Chapter 13

advertisement

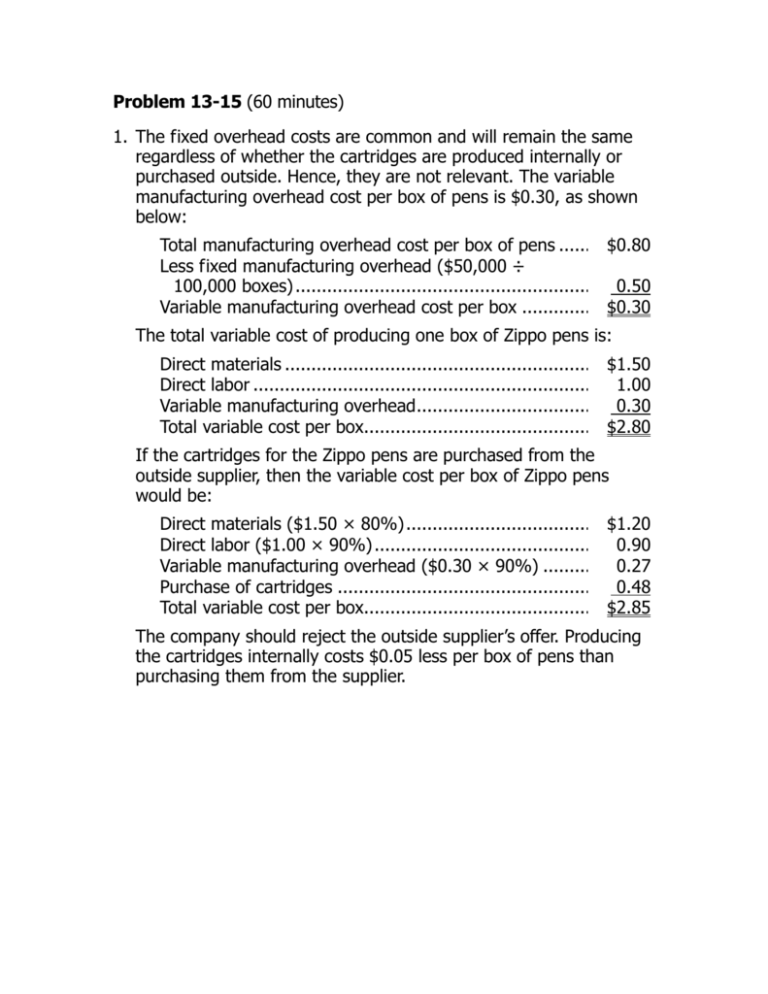

Problem 13-15 (60 minutes) 1. The fixed overhead costs are common and will remain the same regardless of whether the cartridges are produced internally or purchased outside. Hence, they are not relevant. The variable manufacturing overhead cost per box of pens is $0.30, as shown below: Total manufacturing overhead cost per box of pens ........................ $0.80 Less fixed manufacturing overhead ($50,000 ÷ 100,000 boxes) .......................................................................... 0.50 Variable manufacturing overhead cost per box ............................... $0.30 The total variable cost of producing one box of Zippo pens is: Direct materials ..............................................................$1.50 Direct labor .................................................................... 1.00 Variable manufacturing overhead ..................................... 0.30 Total variable cost per box...............................................$2.80 If the cartridges for the Zippo pens are purchased from the outside supplier, then the variable cost per box of Zippo pens would be: Direct materials ($1.50 × 80%) .......................................$1.20 Direct labor ($1.00 × 90%) ............................................. 0.90 Variable manufacturing overhead ($0.30 × 90%) ............. 0.27 Purchase of cartridges .................................................... 0.48 Total variable cost per box...............................................$2.85 The company should reject the outside supplier’s offer. Producing the cartridges internally costs $0.05 less per box of pens than purchasing them from the supplier. Problem 13-15 (continued) Another approach to the solution is: Cost avoided by purchasing the cartridges: Direct materials ($1.50 × 20%) ....................................$0.30 Direct labor ($1.00 × 10%) .......................................... 0.10 Variable manufacturing overhead ($0.30 × 10%) ........... 0.03 Total costs avoided .......................................................$0.43 Cost of purchasing the cartridges.....................................$0.48 Cost savings per box by making cartridges internally ........$0.05 Note that the avoidable cost of $0.43 above represents the cost of making one box of cartridges internally. 2. The company would not want to pay any more than $0.43 per box, since it can make the cartridges for this amount internally. 3. The company has three alternatives for obtaining the necessary cartridges. It can: #1 #2 #3 Produce all cartridges internally. Purchase all cartridges externally. Produce 100,000 boxes internally and purchase 50,000 boxes externally. Problem 13-15 (continued) The costs under the three alternatives are: Alternative #1—Produce all cartridges internally: Variable costs (150,000 boxes × $0.43 per box) ............. Fixed costs of adding capacity ....................................... Total cost ..................................................................... $64,500 30,000 $94,500 Alternative #2—Purchase all cartridges externally: Variable costs (150,000 boxes × $0.48 per box)............... $72,000 Alternative #3—Produce 100,000 boxes internally, and purchase 50,000 boxes externally: Variable costs: 100,000 boxes × $0.43 per box ................................ 50,000 boxes × $0.48 per box .................................. Total cost..................................................................... $43,000 24,000 $67,000 Or, in terms of total cost per box of pens, the answer would be: Alternative #1—Produce all cartridges internally: Variable costs (150,000 boxes × $2.80 per box) ............. $420,000 Fixed costs of adding capacity ....................................... 30,000 Total cost ..................................................................... $450,000 Alternative #2—Purchase all cartridges externally: Variable costs (150,000 boxes × $2.85 per box) ............. $427,500 Alternative #3—Produce 100,000 boxes internally, and purchase 50,000 boxes externally: Variable costs: 100,000 boxes × $2.80 per box ............................... $280,000 50,000 boxes × $2.85 per box................................. 142,500 Total cost................................................................... $422,500 Thus, the company should accept the outside supplier’s offer, but only for 50,000 boxes of cartridges. Problem 13-15 (continued) 4. In addition to cost considerations, Bronson should take into account the following factors: a) The ability of the supplier to meet required delivery schedules. b) The quality of the cartridges purchased from the supplier. c) Alternative uses of the capacity that is used to make the cartridges. d) The ability of the supplier to supply cartridges if volume increases in future years. e) The problem of alternative sources of supply if the supplier proves undependable. Problem 13-16 (30 minutes) 1. Incremental revenue: Fixed fee (10,000 pairs × 4 mk per pair) ....................... 40,000 mk Reimbursement for costs of production: (Variable production cost of 16 mk plus fixed overhead cost of 5 mk equals 21 mk per pair; 10,000 pairs × 21 mk per pair) .................................. 210,000 Total incremental revenue ............................................ 250,000 Incremental costs: Variable production costs (10,000 pairs × 16 mk per pair) ............................................................. 160,000 Increase in net operating income .................................... 90,000 mk 2. Sales revenue through regular channels (10,000 pairs × 32 mk per pair) ................................... 320,000 mk Sales revenue from the army (above) .............................. 250,000 Decrease in revenue received ......................................... 70,000 Less variable selling expenses avoided if the army’s offer is accepted (10,000 pairs × 2 mk per pair) ..................................................................... 20,000 Net decrease in net operating income with the army’s offer................................................................. 50,000 mk Problem 13-20 (45 minutes) 1. Only the avoidable costs are relevant in a decision to drop the Kensington product line. These costs are: Direct materials .............................................................. £ 32,000 Direct labor ....................................................................200,000 Fringe benefits (30% of labor) ........................................ 60,000 Variable manufacturing overhead .................................... 30,000 Royalties (5% of sales) ................................................... 24,000 Product-line managers’ salaries ....................................... 8,000 Sales commissions (10% of sales) ................................... 48,000 Fringe benefits (30% of salaries and commissions) .......... 16,800 Shipping ........................................................................ 10,000 Advertising .................................................................... 15,000 Total avoidable cost ........................................................ £443,800 The following costs are not relevant in this decision: Cost Reason not relevant Building rent and maintenance All products use the same facilities; no space would be freed up if a product were dropped. Depreciation All products use the same equipment so no equipment can be sold. Furthermore, the equipment does not wear out through use. General administrative expenses Dropping the Kensington product line would have no effect on total general administrative expenses. Problem 13-20 (continued) Having determined the costs that can be avoided if the Kensington product line is dropped, we can now make the following computation: Sales revenue lost if the Kensington line is dropped..........£480,000 Less costs that can be avoided (see above) ..................... 443,800 Decrease in overall company net operating income if the Kensington line is dropped......................................£ 36,200 Thus, the Kensington line should not be dropped unless the company can find more profitable uses for the resources consumed by the Kensington line. 2. To determine the minimum acceptable sales level, we must first classify the avoidable costs into variable and fixed costs as follows: Variable Fixed Direct materials .............................................................. £ 32,000 Direct labor .................................................................... 200,000 Fringe benefits (30% of labor) ........................................ 60,000 Variable manufacturing overhead .................................... 30,000 Royalties (5% of sales) ................................................... 24,000 Product-line managers’ salaries ....................................... £ 8,000 Sales commissions (10% of sales) ................................... 48,000 Fringe benefits (30% of salaries and commissions) ............................... 14,400 2,400 Shipping ........................................................................ 10,000 Advertising .................................................................... 15,000 Total cost ....................................................................... £418,400 £25,400 The Kensington product line should be retained as long as its contribution margin covers its avoidable fixed costs. Break-even analysis can be used to find the sales volume where the contribution margin just equals the avoidable fixed costs. Problem 13-20 (continued) The contribution margin ratio is computed as follows: CM ratio = = Contribution margin Sales £480,000 - £418,400 = 12.83% (rounded) £480,000 And the break-even sales volume can be found using the breakeven formula: Break- even point = = Fixed expenses CM ratio £25,400 = £198,000 (rounded) 0.1283 Therefore, as long as the sales revenue from the Kensington product line exceeds £198,000, it is covering its own avoidable fixed costs and is contributing toward covering the common fixed costs and toward the profits of the entire company.