the recent work of Huang and coworkers [2]. These authors, on the basis of experimental data and molecular dynamics simulations, found clear differences in the structural dynamics of nano-crystals surface and bulk atoms. In particular they found that coherent diffraction patterns recorded from individual nanocrystals are very sensitive to the atomic structure of nanocrystal surfaces. Obviously, the effect of surface atoms becomes relevant (i.e, appreciable at the macroscopic level) only when the number of surface atoms is not negligible compared to that of the bulk atoms and this happens when crystal surface/volume ratio becomes very high. This usually takes place for crystals radii falling in the nanometer range. It is important to underline that, usually, commercial organic solids are not characterised by a perfect crystalline structure but they are produced in form of microparticles (secondary grains) constituted by an ensemble of crystals (primary grains) bound together by amorphous connecting phase. In addition, primary grains are constituted by coherent crystalline domains (crystallites) whose radius is to be intended as nanocrystal radius. If the temperature/enthalpy decrease with crystal radius has been experimentally proved and modelled by many researchers [1, 3], solubility increase with crystal radius is more controversy as its experimental determination is very difficult. Indeed, 1) finely divided crystals possessing lattice defects (amorphous regions) cannot be used for experimental tests, as their surface characteristics can be changed by manufacturing processes [4] 2) small amounts of impurities can substantially change the solubility and 3) polydisperse crystalline systems are affected by Ostwald ripening [5]. This phenomenon consists in larger crystals growth at the expense of smaller particles and the asymptotic reduction of solution solubility. Indeed, the dissolution of small crystals, characterised by higher solubility, renders the liquid phase over-saturated with respect to big crystals, characterised by lower solubility. Thus, part of the solute leaves the solution and provokes bigger crystals growth. As a consequence, the models proposed to the mathematical interpretation of this phenomenon gave rise to a big debate among researchers [6]. Undoubtedly, however, the extreme relevance of nano-crystals solubility enhancement, reflecting in drug bioavailability enhancement [7], encouraged researchers to continue studying this nano3 crystals peculiarity as demonstrated, for example, in a recent review on this topic [8]. In addition, despite the problems connected to the theoretical study of nano-crystals increased solubility, the realisation of stable nano-crystals delivery systems is not so cumbersome. For example, solvent swelling [9, 10], supercritical carbon dioxide [11, 12] and co-grinding [13, 14] allow to get a drug dispersion, in form of very small crystals ranging from the nanoscale to the virtual zero-dimension corresponding to the drug amorphous state [9], inside a carrier (usually an amorphous crosslinked polymer) aimed to stabilise for years the unstable nano-crystals. Interestingly, these delivery systems are very reliable and effective as proved by in vitro and in vivo tests led on animals and humans [8]. Indeed they can considerably improve the bioavailability of poorly water soluble but permeable drug [15] (class II drugs according to the Amidon classification [7]). Aim of this paper was to theoretically and experimentally study the temperature/enthalpy reduction and the water solubility increase of a poor water soluble anti-inflammatory drug dispersed in a polymeric crosslinked matrix by means of co-grinding. Different co-grinding times were considered in order to follow the time evolution of the original macrocrystals (Xcr), nanocrystals (Xncr), and amorphous drug fraction (Xa), nanocrystals size distribution and average nanocrystals water solubility. At this purpose, the co-ground systems were characterised by means of differential scanning calorimeter (DSC), powder X-rays diffraction (PXRD), particle size distribution (PSD) and in vitro release tests (IVRT). A proper mathematical model was developed to deduce Xcr, Xncr, Xa, the nanocrystals size distribution and melting temperature/enthalpy resorting to DSC data. Drug nanocrystals solubility was determined according to a thermodynamic mathematical model based on the knowledge of nanocrystals melting temperature/enthalpy. Instead, amorphous drug solubility was determined interpreting in vitro release tests by a mathematical model accounting for system surface area, drug solubility, drug dissolution, amorphous drug recrystallisation and Xcr, Xncr, Xa. Crosslinked polyvinylpyrrolidone (PVP Cl-M) and nimesulide were chosen, respectively, as polymeric carrier and model drug. Indeed, while PVP Cl-M, due to its amphiphylic nature, proved to be a good stabilizing carrier for small organic lipophylic drugs [15] nimesulide is a typical class II drug (according to Amidon classification [7]) showing poor water solubility and satisfactory permeability [16, 17]. Moreover, both PVP Cl-M and nimesulide are commonly used in the pharmaceutical field. 2. Materials and methods Crosslinked polyvinylpyrrolidone (C6H9NO, PVP Cl-M, BASF, Germany, pharmaceutical grade), obtained by popcorn polymerisation in form of a white, tasteless, odourless and water insoluble powder was used as carrier. Nimesulide (HELSINN, Pambio Noranco, CH), a typical NSAID (Non Steroidal Anti Inflammatory Drug), was considered as model drug for its low water solubility. 4 Nimesulide solubility in water was measured by adding an excess drug amount in a known solvent volume under gentle stirring in thermostatic conditions (24 hours). Then, liquid samples were withdrawn, filtered and drug concentration was measured by means of a UV spectrophotometer (Lambda 6/PECSS System, Perkin-Elmer Corp., Norwalk, CT, wavelength 393.4 nm). The resulting solubility was 9 ± 1 g/cm3 (37 °C). Nimesulide/PVP Cl-M physical mixtures (ratio 1:3 (w/w)) were co-ground for 0.5, 1, 2 and 4 hours in a planetary mill (Pulverisette 7, Fritsch GmbH, D)) setting the rotational speed to 350 rpm. Mill vials, made up by agate, contained seven agate balls (1 cm diameter) plus 0.375 g nimesulide and 1.125 g PVP Cl-M each. The planetary mill was chosen as it is efficient and its dynamic behaviour, jointly with the energy transfer to co-ground materials, is well understood [18]. For each co-ground system, particle size distribution and particles surface area in swollen conditions were determined by means of Laser Light Scattering technique (MALVERN UK). Indeed, due to the rapid PVP Cl-M swelling kinetics in water, we could assume that drug release takes place from completely swollen particles [10]. Pure nimesulide, different co-ground systems and drug-polymer physical mixture were characterised by means of a X-rays diffractometer equipped with a Cu Ka source (40KV, 20 mA) (Stoe 500, Siemens, Germany) in order to exclude possible nimesulide polymorphs formation due to co-grinding. Finally, Thermal analysis were carried out with a power-compensated differential scanning calorimeter DSC 7 by Perkin Elmer (Norwalk, CT) in order to determine the drug fraction, in form of original macrocrystal (Xcr), nanocrystal (Xncr), amorphous state (Xa) and nanocrystals size distribution, on the same systems. The samples to be analyzed by DSC were put into aluminium pans (6-7 mg of nanocomposite and about 2 mg of raw drug) and then scanned under a N2 stream of 20 cm3/min 0 °C/min. Temperature calibration was made, at the same heating rate, using Hg and In as standards. Release tests, performed in duplicate, were led in 600 cm3 water (Vr) at 37°C. At time zero, 200 mg of physical mixture (nimesulide and PVP Cl-M, in a 1:3 weight ratio, simply mixed) or co-ground system (nimesulide and PVP Cl-M, weight ratio 1:3, mixed and then subjected to co-grinding) were added to the release environment. Uniformity conditions were ensured by means of an impeller (rotational speed 250 rpm). The use of a fiber optic apparatus (HELLMA, Italy), connected to a spectrophotometer (ZEISS, Germany, wavelength 393.4 nm), allowed the determination of nimesulide concentration without perturbing the release environment (each release test lasted 20 minutes). Moreover, this methodology allowed to easily overcome the problem connected to drug concentration measurement in presence of a dispersion of solid particles. Indeed, while the maximum nimesulide absorption occurred at 393.4 nm, the scattering effect due to polimeric particles uniformly occurred at every wavelength. Accordingly, the real absorbance related to 5 nimesulide concentration was the difference between the absorbance measured at 393.4 nm and that measured at 500 nm (at 500 nm nimesulide did not absorb). In order to study nimesulide recrystallisation process, non sink conditions were attained in release environment. 3. Theoretical 3.1 Nanocrystals fraction and size distribution Fundamental prerequisite for the estimation of Xcr, Xncr, Xa and for the evaluation of the nanocrystals size distribution characterising co-ground systems is the determination of nanocrystals melting temperature (Tmr) and specific enthalpy (hmr) dependence on nanocrystals radius Rnc. Brun and coworkers [1], starting from the Laplace and Gibbs-Duhem equations, found the following relations between melting temperature and nanocrystals radius: γ hmr dT 2 slnc T ρs R Tm Tmr Tmr Tm hmr 2 dT nc T R (1) γ sl 1 1 ρ γ lv ρ ρ l s s (2) where Tm is the infinite radius crystal melting temperature, lv and sl are, respectively, liquid drugvapour and solid drug-liquid drug surface tensions while s and l are, respectively, solid and liquid drug density. Eq.(1) is based on the hypothesis that the liquid-vapour curvature radius (Rlv) is infinite, this happening when the crystal is embedded in a large amount of amorphous drug. Thus, crystal melting occurs inside a large amount of liquid phase. On the contrary, eq.(2) relies on the hypothesis that Rlv is coincident with Rnc, this occurring when many crystals are packed together and, upon melting, each crystal is surrounded by a thin liquid film. Thus, while eq.(1) applies for low nanocrystals fractions (Xncr ≈ 0), eq.(2) holds in the opposite case (Xncr ≈ 1). As in real systems nanocrystals can undergo melting in both the above mentioned conditions, a reasonable way accounting for this mixed condition is weighing the contribute of eqs.(1) and (2) right hand side terms according to Xncr as follows: γ sl 1 1 γ sl hmr 2 d T X γ 1 X ncr lv ncr nc T T ρs R ρs ρl ρs m Tmr (3) It is clear that eq.(3) reduces to eq.(1) or to eq.(2) when Xncr = 0 or 1, respectively. In order to get eq.(3) solution, the knowledge of the dependence of nanocrystals specific melting enthalpy (hmr) on nanocrystals melting temperature (Tmr) and radius (Rnc) is needed. For its simplicity and theoretical strength, the equation of Zhang and co-workers [3] was adopted: hmr hm 3 R nc γ sv γ lv m Cp dT ρ l Tmr ρs T (4) 6 where hm∞ is the specific melting enthalpy referred to the infinite radius drug crystal, Cp is the difference between the liquid and the solid drug specific heat capacity at constant pressure. As Cp is almost temperature invariant, the third term on the right hand side of eq.(4) can be approximated by Cp(Tm∞ - Tmr) without relevant errors. The determination of hmr(Rnc), Tmr(Rnc) and Xncr is achieved by means of an iterative, numerical, simultaneous solution of eqs.(3)-(4). The iterative procedure starts assuming a first attempt value for Xncr and then numerically solving eqs.(3)-(4) to have a first evaluation of the functions hmr(Rnc), Tmr(Rnc). Then, Xncr is recalculated according to: hcg Tmr , ω d X ncr hmix Tm , ω d ω d hr hT (5) where hcg is the experimentally determined co-ground system melting enthalpy referred to the system unit mass (drug plus polymer) and evaluated at Tmr (as our carrier, the polymer, is amorphous, hcg is only due to drug melting), d is the drug mass fraction characterising both the physical mixture and the co-ground systemhmix is the physical mixture melting enthalpy referred to the mixture (drug plus polymer) unit mass and evaluated at Tm∞ and d, hr and hT are the specific enthalpy corrections (referred to pure drug unit mass) representing the nanocrystals melting enthalpy reduction due to nanocrystal radius reduction and melting temperature reduction (see, respectively, the second and third term in the right hand side of eq.(4)). hr and hT are determined in the simultaneous solution of eqs.(3)-(4). If the relative difference (Rd) between Xncr value calculated according to eq.(5) and that initially assumed as first attempt is less then a fixed threshold value (Tol), the iterative procedure is stopped and eqs.(3)-(5) provides hmr(Rnc), Tmr(Rnc) and Xncr respectively. On the opposite, the procedure is repeated assuming as new value for Xncr the following one: old new 1 λ λX ncr X ncr X ncr (6) old new where is the relaxation parameter ranging between 0 and 1, X ncr and X ncr represent, respectively the Xncr value assumed at the beginning of the ith iteration loop and that recalculated according to eq.(5) at the end of the ith iteration loop. The procedure is repeated up to Rd < Tol. Obviously, the determination of Xcr simply requires the evaluation of: X cr hcg Tm , ω d hmix Tm , ω d (7) where hcg(Tm∞,d) is the experimentally determined co-ground system melting enthalpy referred to the system unit mass (drug plus polymer) and evaluated at Tm∞. Xa is finally determined as: X a 1 X cr X ncr (8) 7 Once hmr(Rnc), Tmr(Rnc) and Xncr are known, it is possible evaluating nanocrystals size distribution. Starting point is the relation among the volume dVr occupied by nanocrystals of radius lying in the range Rnc – (Rnc + dRnc) and their specific melting enthalpy (J/Kg) hmr, melting enthalpy (J) Hmr and density : dVr d H mr hmr (9) From eq.(9) we have: dVr dH mr 1 dH mr dTmr 1 nc nc nc dR dR hmr dTmr dR hmr dT dH mr dt dTmr 1 Q 1 mr nc nc dt dTmr dR hmr v dR hmr Q 1 (10) v where t is time, Q is the signal registered by DSC (mW) and v is the DSC heating speed (°C/min). Eq.(10) allows the determination of the nanocrystals differential volume distribution (dVr/dRnc) as Q , v, hmr(Rnc) are known and the function dTmr/dRnc can be numerically determined as the function Tmr(Rnc) was previously determined. Of course, it is more convenient defining the nanocrystals differential volume distribution according to: f R nc nc Rmax nc Rmax dVr dR nc dVr dR nc nc dR (11) nc nc where Rmax and Rmin represent, respectively, the maximum and minimum value assumed by Rnc. 3.2 Drug solubility In order to evaluate the solubility dependence on nanocrystals radius Rnc, recourse was made to the classical thermodynamic approach ruling the equilibrium between a liquid phase (our solvent) and a nano-crystalline solid phase (our drug) [19]. Assuming that only the solid component partitions between the two phases (this means that the liquid component does not go in the solid phase), the equilibrium condition requires that the drug fugacity in the solid phase f ds equates the drug fugacity in the liquid phase f dl . By definition we have: f γ d X d f f ds f ds l d l d (12) 8 where d and Xd are, respectively, the drug activity coefficient and solubility (molar fraction) in the liquid phase, f dl is the drug fugacity in the reference state while f ds is the drug fugacity in the solid state. Accordingly, drug solubility in the liquid phase will be given by: Xd f ds 1 f dl γ d (13) Assuming f dl as the fugacity of pure drug in the state of under-cooled liquid at the system temperature (T) and pressure (P), the ratio f ds f dl can be evaluated according to: G41 RT ln f dl f ds (14) where R is universal gas constant and G41 represents the variation of the molar Gibbs free energy between the state of under-cooled liquid drug (state 4) and solid (nanocrystalline) drug (state 1) (see fig.1). G41 H 41 TS 41 1 4 Solid drug nanocrystals