Physics 202 - Personal.psu.edu

advertisement

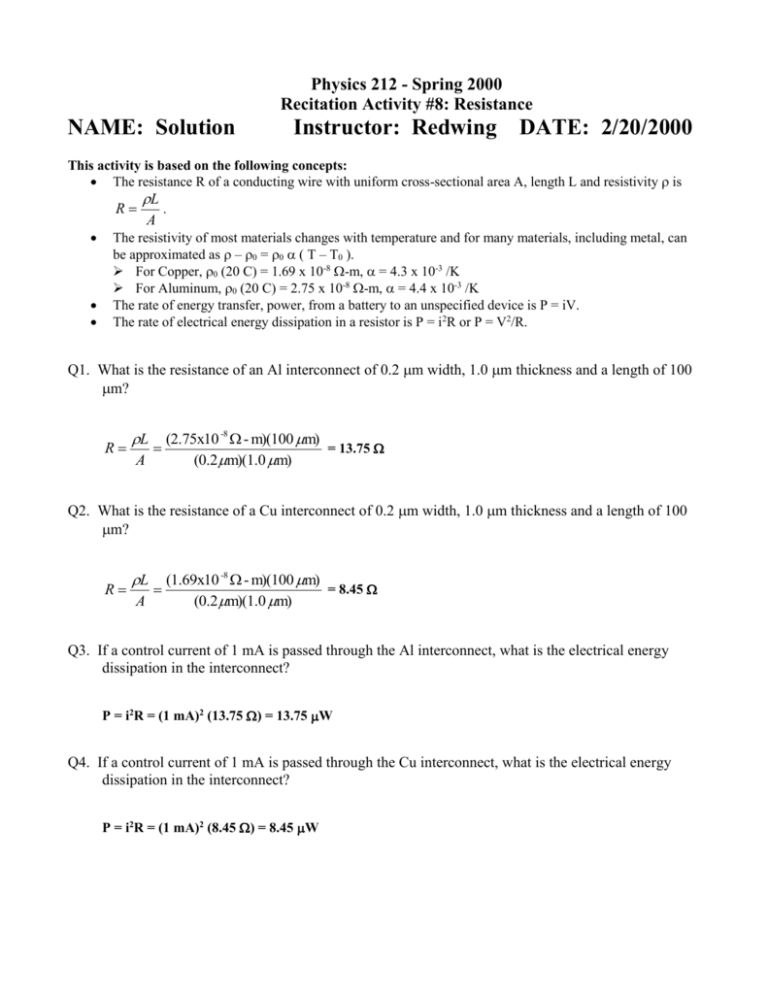

Physics 212 - Spring 2000 Recitation Activity #8: Resistance NAME: Solution Instructor: Redwing DATE: 2/20/2000 This activity is based on the following concepts: The resistance R of a conducting wire with uniform cross-sectional area A, length L and resistivity is R L A . The resistivity of most materials changes with temperature and for many materials, including metal, can be approximated as – 0 = 0 ( T – T0 ). For Copper, 0 (20 C) = 1.69 x 10-8 -m, = 4.3 x 10-3 /K For Aluminum, 0 (20 C) = 2.75 x 10-8 -m, = 4.4 x 10-3 /K The rate of energy transfer, power, from a battery to an unspecified device is P = iV. The rate of electrical energy dissipation in a resistor is P = i2R or P = V2/R. Q1. What is the resistance of an Al interconnect of 0.2 m width, 1.0 m thickness and a length of 100 m? R L A (2.75x10 -8 - m)(100 m) = 13.75 (0.2m)(1.0 m) Q2. What is the resistance of a Cu interconnect of 0.2 m width, 1.0 m thickness and a length of 100 m? R L A (1.69x10 -8 - m)(100 m) = 8.45 (0.2 m)(1.0 m) Q3. If a control current of 1 mA is passed through the Al interconnect, what is the electrical energy dissipation in the interconnect? P = i2R = (1 mA)2 (13.75 ) = 13.75 W Q4. If a control current of 1 mA is passed through the Cu interconnect, what is the electrical energy dissipation in the interconnect? P = i2R = (1 mA)2 (8.45 ) = 8.45 W Q5. Using the information from the reading, what would you estimate the total electrical energy dissipation of the interconnects to be for a single microprocessor chip if the average length of an Al interconnect is 100 m? (Note: one mile ~ 1600 m) PTotal = 400m Al P1 00m = ( 4 x 106 )( 13.75 W ) = 55 W 100 m Q6. Using the information from the reading, what would you estimate the total electrical energy dissipation of the interconnects to be for a single microprocessor chip if the average length of an Cu interconnect is 100 m? PTotal = 400m Cu P100m = ( 4 x 106 )( 8.45 W ) = 34 W 100m Q7. The rate of the total electrical energy dissipation for a single microprocessor chip is quite high and even with cooling fans, the energy dissipation can lead to a temperature of 40 C at the chip. What is the your new estimate for Q6 if the temperature of the chip is 40 C? – 0 = 0 ( T – T0 ) P40Total P20Total P20Total (40C 20C ) (34W )( 4.3 x10 3 / C )( 20C ) = 2.9 W P40Total = (34 + 3) W = 37 W Scoring Guidelines: 100 90 75 60 40 0 All correct miss one some correct none to few correct, but shows effort Turned in paper, but no real effort No paper IBM developed Copper interconnect technology increases computer performance1 Put simply, copper is a more efficient conductor than aluminum, making it useful in processors because it allows for smaller, thinner interconnects. Interconnects are tiny pieces of wire that connect transistors inside a processor. Smaller interconnects make for smaller, higher-performance chips because chip makers can pack more transistors into a smaller space. Copper's properties also make it more power-efficient than aluminum. Copper increases microprocessor performance substantially compared with chips that use traditional aluminum wire. A single POWER3-II