x2 notation

advertisement

IE312

HW#7 Solution

1 of 5

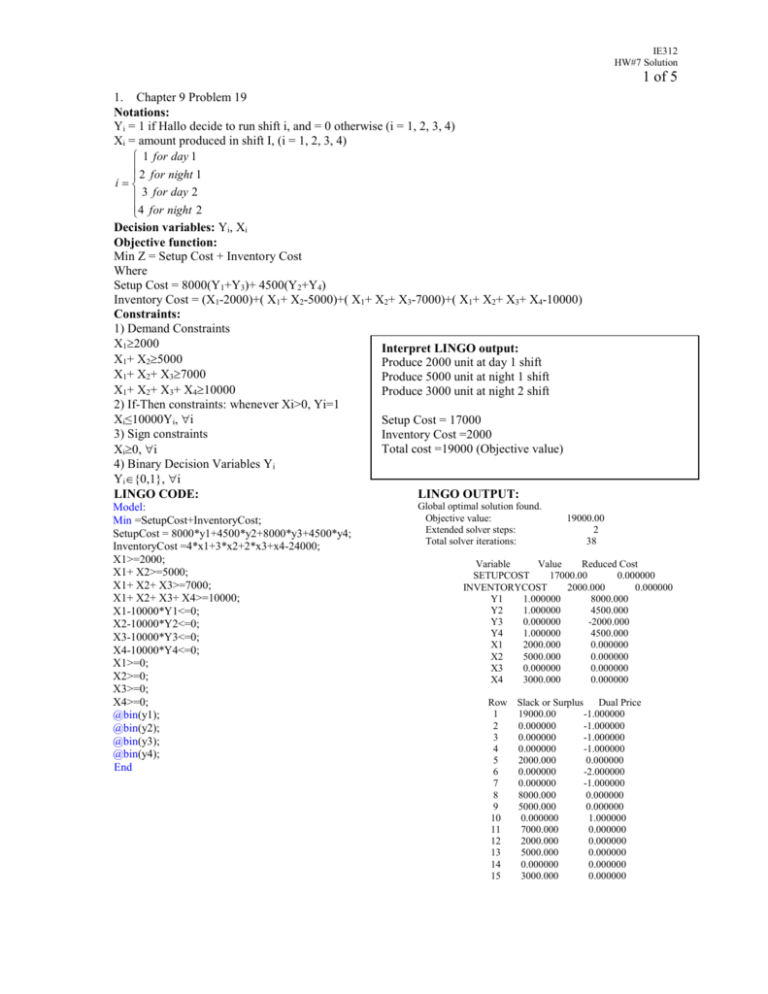

1. Chapter 9 Problem 19

Notations:

Yi = 1 if Hallo decide to run shift i, and = 0 otherwise (i = 1, 2, 3, 4)

Xi = amount produced in shift I, (i = 1, 2, 3, 4)

1 for day 1

2 for night 1

i

3 for day 2

4 for night 2

Decision variables: Yi, Xi

Objective function:

Min Z = Setup Cost + Inventory Cost

Where

Setup Cost = 8000(Y1+Y3)+ 4500(Y2+Y4)

Inventory Cost = (X1-2000)+( X1+ X2-5000)+( X1+ X2+ X3-7000)+( X1+ X2+ X3+ X4-10000)

Constraints:

1) Demand Constraints

X12000

Interpret LINGO output:

X1+ X25000

Produce 2000 unit at day 1 shift

X1+ X2+ X37000

Produce 5000 unit at night 1 shift

X1+ X2+ X3+ X410000

Produce 3000 unit at night 2 shift

2) If-Then constraints: whenever Xi>0, Yi=1

Xi≤10000Yi, i

Setup Cost = 17000

3) Sign constraints

Inventory Cost =2000

Total cost =19000 (Objective value)

Xi0, i

4) Binary Decision Variables Yi

Yi{0,1}, i

LINGO CODE:

LINGO OUTPUT:

Model:

Min =SetupCost+InventoryCost;

SetupCost = 8000*y1+4500*y2+8000*y3+4500*y4;

InventoryCost =4*x1+3*x2+2*x3+x4-24000;

X1>=2000;

X1+ X2>=5000;

X1+ X2+ X3>=7000;

X1+ X2+ X3+ X4>=10000;

X1-10000*Y1<=0;

X2-10000*Y2<=0;

X3-10000*Y3<=0;

X4-10000*Y4<=0;

X1>=0;

X2>=0;

X3>=0;

X4>=0;

@bin(y1);

@bin(y2);

@bin(y3);

@bin(y4);

End

Global optimal solution found.

