Multiple Storage Conditions

advertisement

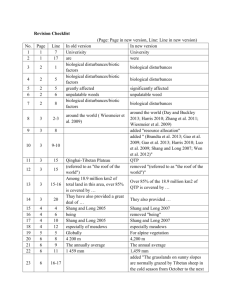

Multiple Storage Conditions: Accumulating Uncertainty Brad Evans Pfizer MBSW, May 23, 2012 Question • How to model Stability across: – DS storage, multiple temperatures/times – DP storage, multiple temperatures/times • We run studies at each temperature, in parallel (to save the time) • However, final commercial product goes through each temperature in serial fashion (and may not hit max time) Outline • Biologics, but concepts apply to small molecules • • • • • • Proteins • Vaccines Stability of Biologics DS and DP Stability data (ICH, other) Modeling, assumptions, data in, output Usage scenarios Questions, future work Stability of Biologics – Storage: • In process holds: ambient, refrigerated • Bulk Drug Substance – In-process – Frozen • Cryo-Vessels • Glass vials (lyophilized powder typically, some PFS) – Temperatures: • • • • 25C, 40C – accelerated conditions -40C “typical” DS frozen storage. DP (liquid or lye powder) typically 2-8C (5C here) -70C and -20C also used at times Storage cost$ • -40°C walk in that can hold up to 40 x 300L cryovessels: ~ $1.33 million • CU5000 + Freeze/Thaw 100 : $700,000+ • CU5000 + cryomixer: almost $500,000 • Modular freezer that can hold 9 x 300L cryovessels is over $500,000 • Cost: Controls, engineering, scale, freeze profiles Control Unit and Cryovessel Freeze / Thaw unit Exposure / Stability data • Data collected at different steps – – – – – – In Process Holds (DS/API) Storage/Packaging/Labeling Formal ICH Stability lots Excipient Robustness Studies Shipping studies Long Term Storage (DP) Patient Exposure vs Data • At patient usage, the product has been exposed to multiple temperatures for varying amounts of time • Modeling should reflect this • Could go to conditional modeling if data were available (out of scope) • Stability testing in parallel Total Degradation • What is the net impact? Net uncertainty? • Which attributes are the most limiting? • Which storage temperature / time combination is the most limiting? • What times periods could/should be changed? • Tradeoff of storage cost and degradation • Statistics can play a strategic role here Design • Patients: – samples exposed to maximum storage at each intended temperature Analytical – Remaining samples “next” storage for maximum time Analytical (ie serial study) – Would only need data from ‘last’ condition • Internal Studies: – Ideal study would take too long – Data collected in “parallel” – Need data from all conditions Stability Data • • • • • • ICH Batches: 0,1,3,6,9,12,18,24 (typical) Ad hoc studies Excipient Robustness studies In process studies Shipping studies Assays of interest – Size Exclusion – Monomer / Purity – etc Degradation Rates from Stability Studies of different lengths, at different Temperatures Three rates for Drug Substance 0 9 Two rates for Drug Product 18 27 36 Cumulative Degradation over Maximum Storage Time Spec Limit = problem? (what about allowance for uncertainty?) DP 2 Each study estimates the Degradation rate for that condition. Net degradation within a condition = Rate * Time DS3 DS 2 DS 1 DP 1 To predict the mean we can use the slopes and intercepts from each study Stability studies may be of different lengths than the storage conditions 12 24 36 48 Combining across Temperatures • Follow ICH guidance? – at every storage – use worst case – which batches / lots /studies to combine • Reasonable model at each storage? – Not an ICH stability analysis – Slope may not be stable initially • Common Slope / Intercept at each storage? – Follows the center of the process – Gives an idea if storage times might work • Assumptions Modeling – Slopes within storage condition independent of starting values – Linear fit regardless of length of storage • “Daisy Chain” the predictions together – data at end of “this” storage lines up with data at the start of “next” storage – This is what **would** happen if the study were conducted serially – rate of change estimated within each temperature condition Flow • Data in: – Stability Exposure Data (actual, multi temperature) – Production Exposure Data – many scenarios possible (what if scenarios?) – Multiple Assay(s)? • Output (per assay) – Predictions within each storage – Predictions ACROSS multiple storage Scenarios – – – – – What is limiting assay? What storage “burns” the spec window? Should a storage time be shortened? Could a storage time be lengthened? Would a different assay be limiting under a different scenario? – What is the cost to go to colder storage relative to degradation slope: – 5C (slope, cost) vs -20C (slope, cost) – Limiting assay may change Stacking across storage – Time scale is easy – New Time = sum (all times so far) – May not be the same for actual vs. production – Response is a little trickier: – Initial storage: need Intercept (Tzero) and slope – Subsequent: need only the slope, ie rate – New Response = Tzero + Sum(duration x slope) – Depends on actual or production – Actual – the analytical going into the model – Production – the storage times you want to consider Statistical Details • • • • Prediction at “exposure” is sum of predictions: Each piece has an associated variance df error add across the regression models RMSE could be a pooled RMSE – – – – more efficient estimation assumes variance does not depend on the mean model selection would be more complicated rationale: “same” assay, “same” compound all storage ( increase in Yhat during max time ) Conf Limits Statistical Details Similar calculations for each group (SAS loop through groups) var Varp Pred se sep t = = = = = = rmse1**2 * ( 1/n1 + (x - xbar1)**2/ss_x1); rmse1**2 * (1 + 1/n1 + (x - xbar1)**2/ss_x1); int1 + slope1 * x; sqrt(var); sqrt(varp); tinv(1-&alphalevel/2,df1); accumulate across storage, eventually leading to: upperCLM = pred + t * se; lowerCLM = pred - t * se; upperCLP = pred + t * sep; lowerCLP = pred - t * sep; Variances add but t-mult drop with increasing degrees of freedom, so width grows at less than sqrt(# groups) Comment • I do NOT see this as a spline or change point regression • To do this, we would need to conduct the serial study • All samples exposed to ONE and only one condition – – – – Initial sample: Tzero or baseline, ie intercept First storage: Tzero + degradation in that condition Second: Tzero + degradation in that condition Etc • Total degradation to the product: – Tzero + Degradation in Storage 1 + Degradation Storage 2 + Caveats • Worst batch may change over time • All Stability data used even if production is less »RMSE from full stability design »Prediction variance based on full design, ie all time points • Model fit should be checked • Nonlinearity may occur • One batch / one result may be very influential Input Time Storage Assay Spec DS/DP ?? 0 -40C Purity . . . 1 . . . . . 3 . . . . . 6 . . . . . 0 25C Acidic . . . 0 25C Basic . . . Output Output for CS/CI Common Slope Common Intercept Separate Slopes, Separate Intercepts (worst case) Recap / Questions • Modeling reflects exposure seen in consumer product • Uses any data available • Can consider different scenarios – ICH, CS/CI, alpha levels – Varying time within each temperature • Internal decision making tool