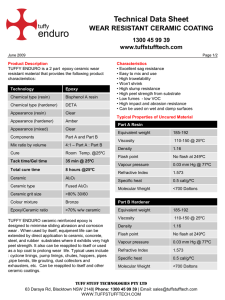

Features - Benefits

advertisement

Cost Effective Reliability Solutions Ceramic and Metallic Entrained Epoxy Coatings Representative Name: Company History • 1994: Created by Glassflake International, Rezorect was invented as a product line of Epoxy based ceramic and metallic entrained putties used as a Reliability Solution. • 2007: Glassflake International merger with Corrocoat. • 2011-2012: Corrocoat tested the properties of the Rezorect products formulations so as to improve upon those properties. • 2013: Rezorect Manufacturer’s Representatives program is born to provide direct service to customers all over the North America. The Reliability Dilemma - With Respect to Corrosion / Abrasion “Get the maximum life out of each asset!”...but: • Don’t spend too much money, • Use your own people, • By the way, Production rates are increasing; and… • Don’t be wrong! The Reliability Dilemma - With Respect to Corrosion / Abrasion Vertical Pump Impeller – 8” diameter New Impeller: $3,000 Uncoated: +/- 1 year (Replace) Rezorect: $1,000 Coated: +/- 2 Years (Repair) Comparative ROI: 600% What is Value? Why do we so often make the easy decision to replace? Value Offering Inspection & Support Supply Engineering Specification Manufacture Operating Environment Evaluation System • Operating Environment defines the Corrosion Rate; Chemistry, Heat, Substrate, etc. • The Properties of the barrier coating must resist the operating environment; temp., chemical, abrasion resistance, flexibility, etc. • The Components of the coating system chosen define the properties therein; resin, fillers, etc. • Choose the best solution that has the components that resist the operating environment…but still meets your value hierarchy. REPAIRS DYNAMIC PROTECTS STRENGTH MACHINEABLE SOLUTION Rezorect 122: Brushable Ceramic Features - Benefits • High gloss, smooth finish reduces friction thereby increasing pump efficiency by as much as 10%. • Can be applied on it’s own or as a topcoat to Ceramic Wearing Compound • Easily mixed and applied • 100% solids = 0 VOC’s Fluid Efficiency = Energy Savings Fluid Efficiency Performance Parameter Flow (L/S) Head (m) Pump Input (kW) Best Efficiency Original Specification Performance prior to refurbishment Performance after refurbishment with Brushable Ceramic 1,041.67 1,030.36 1,030.36 66.10 63.40 63.40 810 800 740 98 83.34% 71.00% 86.43% Performance Data on 24 inch split case pump, annual savings $42,000 / year. Rezorect 125: Ceramic Wearing Compound Features - Benefits • Trowel Applied, highly abrasion resistant • Specifically sized ceramic particles and silicon carbide • Used to line slurry / raw feed WW pump volutes, particle transfer chutes, mix tanks, centrifuge housings and ideal for rubber repair Rezorect 134: Mighty Metal Features - Benefits • Specifically designed for repairing metal parts subjected to high shock loads or extreme pressures • Machinable • Non-sag, non-shrink properties allow > ¼” hold up on vertical surfaces • Ideal for repairing shafts Rezorect 154: Steel Putty Features - Benefits • Designed to repair and rebuild steel parts and equipment • Easy to use, minimizing down time • Machinable • Cost effective Rezorect 142: Quickset Steel Putty Features - Benefits • Sets up in 5 minutes • Ideal for repairs that need to be implemented quickly for immediate return to production • Machinable • Cost effective Paper plant Application vaccum pump coating Wear and cavity Rejected vacuum pump After Abrasive Blasting After Application PRODUCT USEd FOR THIS APPLICATION: REZORECT STEEL PUTTY, MIGHTY METAL AND BRUSHABLE CERAMIC Paper plant – Water Pump Application Material used Cosmospoxy Steel Bond, Cosmospoxy Brushable ceramic Slurry Pipe Wear surface After Application Transformer Leakage Arresting Oil leakage Oil leakage Repair with Rezorect 154 – Quick Set Steel Putty Leakage arrested Insulation repair & coating Broken part of insulator After Repair REPAIR AREA More Rezorect Products • • • • Stainless Steel Putty Aluminum Putty Submarine Putty High Temp, Chemical Resistant Putty • Concrete Patch / Iso Polymer Concrete • Epoxy Adhesives Corrocoat Glassflake Reinforced Polymer Solutions • Polyester Glassflake Coatings – +30 Year Life • Vinyl Ester Glassflake Linings – Resistant to 1200+ Chemicals, pH 114 • Surface Tolerant Epoxy Coatings • Acid / Caustic Resistant Concrete Coatings Aluminum Chloride Baghouse • AlCl was reacting with dew and rainwater to form Hydrochloric Acid, which corroded the steel in 5 days. • Corrocoat USA selected Polyglass VE to coat the externals and added Polyglass VE Veilcoat to provide a friction reducing surface on the internals. Coal Fired Power Plant – Demineralization Sump Lining • Internal lining and concrete repair of 50’ x 15’ x 29’ deep Neutralization Sump • Lining required to be resistant to 90% H2SO4 and NaOH Kaolin-Sand Slurry Grinder Tank and Blades Acid / Caustic Secondary Containment and Trench Lining Any Questions? CONTACT US • • • If you have any questions or would like further information, please contact us using the details below. Corrocoat / Rezorect c/o Glassflake International, Inc. 6525 Greenland Road Jacksonville, FL 32258 T. +1 (904) 268.4000 F. +1 (904) 268.3197 E. info@rezorect.com MR Contact Information: