PPT - Auburn University

advertisement

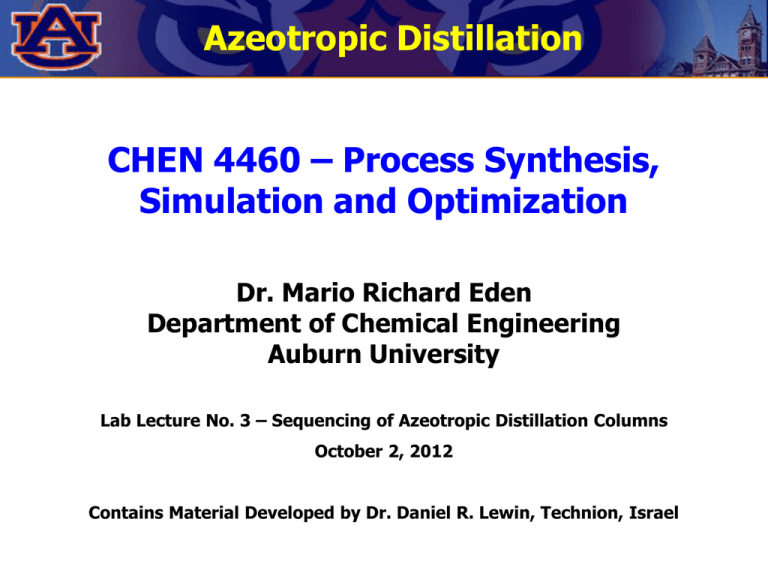

Azeotropic Distillation CHEN 4460 – Process Synthesis, Simulation and Optimization Dr. Mario Richard Eden Department of Chemical Engineering Auburn University Lab Lecture No. 3 – Sequencing of Azeotropic Distillation Columns October 2, 2012 Contains Material Developed by Dr. Daniel R. Lewin, Technion, Israel Introduction • When two or more components differ in boiling by less than approximately 50C and form a nonideal liquid solution, the relative volatility may be below 1.10. • Then ordinary distillation may be uneconomic, and if an azeotrope forms even impossible. • In that event, the following separation techniques, referred as enhanced distillation by Stichlmair, Fair, and Bravo, should be explored: – – – – – – Extractive distillation Salt distillation Pressure-swing distillation Homogeneous azeotropic distillation Heterogeneous azeotropic distillation Reactive distillation Example 1 • Given that methyl acetate (1), which boils at 57.8C, methanol (2), which boils at 64.7C and n-hexane (3), which boils at 68.7C. A. Sketch any boundaries across which the residue curves cannot traverse. B. Sketch the residue curves for three feed compositions: Mole Fractions Component I II III 1 0.70 0.15 0.15 2 0.15 0.70 0.15 3 0.15 0.15 0.7 Example 1 • Note the existence of compositions are in mol %: four azeotropes, Azeotrope where T oC Methyl acetate (65%), methanol (35%) Binary 53.5 Methanol (51%), n-hexane (49%) Binary 50.0 Methyl acetate (60%), n-hexane (40%) Binary 51.8 Methyl acetate (31%), n-hexane (40%), methanol (29%) Ternary 49.0 Example 1 – Solution Plot pure components on vertices with Tb Plot all azeotropes diagram with Tb (2) 64.7 B oC on 0 (3) He xa ne 0.8 tha Me << 0.2 << 0.4 0.6 ) l (2 no Plot the residue curves connecting all azeotropes, azeotropes & vertices, and finally vertices & vertices with arrow heads pointing towards increasing boiling point temperatures 1 50oC 0.6 0.4 o 49 C 0.8 0.2 1 (3) 68.7 C oC 0 53.5oC 0 0.2 0.4 MA (1) >> o 0.6 51.8 C 0.8 A oC 1(1) 57.8 Example 1 – Solution Plot pure components on vertices with Tb Plot all azeotropes diagram with Tb (2) 64.7oC on 0 (3) He xa ne 0.8 tha Me << 0.2 << 0.4 0.6 ) l (2 no Plot the residue curves connecting all azeotropes, azeotropes & vertices, and finally vertices & vertices with arrow heads pointing towards increasing boiling point temperatures 1 50oC 0.6 Plot additional residue curves that “arch” towards intermediate temperatures on the way to the end point 0.4 o 49 C 53.5oC 0.8 0.2 1 (3) 68.7oC 0 0 0.2 0.4 MA (1) >> o 0.6 51.8 C 0.8 Feed I o 1(1) 57.8 C Example 1 – Solution Plot pure components on vertices with Tb Plot all azeotropes diagram with Tb (2) 64.7oC on 0 (3) He xa ne 0.8 tha Me << 0.2 << 0.4 0.6 ) l (2 no Plot the residue curves connecting all azeotropes, azeotropes & vertices, and finally vertices & vertices with arrow heads pointing towards increasing boiling point temperatures 1 50oC 0.6 Plot additional residue curves that “arch” towards intermediate temperatures on the way to the end point 0.4 o 49 C 53.5oC 0.8 0.2 1 (3) 68.7oC 0 0 0.2 Feed III 0.4 MA (1) >> o 0.6 51.8 C 0.8 Feed I o 1(1) 57.8 C Example 1 – Solution Plot pure components on vertices with Tb Plot all azeotropes diagram with Tb (2) 64.7oC on 0 (3) He xa ne 0.8 tha Me << 0.2 Feed II << 0.4 0.6 ) l (2 no Plot the residue curves connecting all azeotropes, azeotropes & vertices, and finally vertices & vertices with arrow heads pointing towards increasing boiling point temperatures 1 50oC 0.6 Plot additional residue curves that “arch” towards intermediate temperatures on the way to the end point 0.4 o 49 C 53.5oC 0.8 0.2 1 (3) 68.7oC 0 0 0.2 Feed III 0.4 MA (1) >> o 0.6 51.8 C 0.8 Feed I o 1(1) 57.8 C Example 1 – Solution Plot pure components on vertices with Tb Plot all azeotropes diagram with Tb on Plot the residue curves connecting all azeotropes, azeotropes & vertices, and finally vertices & vertices with arrow heads pointing towards increasing boiling point temperatures Plot additional residue curves that “arch” towards intermediate temperatures on the way to the end point Example 2 • A stream consisting of a mixture of A, an organic component, and water, B, which forms an azeotrope. A separation process is to be designed to obtain pure products A and B. The plant manager suggests that you investigate the possibility of using component C as MSA. F A 40% B 60% Component Boiling Temperature (K) A 360 B 400 C 370 Azeotrope I Azeotrope II Azeotrope III Azeotrope IV 50% 55% C 50% 45% Temp 350 K 360 K 55% 30% 45% 45% 25% 330 K 315 K Example 2 • Indicate the location of the azeotropes on a ternary diagram, as well as representative residue curves. • Suggest a process for the separation of A and B into pure products and show its operating lines on the ternary diagram. • Draw a PFD for your process. Indicate flow rates of all internal and external streams as multiples of the flow rate of F. Example 2 – Solution 360 K III, 330 K I, 350 K IV, 315 K 400 K II, 360 K C 370 K Example 2 – Solution S2 360 K F B2 M1 D2 D1 M2 B1 III, 330 K F M1 S1 D1 B2 I, 350 K M2 D2 S1 S2 IV, 315 K B1 400 K II, 360 K C 370 K