Objective value:

Extended solver steps:

Total solver iterations:

19000.00

2

38

Variable

Value

Reduced Cost

SETUPCOST

17000.00

0.000000

INVENTORYCOST

2000.000

0.000000

Y1

1.000000

8000.000

Y2

1.000000

4500.000

Y3

0.000000

-2000.000

Y4

1.000000

4500.000

X1

2000.000

0.000000

X2

5000.000

0.000000

X3

0.000000

0.000000

X4

3000.000

0.000000

Row Slack or Surplus

Dual Price

1

19000.00

-1.000000

2

0.000000

-1.000000

3

0.000000

-1.000000

4

0.000000

-1.000000

5

2000.000

0.000000

6

0.000000

-2.000000

7

0.000000

-1.000000

8

8000.000

0.000000

9

5000.000

0.000000

10

0.000000

1.000000

11

7000.000

0.000000

12

2000.000

0.000000

13

5000.000

0.000000

14

0.000000

0.000000

15

3000.000

0.000000

IE312

HW#7 Solution

2 of 5

2. Chapter 9 Problem 20

Same Notations and Decision Variables as #1

Objective function:

Min Z = Setup Cost + Inventory Cost

Where

Setup Cost = 1000(Y1+Y3)+ 3500(Y2+Y4)

Inventory Cost = (X1-2000)+( X1+ X2-5000)+( X1+ X2+ X3-7000)+( X1+ X2+ X3+ X4-10000)

Same Constraints as #1

LINGO CODE:

Model:

Min =SetupCost+InventoryCost;

SetupCost = 1000*y1+3500*y2+1000*y3+3500*y4;

InventoryCost =4*x1+3*x2+2*x3+x4-24000;

X1>=2000;

X1+ X2>=5000;

X1+ X2+ X3>=7000;

X1+ X2+ X3+ X4>=10000;

X1-10000*Y1<=0;

X2-10000*Y2<=0;

X3-10000*Y3<=0;

X4-10000*Y4<=0;

X1>=0;

X2>=0;

X3>=0;

X4>=0;

@bin(y1);

@bin(y2);

@bin(y3);

@bin(y4);

End

LINGO OUTPUT:

Global optimal solution found.

Objective value:

Extended solver steps:

Total solver iterations:

Interpret LINGO output:

Produce 5000 unit at day 1 shift

Produce 5000 unit at day 2 shift

Setup Cost = 2000< 17000 (Setup Cost form #1)

Inventory Cost =6000 > 2000 (Inventory Cost form #1)

Total cost =8000 (Objective value)

Compared result to #1

We see that the setup cost decreases while the inventory cost

increases The decrease in setup costs has actually raised

the average inventory level!

8000.000

3

24

Variable

Value

Reduced Cost

SETUPCOST

2000.000

0.000000

INVENTORYCOST

6000.000

0.000000

Y1

1.000000

1000.000

Y2

0.000000

-6500.000

Y3

1.000000

1000.000

Y4

0.000000

-6500.000

X1

5000.000

0.000000

X2

0.000000

0.000000

X3

5000.000

0.000000

X4

0.000000

0.000000

Row Slack or Surplus

Dual Price

1

8000.000

-1.000000

2

0.000000

-1.000000

3

0.000000

-1.000000

4

3000.000

0.000000

5

0.000000

-2.000000

6

3000.000

0.000000

7

0.000000

-2.000000

8

5000.000

0.000000

9

0.000000

1.000000

10

5000.000

0.000000

11

0.000000

1.000000

12

5000.000

0.000000

13

0.000000

0.000000

14

5000.000

0.000000

15

0.000000

0.000000

IE312

HW#7 Solution

3 of 5

3.

Chapter 9 Problem 22

“A job cannot be processed on machine j unless for all i<j the job has completed its processing on machine i.

once a job begins its processing on machine j, the job cannot be preempted on machine j.”

From above constraint, we know that job 1 has to be produced at M/C 1 first, and then M/C 3, and finally M/C

4, job 2 has to be produced at M/C 1 first, and then M/C 2, and finally M/C 4, and job 3 has to be produced at

M/C 2 first, and finally M/C 3. A summarize of machine order and the processing time for all job are shown

below.

Job

Machine Order

Processing time

1

1-3-4

P11=20. P31=25, P41=30

2

1-2-4

P12=15, P22=20, P42=18

3

2-3

P23=35, P33=28

Notations:

Pij is the processing of job j at machine i, i= 1.2.3.4 and j=1, 2, 3

Yij = Production starting time of job j at machine i

Fj = Flow time of job j

Note that

Flow Time of job j= Production Completion Time of job j at the last M/C the job has been produced–

Production Starting time of job j at the first M/C the job has been produced, and

Production Completion Time of job j at the last M/C the job has been produced = Production Starting Time of

job j at the last M/C the job has been produced + Processing time at the last M/C of the job

Decision variables: Yij

Objective function:

3

Min

F

j 1

j

/3

Where

F1 Y41 30 Y11

F2 Y42 18 Y12

F3 Y33 28 Y23

Constraints:

1) Type 1 Constraints

Y31 Y11 20

Y41 Y31 25

Y22 Y12 15

Y42 Y22 20

Y33 Y23 35

2) Type 2 Constraints

Y11 Y12 15 or

Y22 Y23 35 or

Y31 Y33 28 or

Y41 Y42 18 or

3) Sign Constrains

Fj,Yij 0, i,j

Y12 Y11 20

Y23 Y22 20

Y33 Y31 25

Y42 Y41 30

IE312

HW#7 Solution

4 of 5

4.