Under-cooled liquid drug T, P T, P isobaric heating H 21 Tmr T s s cp dT cp Tmr T H 43 cpl dT cpl T Tmr T S 21 Tmr T Tmr cps T T dT c ln Tmr T S 43 s p Tmr cpl T dT cpl ln T Tmr isobaric cooling 2 Solid drug nanocrystals Tmr, P Isobaric-isotermic melting H 32 hmr S 32 hmr Tmr 3 Liquid drug Tmr, P Figure 1 G41 can be conveniently evaluated according to the thermodynamic cycle reported in fig. 1. The solid nano-crystals at T and P represent state 1. While state 2 is given by nano-crystals heated, at constant pressure (P), up to their melting temperature Tmr, state 3 represents the completely melted nano-crystals at Tmr and P. Finally, state 4 is achieved by cooling up to T, at constant pressure (P), the liquid drug (under-cooled liquid). Accordingly, it follows: G41 H 41 TS 41 H 21 H 32 H 43 T S 21 S 32 S 43 (15) 9 where H ij and Sij are, respectively, the variation of the molar enthalpy and entropy between state “j” and “i”. In details, we have: H 21 Tmr c dT c T s p s p mr T S 21 T Tmr T H 32 hmr cps T dT cps ln Tmr T [as dP =0] S 32 hmr Tmr T H 43 c dT c T Tmr l p l p T S 43 Tmr Tmr cpl T [as g mr hmr smr 0 ] dT cpl ln T Tmr [as dP =0] (16) (17) (18) where cps and cpl are, respectively, the solid and liquid specific heat at constant pressure while gmr and smr are, respectively, the nano-crystals melting Gibbs free energy and entropy. Rearranging eqs.(14)-(18), drug solubility can be expressed as a function of determinable parameters: 1 Xd γd T Tmr cp R h exp mr RT T 1 Tmr cp Tmr 1 T R (19) where cp = cps - cpl . For what follows, it is more convenient expressing nanocrystals solubility Xd in terms of mass/volume: CsN Xd Md ρs 1- Xd Ms (20) where Md and Ms are, respectively, drug and solvent molecular weight while s is solvent density. 3.3 Release kinetics Although drug release from polymeric powders is a complex process influenced by many aspects such as polymer swelling, drug diffusion and dissolution [20], when drug dissolution is the rate determining step, the description of the whole process can be extremely simplified. This condition is usually met in the case of small polymeric particles carrying the drug mainly in their outer part [21]. Consequently, the most important step of the overall release process is represented by drug dissolution. In order to account for the simultaneous presence of amorphous and nanocrystalline drug on particles surface, we assume that the surface fraction of each particle occupied by nanocrystalline drug is proportional to nanocrystalline drug content, Xncr. Obviously, the remaining part of particle surface, proportional to (1 - Xncr), will be occupied by amorphous drug (in our system no infinite radius drug crystals were found, as later on shown) (see fig. 2). In order to complete the release model, the last important aspect to deal with consists in the re-crystallisation of the amorphous drug made unstable by the presence of the release medium. This, basically, implies amorphous drug solubility (Cs) reduction as nicely observed and modelled by Nogami and coworkers [22]. Assuming a first order kinetics, they got: Cs t Csa e -k r t Csnc 1 e -k r t (21) 10 where Csa is the initial amorphous drug solubility, Csnc is the nano-crystalline drug solubility and kr is the re-crystallisation constant. Although in the original Nogami model Csnc is the solubility of the infinite radius drug crystal, we replaced it with that of nanocrystals as nanocrystals conversion into infinite radius crystal is much slower than amorphous re-crystallisation. Thus, the effect of nanocrystals conversion into infinite radius crystals would be detectable only in very long lasting release experiments. Accordingly, drug concentration (Cr) increase in the release environment volume Vr can be given by the following equation Vr N dCr D 4πRi2 N pi X ncr Csnc Cr 4πRi2 N pi 1 X ncr Cs t Cr dt δm i 1 kd D δm (22) where t is time, Ri is the radius on the ith class of particles into which the ensemble of particles can be subdivided in, Npi is the number of particles belonging to the ith class, D is the drug diffusion coefficient in the stagnant layer (of thickness m) surrounding the generic particle (see fig. 2), kd is the dissolution constant and Cs is the amorphous drug solubility in the release environment. Csnc C r Drug nanocrystals m Polymeric core Cs Cr Stagnant layer Rp Amorphous Drug Figure 2 N It is worth noticing that as kd is retained equal for all the particles classes, 4πR i 1 2 i N pi is equal to the particles ensemble surface area given by the product of the particles mass (mp) times particles specific surface area (A). Accordingly, eq.(22) can be re-written as: Vr dC r mp Akd X ncr Csnc C r 1 X ncr Cs t C r dt (22’) Combining eqs.(21) and (22’) and adopting usual solution techniques [23], model solution reads: Cr t e -k r t e -α k d t α kα k1 Xk d d ncr C sa Csnc Csnc 1 e -αkd t (23) r 11 α A mp (24) Vr It is worthwhile noticing that eq.(23) holds until the drug is present on the surface of all particles. Afterward, A would be time dependent and the shown solution would be no longer valid. Nevertheless, we did not experience this condition in our release tests. 