Diapositiva 1

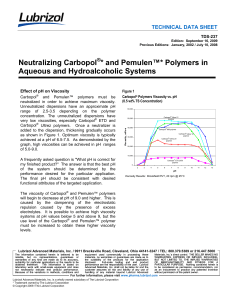

advertisement

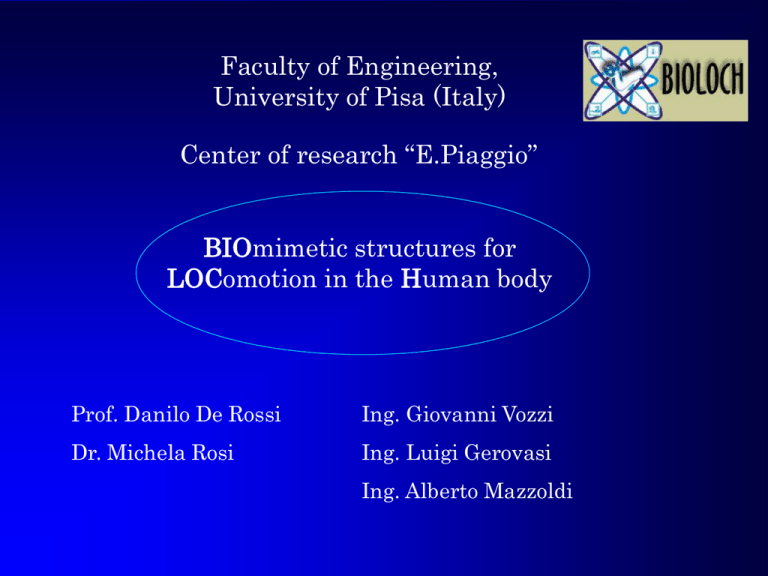

Faculty of Engineering, University of Pisa (Italy) Center of research “E.Piaggio” BIOmimetic structures for LOComotion in the Human body Prof. Danilo De Rossi Ing. Giovanni Vozzi Dr. Michela Rosi Ing. Luigi Gerovasi Ing. Alberto Mazzoldi Objective: The aim of the project is to understand motion and perception system of lower animal forms, such worms, insects and snakes and eels, and to design and fabricate bio-inspired mini- and micro-machines able to navigate in difficult cavities, in particular in the human intestine. To project a micro robot To obtain this goal To test mucoadhesive and Shape memory Polymers Our attention is focused on earthworms, geckos and snails To microfabricate short “legs” from shape memory polymers To cover the SMP legs with mucoadhesive polymers Shape Memory Polymers and Shape Memory Alloy They both regain the memorized shape (original shape) when heat is applied but there is difference in that "alloy" is hardened when heat is applied while "polymer" is hard (like plastic) at low temperature but it is softened (like rubber) when heat is applied. "Polymer" can be changed in shape into any direction to a desired degree, chemicalresistance, standing ability against repeated deformations and ability to fit users' needs. Fig 1. Shape-memory polymer converts from a temporary shape (left) to its parent shape (right) in 45 seconds at 65 ºC. A shape-memory polymer is a product, created by utilization of the shape memorizing mechanism of elastomer of polyurethan family, developed by Mitsubishi Heavy Industry. The Shape Memory Polymers combine the advantages of polyurethane with the characteristics of “smart material” technology. SMP changes mechanical properties from hard to soft quickly when the temperature changes SMP changes shape when heated and retains its new shape when quickly cooled Properties: SMP undergoes transformation at biocompatible temperatures in the range of normal body temperature SMP is available in pellets or solution, and can be easily compounded, formed by extrusion, injection molding, coating or casting process in conventional manufacturing environments When ambient temperature is below the activation point The molecular structure is rigid When ambient temperature is above the activation point Micro-Brownian movement creates gaps between molecules Characteristic of mucus Mucus forms a continuous, insoluble adherent gel layer which protects the underlying mucosa from the hostile environment of the intestinal lumen. The mucus consists of about 95-99% water and 5-1% glycoproteins, plus a large number of other components such as electrolytes, lipids, proteins and nucleic acids The turnover time of the mucus gel layer appeared to be no longer than approximately 1-4h, although this number is based on several assumptions and was obtained from isolated rather than normal gut segments. The mucin protein core consists of highly glycosylated regions (resistant to proteolysis) regions sparsely or non-glycosylated (susceptible to proteolysis) The polymeric structure is stabilized by interchain disulphide bridges. There are approx. 