METALLURGY

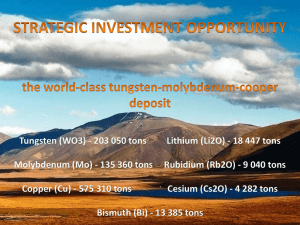

advertisement

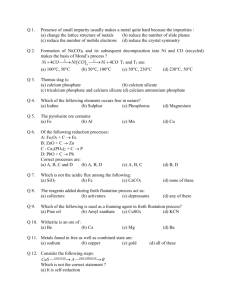

METALLURGY Metallurgy • The extraction of metals from their ores and refining it is known as metallurgy Metal urgy Enrichment of the ore removal of gangue Conversion of the ore into suitable form Physical method Chemical method Hydraulic washing Leaching froth floation electromagnetic seperation Roasting Calcination Reduction Refining By heating(Hg) Liquation(Sn,Pb) By heating with C( Zn ,Fe) Distil ation (Zn, Hg ) Electrolytic reduction (Na,Mg . . .) Electrolytic refining ( Cu, Hg ,AU) ENRICHMENT OF ORE • Process used for removal of the “GANGUE” • GANGUE – Soil, Sand and Earthy Impurities Enrichment processes • Hydraulic washing Froth Floatation Electromagnetic separation Chemical Method • • • • • • • Dissolve ore + Hot and Conc. NaOH Al2O3 + 2NaOH -> 2NaAlO2+H2O Filter it- add dil HCl NaAlO2 + 2H2 O + HCl - Al(OH)3 + NaCl Filter the ppt wash,dry and Ignite 2Al(OH)3 - Al2O3 + 3H2O Pure Bauxite is obtained REDUCTION • Conversion of concentrated ore into a more • • • • suitable form Roasting -- Heating the Sulphide ore in presence of air to form an Oxide ore 2ZnS+3O2 2ZnO + 2SO2 Calcination -- Heating the Carbonate ore in the absence of air to form an Oxide ore ZnCO3- ZnO + CO2 Reduction • • • • • • • Low in the reactivity series ---- Heating ---- e.g..2HgS + 3O2 2HgO +2SO2 2HgO(S) - 2Hg + O2 (g) Middle in the reactivity series Heating with C (Smelting) ZnO + C --Zn + CO High up in the reactivity series Electrolytic reduction REFINING • LIQUATION: Used for metals having low M.P. Pb,Sn Impurity(High M.p.) Metal (low M.P.) Hearth REFINING • • • • DISTILLATION Metals used are Volatile - Hg ,Zn The impure metal is heated in a retort. The Pure metal distils over and is condensed in a receiver. • The impurities are left behind in the retort k • ELECTROLYTIC REFINING • Metals used are ---Cu,Zn,Sn,Ni,Ag,Au… CuSO4 + H2SO4