Strain Gradient Notation for Finite Elements Polynomials

advertisement

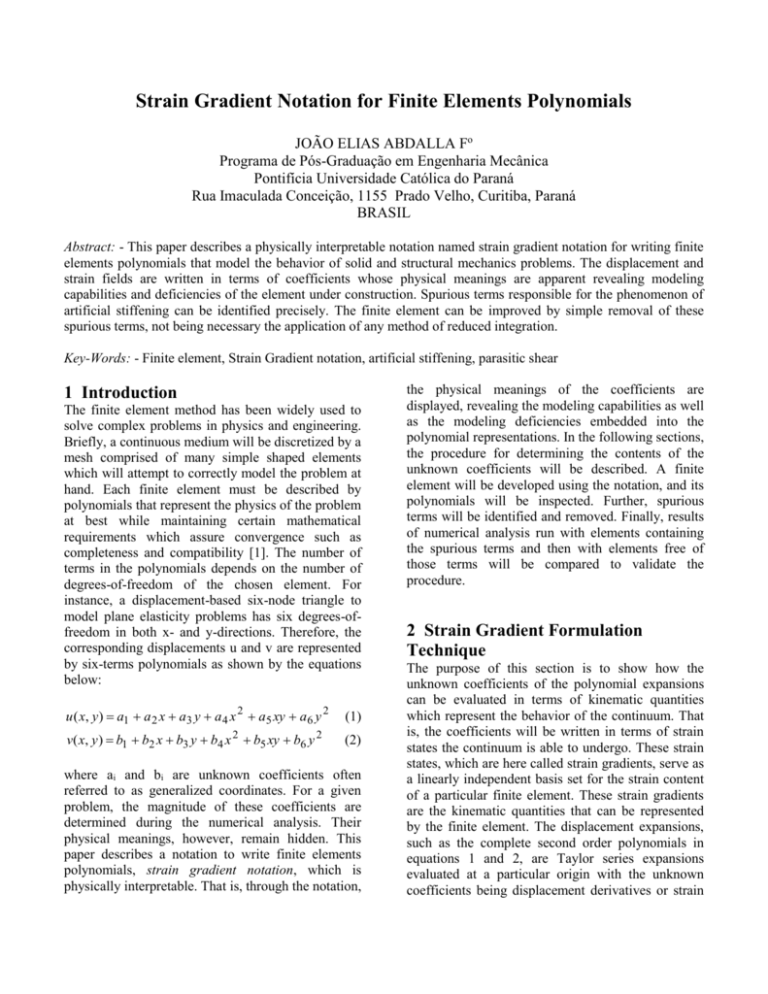

Strain Gradient Notation for Finite Elements Polynomials JOÃO ELIAS ABDALLA Fo Programa de Pós-Graduação em Engenharia Mecânica Pontifícia Universidade Católica do Paraná Rua Imaculada Conceição, 1155 Prado Velho, Curitiba, Paraná BRASIL Abstract: - This paper describes a physically interpretable notation named strain gradient notation for writing finite elements polynomials that model the behavior of solid and structural mechanics problems. The displacement and strain fields are written in terms of coefficients whose physical meanings are apparent revealing modeling capabilities and deficiencies of the element under construction. Spurious terms responsible for the phenomenon of artificial stiffening can be identified precisely. The finite element can be improved by simple removal of these spurious terms, not being necessary the application of any method of reduced integration. Key-Words: - Finite element, Strain Gradient notation, artificial stiffening, parasitic shear 1 Introduction The finite element method has been widely used to solve complex problems in physics and engineering. Briefly, a continuous medium will be discretized by a mesh comprised of many simple shaped elements which will attempt to correctly model the problem at hand. Each finite element must be described by polynomials that represent the physics of the problem at best while maintaining certain mathematical requirements which assure convergence such as completeness and compatibility [1]. The number of terms in the polynomials depends on the number of degrees-of-freedom of the chosen element. For instance, a displacement-based six-node triangle to model plane elasticity problems has six degrees-offreedom in both x- and y-directions. Therefore, the corresponding displacements u and v are represented by six-terms polynomials as shown by the equations below: u ( x, y ) a1 a 2 x a3 y a 4 x 2 a5 xy a 6 y 2 (1) v( x, y ) b1 b2 x b3 y b4 x 2 b5 xy b6 y 2 (2) where ai and bi are unknown coefficients often referred to as generalized coordinates. For a given problem, the magnitude of these coefficients are determined during the numerical analysis. Their physical meanings, however, remain hidden. This paper describes a notation to write finite elements polynomials, strain gradient notation, which is physically interpretable. That is, through the notation, the physical meanings of the coefficients are displayed, revealing the modeling capabilities as well as the modeling deficiencies embedded into the polynomial representations. In the following sections, the procedure for determining the contents of the unknown coefficients will be described. A finite element will be developed using the notation, and its polynomials will be inspected. Further, spurious terms will be identified and removed. Finally, results of numerical analysis run with elements containing the spurious terms and then with elements free of those terms will be compared to validate the procedure. 2 Strain Gradient Formulation Technique The purpose of this section is to show how the unknown coefficients of the polynomial expansions can be evaluated in terms of kinematic quantities which represent the behavior of the continuum. That is, the coefficients will be written in terms of strain states the continuum is able to undergo. These strain states, which are here called strain gradients, serve as a linearly independent basis set for the strain content of a particular finite element. These strain gradients are the kinematic quantities that can be represented by the finite element. The displacement expansions, such as the complete second order polynomials in equations 1 and 2, are Taylor series expansions evaluated at a particular origin with the unknown coefficients being displacement derivatives or strain gradient quantities. The determination of the coefficients requires the evaluation of displacements and