Chapter 14 Problem 5

Simulated Annealing (SA) for a single-machine scheduling problem with minimizing tardiness

Notation:

S0 is the best schedule found so far

(k )

(k )

(k )

(k )

(k )

(k )

Sk is the current schedule, Sk = ( j1 , j 2 ,, ji 1 , ji , ji 1 ,, j n )

G(Sk) is the tardiness of a schedule

Sc is the candidate schedule

Aspiration Criterion: G(Sk) G(S0)

Acceptance Criterion: If G(Sc) < G(Sk), accept Sc and let Sk+1 = Sc

If G(Sc) G(Sk), move to Sc with probability P(Sk+1, Sc) = ec/ k

c = G(Sk) - G(Sc)

Step 1:

Set k=1 and select the initial temperature 1,

To choose initial temperature 1 for Simulated Annealing, we will start with the 1 large number that later will

be slowly lowered in cooling steps. The value of 1 depends on maximum possible tardiness (worst schedule).

n

The worst case of the schedule is when all due date (dj) is equal to 0. We have 1=

P

j 1

j

Pj = Processing time of job j

(1)

(1)

(1)

(1)

(1)

(1)

Select an initial schedule S1 and set S0=S1= ( j1 , j 2 ,, ji 1 , ji , ji 1 ,, j n )

Step 2:

Select a candidate schedule Sc from N(Sk).

How to select a candidate depends on neighborhood structure.

Let us considered random pairwise job interchange as a type of schedule generation schemes. The schedule is

generated by randomly selecting any pair of distinct jobs within the schedule and exchanging their position.

(k )

(k )

(k )

(k )

(k )

(k )

Since Sk = ( j1 , j 2 ,, ji 1 , ji , ji 1 ,, j n ) , when exchanging position i with position i+1

(k )

(k )

(k )

(k )

(k )

(k )

we will have Sc = ( j1 , j 2 ,, ji 1 , ji 1 , ji ,, j n )

If G(S0)< G(Sc) < G(Sk), set Sk+1 = Sc and go to step 3

If G(Sc)< G(S0), set S0 =Sk+1 = Sc and go to step 3

If G(Sc) < G(S0), generate Uk~Uniform(0,1);

If Uk≤P(Sk, Sc), set Sk+1 = Sc; otherwise set Sk+1 = Sk; go to step 3

Step 3:

Select k+1≤k,

Let k = k+1, if k= N STOP; otherwise go to Step 2.

Note that as k decreases, the lower the probability to accept worse schedules.

IE312

HW#7 Solution

5 of 5

5. Chapter 14 Problem 8

For solving Knapsack problem, we learn that each decision variable must equal 0 or 1

Let Vi is the decision whether to put item i in the knapsack, where Vi = 1 if item i is put in the knapsack, = 0

otherwise (Vi {0,1}).

Notation:

X0 is the best schedule found so far

(k )

Xk = is the current knapsack decision, X k = (V1

,V2( k ) ,,Vn( k ) )

G(Xk) is the benefit obtained from the knapsack

Xc is the candidate schedule

Tabu Search (TS) combined with single complement moves:

Step 1:

Set k=1, select an initial solution X1 and set X0 =X1

( 0)

Start with a initial solution X0= (V1

,V2(0) ,,V j(0) ,,Vn(0) ) ,

Specify the length of tabu list as a fix length (L),

the length of tabu list (L) usually can be between 5 and 9.

Step 2:

Select a candidate solution Xc from N(Xk)

Using single complement moves to create the neighborhood solutions N(X k), selecting a position within the

schedule and change its value.

N(Xk) =

(V1(0) ,V2(0) ,,1 V j(0) ,,Vn(0) ) ,

For example:

X0=(1, 0, 0, 1, …, 1, …,0), with a single complement move we will have the set of

neighborhood solutions N(X0) as{(0, 0, 0, 1, …, 1, …,0), (1, 1, 0, 1, …, 1, …,0), (1, 0, 1, 1, …, 1, …,0), …., (1,

0, 0, 0, …, 1, …,0), (1, 0, 0, 1, …, 0, …,0), …, (1, 0, 0, 1, …, 1, …,1)}.

Candidate solution Xc= is the solution which is not tabu and has the best G(X k).

Let us assume Xc= (1, 0, 0, 1, …, 0, …,0) for example.

Enter Xc Xk on tabu list, which is the change of Vj to 1-Vj in this example.

Push all the other entries down (and delete the last one).

If G(Xc)<G(X0) set X0=Xc and go to step 3.

Step 3:

Let k = k+1, if k= N STOP; otherwise go to Step 2.