4. Results and discussion Figure 3 shows the comparison between the PXRD diffraction patterns relative to the physical mixture and the same mixture after two hours co-grinding. It is possible to notice that no substantial shifting of the typical nimesulide diffraction peaks (namely those at 2 = 5, 11, 12, 18, 19.5, 21, 22, 23, 24.3) occurs. As analogue diffraction patterns can be obtained for the other co-grinding times, namely 0.5, 1 and 4 hours, we can affirm that no polymorphs were generated because of grinding. 300 physical mixture 250 I (-) 200 150 100 50 2h co-ground system 0 4 8 12 16 20 2(deg) 24 28 Figure 3 Figure 4 shows that pure nimesulide melting takes place at 148.7 °C and melting enthalpy hm∞ is equal to 109000 J/Kg. The same figure reports the thermograms relative to two co-ground systems (0.5 hours, grey thick line; 1 hour, grey thin line). While in the first case melting temperature Tmr is equal to 129.6 °C and co-ground system melting enthalpy hcg is equal to 8700 J/Kg, in the second case (1 hour) melting temperature Tmr is equal to 126.6 °C and co-ground system melting enthalpy hcg is equal to 8500 J/Kg. This figure evidences how, practically, 0.5 hours are sufficient to completely destroy the original macrocrystals into nanocrystals. 12 T mr = 148.7 °C h m = 109000 J/Kg nimesulide T mr = 126.6 °C h cg = 8500 J/Kg 4.6 4.4 1 hour 35 30 25 4.2 4 3.8 20 15 3.6 3.4 10 0.5 hours 5 T mr = 129.6 °C; h cg = 8700 J/Kg 3.2 3 Heat flow (mW) Heat flow (mW) 5 4.8 0 100 110 120 130 140 150 T (°C) Figure 4 Similarly, figure 5 shows the thermograms relative to the other two co-ground systems studied in this work (2 hours, grey thick line; 4 hour, grey thin line). 35 T mr = 148.7 °C h m = 109000 J/Kg nimesulide 3.9 Heat flow (mW) 3.8 2 hours 3.7 3.6 Tmr = 118.0 °C h cg = 5100 J/Kg 3.5 20 4 hours 3.3 3.1 25 15 3.4 3.2 30 10 T mr = 112.0 °C h cg = 2500 J/Kg Heat flow (mW) 4 5 3 0 100 110 120 130 140 150 T (°C) Figure 5 The 2 hours thermogram shows a melting event occurring at 118 °C characterised by a melting enthalpy hcg equal to 5100 J/Kg while the 4 hours thermogram is characterised by a melting peak positioned at 112 °C with a melting enthalpy hcg equal to 2500 J/Kg. In order to evaluate nanocrystals fraction (Xncr) and size distribution (f) in the four co-ground systems, eqs.(3)–(7) and eqs.(10)-(11), respectively, are numerically solved knowing that [24] sl = 1.31*10-3 J/m2, sv = 13 57.57*10-3 J/m2, lv = 44.26*10-3 J/m2, s = 1490 kg/m3, s = 1343 Kg/m3 and cp = 333 J/Kg°C. Figure 6, reporting the result of the numerical solution, evidences how Xncr decreases with grinding time even if no differences, in terms of Xncr, are detectable for what concerns the 0.5 h and the 1h systems. Interestingly, however, these systems differs for the lower dimension of nanocrystal competing to the 1h system as witnessed by the left shifting of the nanocrystals size distribution peak. 2 X ncr[4h] = 0.14 ± 0.03 1.8 nc f (R )(1/nm) 1.6 1.4 X ncr[2h] = 0.33 ± 0.01 1.2 1 X ncr[1h] = 0.40 ± 0.01 0.8 0.6 X ncr[0.5h] = 0.40 ± 0.01 0.4 0.2 0 1 2 3 R nc(nm) 4 5 Figure 6 Thus, in this case, the increased energy provided to the co-ground mixture does not reflect in Xncr reduction but in nanocrystals radius (Rnc) reduction. Further increase of the grinding time comports both Xncr and nanocrystals radius reduction. In addition, higher grinding times reflect in a progressive narrowing of the nanocrystals size distribution as clearly visible in Figure 6. It is worth noticing that, for our systems, nanocrystals radius spans from about 1.4 nm and 4.5 nm. Figure 7A shows the hmr trend for Xncr = 1, 0 and 0.4. It can be seen that, at constant nanocrystals radius, Xncr decrease reflects in a more pronounced hmr reduction. In addition, it is interesting noticing that hmr zeroes in the range 0.415 nm ≤ Rnc ≤ 0.532 nm for 0 nm ≤ Xncr ≤ 1, respectively. As nimesulide unit cell radius (thought of spherical shape) is 0.435 nm [20], this result is absolutely reasonable and proves the correctness of our theoretical approach for the evaluation of hmr(Rnc). Figure 7B shows the hmr and Tmr decrease with Xncr for the particular case of Rnc = 1nm. When Xncr approaches 1, melting process occurs in presence of a small amount of (drug) liquid phase coating each nanocrystal. On the contrary, melting process occurs in presence of a wide amount of (drug) liquid phase for Xncr approaching 0. 14 120000 150 T mr [X ncr = 0.4] 100 80000 50 h mr Xncr = 1[X ncr = 1] h [X0.4ncr = 0.4] Xncr mr= h Xncr 0 ncr = 0] mr=[X 60000 40000 0 T mr (°C) h mr (KJ/g) 100000 -50 20000 0 -100 0.1 1 10 100 R nc(nm) Figure 7A 100 76000 74000 72000 80 70000 68000 h mr (J/Kg) T mr (°C) 90 70 66000 60 64000 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 X ncr(-) Figure 7B Once nanocrystals thermal properties have been determined, the nanocrystals solubility dependence on Rnc can be evaluated. To fulfil this aim, the determination of nimesulide activity coefficient (d) in water at 37°C was needed. Knowing the nimesulide molar solubility in water at 37°C, (Xd = 5.285*10-7 mol/l), melting enthalpy, melting temperature and cp (= 333 J/Kg), eq.(19) yields d = 115572. Assuming that d does not sensibly depends on concentration (at least for concentrations > 9 g/cm3), eq.(19) allows the estimation of nanocrystals solubility dependence on Rnc as shown in Figure 8 where the trend of the ratio CsN/CsN∞, for three different values of Xncr. (1, 0.4, 0), is reported. 15 C sN /C sN∞ 100 Xncr = 0 Xncr = 0.4 Xncr = 1 O-F equation 10 1 0.1 1 10 100 nc R (nm) Figure 8 We can see that nimesulide nanocrystals solubility CsN increases with reducing Rnc and that Xncr lowering implies CsN increase (at constant Rnc). While significant CsN increase takes place for Rnc < 8 nm, the maximum value of the ratio CsN/CsN∞ occurs for Rnc approaching nimesulide unit cell radius (0.435 nm). In this case, the ratio CsN/CsN∞ grows up to, approximately, 50. It is now worth comparing eq.(19) to the well known Ostwald-Freundlich equation [25, 26]: 2γ sl ν N CsN exp N nc CsN RT R (25) where γ slN is solid nimesulide/ water surface tension (3.2*10-2 J/m2 [24]) and N is the nimesulide molar volume (2.07*10-4 m3/mol). Figure 8, reporting eq.(25) trend, shows how this equation overestimates the ratio CsN/CsN∞ with respect to eq.(19), whatever Xncr considered. Interestingly, if eq.(25) exponent is multiplied by 0.4, eq.(25) coincides with eq.(19) calculated for Xncr = 0. When Xncr = 1, the same coincidence is found multiplying eq.(25) exponent by 0.285. Accordingly, we can conclude that if eq.(25) reliable predicts the qualitative CsN/CsN∞ trend, it fails in the quantitative prediction. In order to complete the analysis on nimesulide nanocrystals, we need to estimate amorphous nimesulide solubility (CsA) in water at 37°C. At this purpose it is necessary considering the experimental nimesulide release kinetics shown in Figure 9. In this figure, the increase of the release environment nimesulide concentration Cr versus time t for the physical PVP ClM/nimesulide mixture (open circles) and for the co-ground systems (open diamonds, 0.h cogrinding; filled triangles, 1 h co-grinding; open squares, 2h co-grinding; filled circles, 4 h cogrinding). It is clear that, whatever the co-ground system considered, the release kinetics is neatly 16 higher than that relative to the polymer/drug mixture where nimesulide is present only as infinite radius crystals. 25 3 C r( g/cm ) 20 15 0h 0.5 h 10 1h 2h 5 4h model 0 0 5 10 15 20 25 t (min) Figure 9 Moreover, release kinetics increases with increasing co-grinding time tm, to get the fastest release in the 2 h case. On the opposite, despite its highest amorphous content (Xcr = 0, Xncr = 0.14, Xa = 0.86) the 4h sample shows a slower release kinetics, just in between those relative to the 0.5h and 1 h coground systems. This behaviour can be explained remembering that release kinetics is essentially ruled by the amorphous/nanocristalline drug fraction (proportional to drug solubility and, consequently, to drug dissolution rate) and co-ground system size distribution (or surface area). The 4h system can not immediately exploit its potentiality in terms of release kinetics because it is constituted by bigger particles in comparison to those of the other co-ground systems as clearly indicated in figure 10. While 0.5 h co-grinding (open diamonds) reflects in a shifting of particles size distribution towards smaller diameters with respect to the not ground system (open circles), for longer co-grinding time tm the opposite behaviour is observed. This means that co-grinding promotes two different and counteracting mechanisms. The first consists in particles comminution, while the second leads to particles aggregation. While the first mechanism is obvious, the second one could be explained remembering that in the grinding media collision zones, temperature can easily exceed polymer rubbery transition temperature [27]. Accordingly, this condition, coupled with the mechanical energy supplied by the collision, would allow the establishment of links between polymeric chains belonging to different particles. This, in turn, determines particles aggregation. Moreover, it is not surprisingly that particle aggregation prevails for longer times. Indeed, it is reasonable that aggregation process is enhanced by mill temperature that increases with time as experimentally observed [28]. 17 120 2 0 h (PVP ClM) A = 0.8 m /g 2 0.5 h A = 2.7 m /g 1 h A = 1.8 m2 /g 2 h A = 1.6 m2 /g 2 4 h A = 0.9 m /g Cumulative % 100 80 60 40 20 0 0.1 1 10 D (m) 100 1000 Figure 10 When no significant differences in particle size distribution occur, release kinetics is essentially ruled by the amorphous drug fraction as witnessed by release kinetics competing to the 0.5h, 1h and 2h co-ground systems (see Figure 9). The strategy adopted to estimate amorphous nimesulide solubility CsA consists in the simultaneous fitting of eq.(23) on release data referring to the four coground systems considered (see Figure 9). Thus, 13 model fitting parameters need to be determined (CsA, four nanocrystals solubility Cnc05h, Cnc1h, Cnc2h, Cnc4h, and four couples kd - kr (one for each coground system)). Unfortunately, however, the high correlation of model parameters makes their simultaneous determination impossible. This is the reason why nimesulide nanocrystals solubility are fixed on the basis of eq.(19) (Cnc05h = 18.8 g/cm3, Cnc1h = 20.2 g/cm3, Cnc2h = 24.0 g/cm3, Cnc4h = 27.3 g/cm3) and model fitting parameters are reduced to 9. Although, theoretically, kd and kr should be equal for all systems, in the light of model approximations, we let them vary from system to system. Model fixed parameters are (= 0.09, 0.061, 0.053, 0.029 m-1, for the 0.5h, 1h, 2h and 4h co-ground systems, respectively). Figure 9 shows the satisfactory agreement between model best fitting (solid lines) and experimental data (symbols). This statement is statistically supported by the high F test value reported in Table 1. The same table, reporting all the model fitting parameters, indicates that CsA = 4251 ± 377 g/cm3, this leading to CsA/Cs∞ = 472. An inspection of Figure 8 evidences the reasonability of this estimation and underlines a discontinuity between the solubility competing to the smallest nanocrystal (whatever Xncr) and the solubility of the amorphous phase. It is also interesting noticing that kd and kr values, although variable from system to system (if model hypotheses were perfectly accomplished, they should be equal for all the co-ground systems), are not too far from each other and assume the smallest value in the 4h system 18 case. This result can be interpreted in the light of the above mentioned particle aggregation phenomenon. Indeed, it is reasonable that particle aggregation implies part of the drug to be trapped among the particles so that, in these clusters, drug is present both on the surface and in the inner part. This implies that drug release does not depend only on dissolution but also on diffusion through polymeric meshes. Accordingly, it is reasonable that our mathematical model interprets this situation by means of kd decrease, this being and indicator of increased release resistance. Similarly, kr reduction indicates a slower release process. 5. Conclusions In this work the attention was focussed on studying the relation among organic nanocrystals melting temperature, enthalpy and solubility. In particular, this relation was studied for crystals radii ranging from infinite to that of the crystal unit cell. For its importance in the pharmaceutical field as controlled release system, the formation of drug nanocrystals in co-ground drug-polymer systems was considered. An iterative procedure aimed to determine nanocrystal fraction and size distribution in the co-ground system was developed. The same procedure allowed determining nanocrystals melting temperature and enthalpy dependence on nanocrystal radius. In the particular case studied (nimesulide) we found that appreciable reduction of melting temperature and enthalpy occurs for radii ≤ 8 nm. On the basis of this thermal information, it was possible developing an equilibrium thermodynamic model for the determination of nanocrystals solubility in relation to nanocrystals radius. Also in this case, appreciable solubility increase occurred for radii ≤ 8 nm. Interestingly, the comparison of this model with the well-known Ostwald-Freundlich one allowed verifying that Ostwald-Freundlich model yields to qualitative correct results even if it fails in the quantitative description. Nevertheless, small corrections to the Ostwald-Freundlich model get the two models almost coincident. Finally, the estimation of drug amorphous solubility was determined resorting to a mathematical model developed to interpret in vitro drug release from different coground drug-polymer systems. Model fitting assumed nanocrystals solubility estimated on the basis of the developed equilibrium thermodynamic model. Data fitting yielded to a reasonable value of the amorphous drug solubility. Interestingly, we found that the increase of the co-grinding time implied the reduction of nanocrystals fraction and radius. At the same time, for the highest cogrinding time considered (4 h), it clearly promoted co-ground system particles aggregation. This reflected in slower release kinetics despite the highest amorphous drug content. . 19 References 1) M. Brun, A. Lallemand, J. F. Quinson, C. Eyraud, 1973. J. De Chimie Physique 70 (1973) 979. 2) W. J. Huang, R. Sun, J. Tao, L. D. Menard, R. G. Nuzzo, J. M. Zuo, 2008. Nature Materials 7 (2008) 308. 3) M. Zhang, M. Y. Efremov, F. Schiettekatte, E. A. Olson, A. T. Kwan, S. L. Lai, T. Wisleder, J. E. Greene, L. H. Allen, Physical Review B 62 (2000) 10548. 4) M. Mosharraf, C. Nyström, Drug Dev. Ind. Pharm. 29 (2003) 603. 5) G. Madras, B. J. McCoy, Crys. Gro. Des. 3 (2003) 981. 6) G. Buckton, A. E. Beezer, Int. J. Pharm. 82 (1992) R7. 7) G. L. Amidon, H. Lennernäs, V. P. Shah, J. R. Crison, Pharm Res 12 (1995) 413. 8) I. Colombo, G. Grassi, M. Grassi, J. Pharm. Sci. 98 (2009) 3961. 9) F. Carli, I. Colombo, L. Magarotto, C. Torricelli, Int. J. Pharm. 33 (1986) 115. 10) M. Grassi, I. Colombo, R. Lapasin, J. Contr. Rel. 68 (2000) 97. 11) P. G. Debenedetti, J. W. Tom, S. D. Yeo, G. B. Lim, J. Control. Rel. 24 (1992) 27. 12) I. Kikic, M. Lora, A. Cortesi, P. Sist, Fluid Phase Equilibria 158-160 (1999) 913. 13) M. Grassi, I. Colombo, F. Carli, R. Lapasin, Eur. J. Pharm. Sci. 6 (1998) 260. 14) D. Voinovich, B. Perissutti, M. Grassi, N. Passerini, A. Bigotto, J. Pharm. Sci. 98 (2009) 4119. 15) F. Meriani, N. Coceani, C. Sirotti, D. Voinovich, M. Grassi, 2004. J. Pharm. Sci. 93 (2004) 540. 16) R. Davis, R. N. Brogden. Drugs 48 (1994) 431. 17) G. Cignarella, P. Vianello, F. Berti, G. Rossoni, Eur. J.Med. Chem. 31 (1996) 359. 18) N. Burgio, A. Iasonna, M. Magini, S. Martelli, F. Padella F. 1991. Il Nuovo Cimento 13 (1991) 459. 19) J. M. Prausnitz, R. N. Lichtenthaler, E. G. Azevedo, Molecular Thermodynamics of Fluid-Phase Equilibria, Prentice Hall, Englewood Cliffs, N.J., 1999, 3rd ed. 20 20) M. Grassi, G. Grassi, R. Lapasin, I. Colombo, Understanding drug release and absorption mechanisms: a physical and mathematical approach, CRC Press, Taylor & Francis Group, Boca Raton, USA, 2007. 21) P. Bergese, I. Alessandro, I. Colombo, N. Coceani, L. E. Depero, 2005. Composites: Part A 36 (2005) 443. 22) H. Nogami, T. Nagai, T. Youtsuyanagi, Chem. Pharm. Bull. 17 (1969) 499. 23) B. Demidovic, Zadaci i upraznenija po matematiceskomy analizu, Mir edition, Moscow, 1975. 24) I. De Simone, Graduate thesis, Department of Pharmaceutical Sciences, University of Trieste, 2003. 25) H. Freundlich, in: E. P. Dutton and Company Inc., Colloid and Capillary Chemistry, 1923, p. 153. 26) W. Ostwald, Z. Phys. Chem., 34 (1900) 495. 27) A. Tonejc, A. M. Tonejc, D. Duzevic, Scr. Metall. Mater. 25 (1991) 1111. 28) J. M. Castillo, R. Lapasin, M. Grassi, Industrial & Engineering Chemistry Research, 42 (2003) 2015. 21 Captions to figures. Figure 1. Thermodynamic cycle used to estimate the variation of the molar Gibbs free energy ( G41 ) between the state of under-cooled liquid drug (state 4) and solid (nanocrystalline) drug (state 1). T is absolute temperature, P is pressure, Tmr is nanocrystals melting temperature while H ij and Sij are, respectively, the variation of the molar enthalpy and entropy between state “j” and “i”. Figure 2. Schematic representation of the drug loaded polymeric particles. While particle inner part (grey zone) is basically drug free, the drug disposes on the outer part of the particle. The drug can be present in the amorphous state (black zone) or as nanocrystals (dashed zone). A stagnant layer of thickness m surrounds the particle and concurs to determine drug dissolution constant kd. At the stagnant layer/solid drug interface, concentration is assumed equal to the time dependent drug solubility Cs, in the case of the amorphous drug while it is set equal to Cnc in the case of drug nanocrystals. Cr indicates drug concentration in the release environment. Figure 3. Comparison between the PXRD pattern relative to the PVP ClM/nimesulide (3/1, w/w) physical mixture (grey line) and the 2h co-ground system (black line). No substantial modifications of the PXRD pattern is provoked by co-grinding, this meaning that the process does not yield to drug polymorphs. Adapted from ref [20]. Figure 4. Pure Nimesulide (black line), 0.5h co-ground system (grey thick line) and 1h co-ground system (grey thin line) thermograms performed by differential scanning calorimeter. The reduction of the melting temperature Tmr and enthalpy hcg is evident for the co-ground systems. Figure 5. Pure Nimesulide (black line), 2h co-ground system (grey thick line) and 4h co-ground system (grey thin line) thermograms performed by differential scanning calorimeter. The reduction of melting temperature Tmr and enthalpy hcg is more pronounced with respect to 0.5 and 1 h co-ground systems (see figure 4). Figure 6. Nanocrystals fraction (Xncr) and differential size distribution (f) in the four co-ground systems studied. Rnc is nanocrystals radius. Figure 7A. Calculated trend of nimesulide nanocrystals melting enthalpy (hmr) and temperature Tmr with nanocrystal radius Rnc. Both hmr and Tmr trend depend on nanocrystals fraction Xncr. 22 Figure 7B. Dependence of nimesulide nanocrystals melting enthalpy hmr and temperature Tmr on nanocrystals fraction Xncr setting nanocrystal radius Rnc = 1nm. When Xncr approaches 1, nanocrystals melting occurs inside a wide amount of liquid drug (liquid-vapour curvature radius Rlv becomes infinite). On the contrary, when Xncr approaches 0, only a small amount of liquid drug coats each nanocrystal and Rlv approaches Rnc. Figure 8. Calculated trend of the ratio CsN/CsN∞ (nimesulide nanocrystals solubility/ infinite radius nimesulide crystals). Rnc is nanocrystals radius. CsN/CsN∞ depends on nanocrystals fraction Xncr. O-F indicates the predicted trend of the ratio CsN/CsN∞ according to the Ostwald-Freundlich equation. Figure 9. Experimental data (symbols) referring to Nimesulide concentration (Cr) increase in the release environment relative to the different systems considered (open circles, PVP ClM/Nimesulide physical mixture; open diamonds, 0.5 h co-ground system; filled triangles, 1 h co-ground system; open squares, 2 h co-ground system; filled circles 4 h co-ground system). Solid lines indicate model (eq.(23)) best fitting. Figure 10. Particles size distribution referring to pure PVP Cl-M (open circles), 0.5h co-ground system (open diamonds), 1h co-ground system (filled triangles), 2h co-ground system (open squares) and 4h co-ground system (filled circles). Based on these distributions and assuming a perfect spherical shape of particles, A indicates an approximate estimation of the specific surface area of the different co-ground systems considered. 23 Table 1. Best fitting parameters (kd, dissolution constant; kr, re-crystallisation constant; CsA, amorphous nimesulide solubility) ± standard deviation relative to model (eq.(23)) fitting to release data referring to 0.5h, 1h, 2h and 4h co-ground systems. Csnc indicates nimesulide nano-crystals solubility deduced by eq.(19), A is the co-ground system specific surface area and F is the F statistic value. t kd kr CsA Csnc A*kd F(-) (h) (cm/min) (min-1) (8,233) (g/cm3) (g/cm3) (cm3/min g) 0.5 (1.7 ± 0.2)*10-3 4.0 ± 0.20 1 (8.3 ± 0.8)*10-3 8.5 ± 0.34 18.8 48.8 20.2 153.3 1529.3 4251 ± 377 2 (5.6 ± 0.5)*10-3 4.9 ± 0.16 24.0 90.5 4 (1.0 ± 0.1)*10-3 0.8 ± 0.03 27.3 9.1 24