150 disulphide bridges and 53 free thiol groups per mucin polymer. The proteins are particularly rich in proline and in hydrophobic amino acids. Mechanism and theory of mucoadhesion Many theories have been put forward to explain the mechanisms of mucoadhesion, including electric theory, adsorption theory, diffusion theory and wetting theory, although no theory alone can elucidate this process. Intimate contact of mucus and polymer Penetration into the mucus gel Chemical binding The electrostatic attraction is suggested to be able to facilitate the intimate contact, while the presence of hydrophilic groups such as OH, NH2 and COOH, sufficient polymer chain flexibility and favourable polymer conformation are considered to be essential for successful mucoadhesion. Electronic theory Adsorption theory Wetting theory Diffusion theory Electronic theory: Bioadhesion in this case is due to an attraction across the electrical double layer. Adsorption theory suggests that bioadhesion is due to secondary forces such hydrogen bonding. Wetting theory uses interfacial tension to predict the degree of spreading of a gel on the mucosa, which can than be used to predict the degree of mucoadhesion Diffusion theory: interpenetration of polymer chains are responsible for mucoadhesion. It is believed that an interpenetration layer of 0,20,5 μm is required to produce an effective bond. Materials and methods Mucin type I (BSMG,) with 12% of sialic acid; Mucins type II, with 1% of sialic acid; Mucins type III (PSI) with 1% of sialic acid; Many studies use three types of mucins, because different amount of sialic acid can induce different characteristics of mucoadhesion Polymers:Carbopol 974P, Carbopol 971P e Noveon AA-1 The mucin is prepared at 4%w/w, and the polymer at 0,25-1,5% w/w by dispersing the required amount of polymer and mucin in ultra pure water. The pH is adjusted to physiological pH (7.4) using 1 M NaOH or TEA and the samples are then allowed to equilibrate at 4°C overnight. Same polymers that present mucoadhesive properties are: Hydroxy propyl cellulose HPC Poly vinyl pyrrolidone PVP Hydroxy propyl methyl cellulose HPMC Sodium carboxymethyl cellulose CMC Poly vinyl alcohol PVA Poly acrylic acid e Poly methacrylic acid PAA e PMA Hyaluronic acid Chitosan Poly acrylic acid e PEG Gelrite® Carrageenan type I e II Carbopol 971P® CP, 974P e Noveon AA-1 Carbopol polymers properties: Carbopol polymers are high molecular weight, crosslinked, acrylic acid-based polymers. Carbopol homopolymers are polymers of acrylic acid crosslinked with allyl sucrose or allylpentaerythritol. Carbopol copolymers are polymers of acrylic acid, modified by long chain (C10-C30) alkyl acrylates, and crosslinked with allylpentaerythritol. Noveon's pharmaceutical resins are offered as fluffy, white, dry powders. Hydrogen bonding is a key part of the mechanism of the mucoadhesion Carbopol contain a great number of carboxylic acid –COOH groups pH value low, acidic conditions The polymer adheres better at acidic pH levels , acid groups are ionized less than 10%, so they form H-bonds pH value high, basic conditions The polymer is ionized, under more alkaline conditions, the Carbopol gels are very highly swollen, and the chains are stiffened by electrostatic repulsion of the anionic charges along the backbone. Our idea is to build a micro robot, able to move autonomously, and to unite this with legs of a Shape Memory Polymers covered with mucoadhesive polymers. Test the temperature dependent properties of SMP Build micro legs of SMP with modulable mechanical resistance, by varying the temperature, the shape of polymer Test the mucoadhesive properties of Carbopol polymer by test this polymer by specific method Vary the pH value and the concentration of polymers, to test the mucoadhesive properties Testing device: functioning scheme Sample trolley Oscillatory plane Brushless Motor reduction Testing device: detail of trolley green deformable sheet blue strain gauge To project a micro-robot Two counter motors An eccentric mass Asymmetrical skates Total weight 70g Length 70mm Second prototype: dimensions 31/25 mm x 61 mm Eccentric rotors CCD and LED bulb Lithium batteries