chip -- about the size of a thumbnail -- contains a quarter mile of copper wiring. Copper Is The Answer After nearly 15 years of research, IBM scientists announced in September 1997 a new advance in semiconductor process that entails replacing aluminum with copper. Copper has less "resistance" than aluminum, and therefore transmits electrical signals faster. However, it doesn't mix as well with silicon, the base material of semiconductor chips. The IBM researchers found a way to put a microscopic barrier between the copper and silicon in a way that actually reduced the number of steps needed to complete a chip. With this development, IBM is able to produce extremely intricate circuit designs with copper at widths of 0.20 microns -- down from the current industry standard of 0.25 microns - a reduction far more difficult for aluminum. (A micron is over 100 times thinner than a human hair.) The copper-stimulated reduction in dimensions will permit designers to pack 150 million to 200 million transistors on a single chip. Copper will become more widespread in the semiconductor industry for several compelling reasons. Copper wires conduct electricity with about 40 percent less resistance than aluminum. That translates into a speedup of as much as 15 percent in microprocessors that contain copper wires. Copper wires are also far less vulnerable than those made of aluminum to electromigration, the movement of individual atoms through a wire, caused by high electric currents, which creates voids and ultimately breaks the wires. As a remarkable added benefit, IBM's method of depositing copper wires on chips means a potential cost saving of up to 30 percent for the wiring or 10 to 15 percent for the full wafer. Despite its many virtues, copper didn't become a success overnight. For, while the semiconductor industry recognized its potential more than 30 years ago, the perceived danger of using copper acted as a brake on its development as an interconnect. Not only does copper rapidly diffuse into silicon, the substrate in which the transistors are formed, but it changes the electrical properties of silicon in such a way as to prevent the transistors from functioning. "Copper was considered to be a killer to semiconductor devices," says IBM Fellow Lubomyr Romankiw. "The conventional wisdom was to stay as far away from copper as you could." IBM's copper program managed to solve all the problems that faced the use of the element. One by one, scientists and engineers overcame the hurdles standing in the way of a viable technology. These ranged from a means of depositing copper on silicon to the development of an ultrathin barrier to isolate copper wires from silicon. Since introducing copper technology into volume production, IBM has incorporated copper into stand-alone processors in S/390 and RS/6000 systems, Apple Computer's iBook and PowerBook, as well as a variety of custom chips for leading networking products. IBM has said a copper-based PowerPC chip will also power a forthcoming game console from Nintendo. 1 Major portions excerpted from Internet article, “Copper supercharges IBM supercomputers, ” by John G. Spooner, ZDNet News, Wednesday February 09, 2000 and IBM web site.