their derivatives at the element´s local origin. Then, u0,0 u0 a1 v0,0 v0 b1 (3) (4) where [u]0 and [v]0 are the rigid body displacement modes evaluated at the origin. The normal strains are given by: u a 2 2a 4 x a5 y x v y x, y b3 b5 x 2b6 y y x x, y (5) (6) 0 b3 y 0,0 y 1 v u 2 x y 1 b2 a3 2b4 a5 x b5 2a 6 y 2 u v xy x, y x y a3 b2 a5 2b4 x 2a 6 b5 y (7) (8) (9) (10) which are evaluated at the origin to yield r 0,0 r 0 1 b2 a3 2 xy 0,0 xy a3 b2 0 (11) (12) Solution of equations 11 and 12 yields 0 a3 xy 2 r 0 b2 xy 2 r (15) 0 a 6 xy , y y , x 2 0 b4 xy , x x, y 2 0 b5 y , x 0 b6 y , y 2 0 (16) (17) (18) (19) (20) Therefore, all the coefficients have been evaluated in terms of strain gradients, rendering displacement polynomial expansions whose physical meanings are transparent to the analyst. Substitution of the results above into equations 1 and 2 yields u ( x, y ) u 0 x 0 x xy 2 r y x, x / 2 0 x 2 0 The small-displacement rotation and shear strain are given by: r x, y a 4 x, x / 2 0 a5 x , y which are evaluated at the origin to yield x 0,0 x 0 a 2 Evaluation of the higher-order derivatives of the strains at the origin yields after manipulation (13) (14) 0 xy xy , y y, x 20 y 2 x, y (21) 0 0 y (22) xy, x x, y 20 x 2 y, x 0 xy y, y 20 y 2 v( x, y ) v 0 xy 2 r x y These equations show that the displacements depend mostly on rigid body translations [u]0, [v]0 and rigid body rotation [r]0, and on constant normal and shear strains [x]0, [y]0 and [xy]0. Also, they show that the displacements depend on first gradients of these normal and shear strains, i.e., [x,x]0, [x,y]0, [y,x]0 , [y,y]0 , [xy,x]0 and [xy,y]0. This procedure has been carried out for the complete, three-dimensional, fourth-order displacement polynomials to determine the contents of the coefficients in terms of strain gradients [2]. The results have been conveniently organized in table form allowing for the construction of virtually any finite element displacement approximation function. In the process of formulating a given finite element using strain gradient notation, nodal displacements are written in terms of strain gradient quantities through the following expression: d sg (23) where d is the vector of nodal displacements, sg is the vector of strain gradient quantities, and is the matrix relating nodal displacements to strain gradients. The columns in are all linearly independent once the strain gradients form a linearly independent basis set for the finite element. These column vectors of the transformation matrix contain the nodal displacements and rotations required to produce a given strain state. The continuum elastic strains are related to the individual strain gradients through Substituting sg from equation 23 into equation 26 gives Tsg sg the element´s stiffness matrix is then calculated by 1 T C dV V 2 (25) where C is the constitutive matrix, which relates stresses to strains. Substitution of equation 24 into 25 yields U scalar 1 T T sg Tsg C Tsg sg dV V 2 (26) Considering that the strain gradients do not vary with the volume of the element, the strain energy matrix is defined as U 1 TsgT C Tsg dV V 2 1 T T d U 1d 2 (28) Recalling that U scalar 1 T d Kd 2 (29) (24) where is the vector of continuum elastic strains, and Tsg is the transformation matrix between these strains and the strain gradients. The contents of this matrix results from the substitution of the displacement expansions into the strain definitions. Further, the general strain energy equation for a deformable body is U scalar U scalar (27) The strain energy matrix is a symmetric matrix of strain energy quantities. Its diagonal terms are interpreted as the amount of strain energy contained in the element when it is subjected to a deformation associated to one of the strain gradients. This deformation is the displacement vector in matrix corresponding that strain gradient. The off-diagonal terms are the strain energy associated to the coupling of two deformation modes which in turn are associated to two strain gradients. K T U 1 (30) 3 A-Priori Evaluation of Modeling Characteristics The transparency of the strain gradient notation allows for the determination of the modeling characteristics of a finite element prior to numerical analysis. Evaluation of the displacement polynomials of the six-node triangle (equations 21 and 22) shows for instance that rigid body and constant strain modes contribute to the field. Therefore, the element possesses the theoretical requirements for convergence [1]. According to equations 5, 6 and 10, the strains are given by 0 y (31) 0 y,x 0 x y, y 0 y (32) x ( x, y ) x 0 x, x 0 x x, y y ( x, y ) y 0 xy,x 0 x xy, y 0 y xy ( x, y ) xy (33) which show that every term in the polynomials is a legitimate one because all of them belong to the Taylor series expansions associated to the corresponding strain quantity on the left-hand side. This explains why the six-node triangle is such an efficient element presenting a high rate of convergence. The reason this element does not contain spurious terms in its polynomial expansions is that it is derived from complete polynomials. In fact, any element whose polynomials are complete do not contain erroneous terms, thus not developing parasitic shear. Let´s now consider the four-node quadrilateral element. Its displacement polynomials are given by u ( x, y ) u 0 x 0 x xy 2 r y 0 x, y xy 0 v( x, y ) v 0 xy 2 r x y y 0 0 y , x xy 0 (34) (35) and the corresponding strain polynomials are given by 0 y y ( x, y ) y y , x x 0 0 x ( x, y ) x 0 x, y 0 x, y 0 x y, x 0 y xy ( x, y ) xy (36) (37) (38) Inspection of equations 36 and 37 shows that the normal strains are pure Taylor series expansions. However, the shear strain expression contains derivatives of normal strains, i.e. flexural terms, which are not terms of the Taylor series expansion of xy. This gives coupling between normal and shear strains when the element is subjected to bending. That is, during bending these erroneous terms are activated increasing the value of xy unduly which in turn increases the stiffness of the element. This phenomenon is called artificial stiffening. Because these spurious terms contaminate the shear strain expression they are referred to as parasitic shear terms, and their effect of artificial stiffening is named parasitic shear. When regular notation is used such as in isoparametric finite elements [1] the modeling characteristics of the polynomial expansions are not revealed a-priori such as it was done above. In that case, artificial stiffening has to be dealt with during numerical analysis through some form of the reduced integration technique [1]. On the other hand, when strain gradient notation is employed as was done above, the modeling characteristics of the element become transparent to the analyst, and erroneous terms which are inherent to the formulation can be precisely identified. Because the strain gradients form a set of independent quantities, the erroneous terms can be simply removed from the shear strain expansion without reducing the modeling capabilities of the element. Hence, the corrected shear strain expression of the four-node quadrilateral element is xy ( x, y ) xy 0 (39) which results from eliminating the two spurious flexural terms from equation 38. At this point, it is to be noted that those terms were not removed from the basis set of the element as they still appear in the normal strains expressions and in the displacements expressions. This ensures that the element will perform at its best. As far as eliminating errors is concerned, the same result is obtained when reduced integration is used when integrating the stiffness matrix terms of a fournode isoparametric quadrilateral. More specifically, integration with one-point reduced order Gauss quadrature rule eliminates the effects of the parasitic shear terms. Therefore, it is an alternative and effective approach. However, reduced integration is not as effective when employed in analyses with the eight-node isoparametric quadrilateral element. Either a portion of the added strain energy due to parasitic shear is left in the strain energy expression or the strain energy due to required terms is removed. In the former case, the element is still overly stiff, whereas in the latter the strain energy is reduced and a new error known as spurious zero energy modes is introduced. Further details about this matter can be found in the work of Dow and Abdalla [3]. This case of the eight-node quadrilateral indicates the importance of a physically interpretable notation such as strain gradient notation. The correcting procedure allowed by it is always effective ensuring good quality of results in the sense that all erroneous terms can be fully removed without introducing any other deleterious effects. The strain gradient notation was first used in the analysis of continuum lattice structures [4, 5]. Then, it has been used in finite elements analysis to model plane elasticity problems [2, 6], plate problems [2, 7], and laminated composite plate [8] and laminated composite beam problems [9]. 4 Numerical Validation The effectiveness of the procedure for removing parasitic shear terms from the shear strain expression of the four-node quadrilateral to render a better finite element is demonstrated in this section. A cantilever beam subjected to an end shear load of unit value, as shown in figure 1, is analyzed using four-node quadrilateral meshes both with and without the parasitic shear terms identified earlier. This problem is heavily influenced by bending, which creates an environment where the artificial stiffening produced by parasitic shear terms is very significant. Table 1 Results of Cantilever Beam Analysis Modeled with 4-Node Plane Quadrilateral Elements. MAXIMUM DEFLECTION MESH Element Error Element Error with (%) without (%) parasitic parasitic shear shear 1x2 0.376 90.67 3.439 14.69 1x10 2.716 32.63 3.657 9.28 2x20 3.581 11.17 3.915 2.88 4x40 3.901 3.23 3.994 0.92 Correct Deflection = 4.0312 elasticity modulus of the material, G is the shear modulus of the material, and K is the shear correction factor. In this example, the values used are P = 1.0, L = 10.0, E = 1,000.00, G = 384.615, A = 1.0, I = 1/12, and K = 5/6. The values displayed in table 1 clearly show the difference between results obtained with elements containing parasitic shear terms and those obtained with elements corrected for this deficiency. The coarser the mesh the more evident is that difference. It is also shown that refinement tends to attenuate the artificial stiffening caused by parasitic shear and that eventually convergence will be attained. However, convergence occurs much sooner when corrected elements are employed. This is easily seen by studying the percent error columns. The error in the results using the coarser mesh is 90.67% when parasitic shear is present, and only 14.69% after removal of parasitic shear. These error values are very effective to demonstrate the strength of parasitic shear in finite element analyses and also to validate the error elimination procedure allowed by strain gradient notation. Further, the third mesh, which contains only 40 elements, produces results with 11.17% error when parasitic shear is present, and results with only 2.88% error after removal of parasitic shear. Finally, the finer mesh, which contains 160 elements, presents results with only 0.92% error after removal of parasitic shear while the error is 3.23% with parasitic shear. It can be concluded from these analyses that if the element is corrected for parasitic shear, coarser meshes already produce acceptable results. On the other hand, if the effects of parasitic shear are to be attenuated by refinement, much finer meshes may be necessary for accurate results. Furthermore, the error elimination procedure of simply removing the spurious terms from the shear strain polynomial works well as the numerical analysis results converge to the correct analytical solution. The correct deflection is given by the following analytical expression 5 Summary and Conclusions 1,0 1,0 10,0 Fig.1 Cantilever beam modeled by strain gradient quadrilateral plane elements. Four meshes are constructed, namely; 1x2, 1x10, 2x20, and 4x40. The first number is the number of subdivisions of the mesh along the vertical direction while the second number is the number of subdivisions along the horizontal direction. The result used for comparison is the maximum deflection of the beam. The results of the analyses as well as the percent error contained in those results are shown in Table 1 below. PL3 PL 3EI KGA (40) where P is the applied load, L is the length of the beam, A is its cross-section area, I is the moment of inertia of the cross-section, E is the longitudinal This paper presents a physically interpretable notation, strain gradient notation, for expressing the polynomial expansions which represents the displacement and strain fields of solid mechanics problems to be modeled by finite elements. It is shown that the unknown coefficients of these polynomial expansions are expressed in terms of the kinematic quantities of the continnum, that is, the quantities which contribute to the deformation of the solid body. These quantities are rigid body displacements, constant strains, and gradients of strains, which, in the present context, have been called strain gradients. It has been demonstrated here that strain gradient notation allows the analyst to determine a-priori which are the modeling capabilities of a given finite element. By the same token, he or she can identify spurious terms which are responsible for artificial stiffening. In the present work, the procedure for identifying and eliminating parasitic shear terms effectively using a widely employed finite element has been shown. That procedure is valid for any finite element containing spurious terms. The conclusion is that strain gradient notation is effective for formulating finite elements. This is so mainly for allowing the identification of inherent erroneous terms which are the sources of artificial stiffening. This is important because only those terms are eliminated in the process of correcting the element´s polynomial expansions. That is, genuine terms are not removed blindly such as is the case of the eight-node quadrilateral when reduced integration is employed. Strain gradient notation through this paper has been shown once again. Even though it has been used for over fifteen years in finite element analysis, the notation is not known by many members of the computational mechanics community, and its advantages not necessarily appreciated. It is hoped that the efforts being made in developing and applying strain gradient notation further will render it a widely well recognized procedure. References: [1] O. C. Zienkiewicz and R. L. Taylor, The Finite Element Method, Fourth Edition, Vol. 1, McGraw-Hill Book Company, London, 1989. [2] D.E. Byrd, Identification and Elimination of Errors in Finite Element Analysis, Ph.D. Dissertation, University of Colorado, Boulder, CO, 1988. [3] J.O. Dow and J.E. Abdalla Fo, Qualitative Errors in Laminated Composite Plate Models, International Journal for Numerical Methods in Engineering, Vol. 37, 1215-1230, 1994. [4] J.O. Dow, T.H. Ho, and H.D. Cabiness, A Generalized Finite Element Evaluation Procedure, ASCE Journal of Structural Engineering, Vol.111, No.2, pp 435-452, 1985. [5] J.O. Dow and S.A. Huyer, Continuum Models of Space Station Structures, ASCE Journal of Aerospace Engineering, Vol.2, No.4, pp 212-230, 1989. [6] J.O. Dow, H.D. Cabiness, and T.H. Ho, A Linear Strain Element with Curved Edges, ASCE Journal of Structural Engineering, Vol.112, No.4, pp 692-708, 1986. [7] J.O. Dow and D.E. Byrd, Error Estimation Procedure for Plate Bending Elements, AIAA Journal, Vol.28, No.4, pp 685-693, 1990. [8] J.E. Abdalla Fo, Qualitative and Discretization Error Analysis of Laminated Composite Plate Models, Ph.D. Dissertation, University of Colorado, Boulder, CO, 1992.