L05C - Clarkson University

advertisement

L05C: Surface defects

• Defects arise in all stages of production and processing.

CASTING

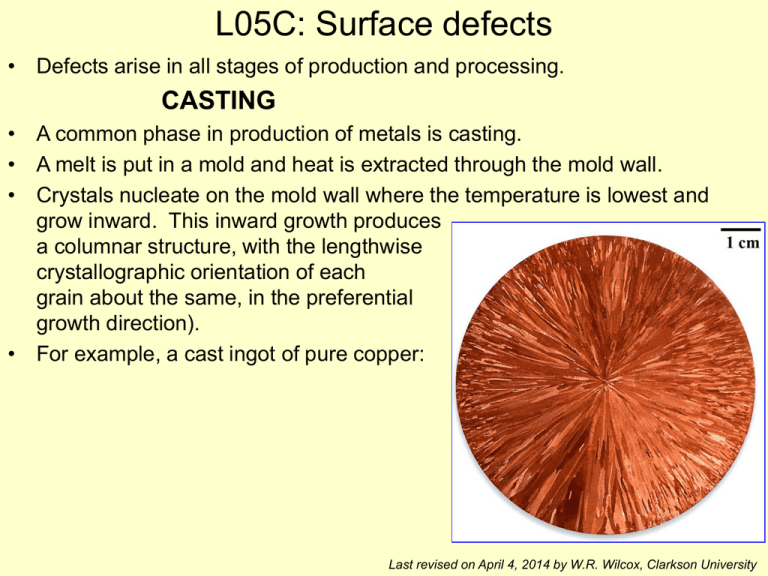

• A common phase in production of metals is casting.

• A melt is put in a mold and heat is extracted through the mold wall.

• Crystals nucleate on the mold wall where the temperature is lowest and

grow inward. This inward growth produces

a columnar structure, with the lengthwise

crystallographic orientation of each

grain about the same, in the preferential

growth direction).

• For example, a cast ingot of pure copper:

Last revised on April 4, 2014 by W.R. Wilcox, Clarkson University

Simulation of casting of an Al-Si alloy with

nucleation of new grains in the melt.

(http://www.tms.org/pubs/journals/jom/0201/thevoz/thevoz-0201.html )

View in projection mode to see the action.

Microstructure depends on many things:

• the alloy composition

• how close the melt is to the freezing point

when poured it

• how rapidly it's cooled

• whether the cooling's all around or mostly

on the bottom

•etc.

Grain Refiner - added to make smaller,

more uniform, equiaxed grains.

Casting of alloys

• Alloy crystals tend to grow as dendrites:

https://www.youtube.com/watch?v=S07fPo45BvM

• If the melt falls below its melting point while being added to the mold, small

crystals may have already nucleated in the melt and be floating around.

• Dendrite arms may detach and float around in the melt.

• After solidification is complete, grains formed by the floating crystals have

random shapes and orientation.

The region occupied by these in

the casting is called “equiaxed.”

• Example: Ti–47.2 Al–1.50:

http://www.sciencedirect.com/science/article/pii/S0966979507000817

Polycrystalline Materials

Grain Boundaries

• regions between crystals

• transition from lattice of one side

to that of the other

• High-angle grain boundaries

– highly disordered

– low density

– high impurity diffusivity

– high chemical reactivity

• Low-angle grain boundaries

– slightly disordered

– made up of a line of

dislocations, which can be

seen by usual methods of

revealing dislocations.

4

Low-angle grain boundaries

• If formed only by edge dislocations it’s a “tilt

boundary”

• If formed only by screw dislocations it’s a twist

boundary. Most are mixed.

• Dividing line between high-angle and lowangle boundaries is fuzzy, roughly between

10o and 20o

• If individual dislocations can be seen, can be

considered low angle.

• For example, etch pits on NaCl & YAlO3

Stacking faults

• Found in closed-packed face-centered cubic and hexagonal crystals

because only the second-nearest neighbors are different at the fault

• Reminder: Close-packed planes in FCC

are in order ABCABC {111}, while in HCP

the order is ABAB {0001}.

• Example: Austenitic steel:

• FCC–hexagonal stacking faults also

common with the diamond structure and

the zinc-blende structure. (Diamond &

Lonsdalite, zinc-blende & wurtzite.)

http://amadm.unileoben.ac.at/SFE_Steel.html

http://iopscience.iop.org/0953-8984/25/13/135002/article

Twin boundaries

http://en.wikipedia.org/wiki/Crystal_twinning

• Twins are two grains whose lattices are at a definite, reproducible,

orientation with respect to one another.

• Crystal lattices in the twins may be mirror images of one another, i.e.

reflection twins.

Si, for example: http://www.tf.uni-kiel.de/matwis/amat/def_en/kap_7/backbone/r7_1_1.html

• When the two lattices share all atoms at the boundary they are called

“coherent.” Common, but not always.

• Twinning can occur during plastic deformation, transformation to a different

crystal structure, or crystal growth.

• The mechanisms for twinning during deformation and transformation are

generally well understood.

• The mechanisms for twinning during crystal growth are generally unknown.

• Twin boundaries are often planar, and appear as straight lines in a section.

• But sometimes twin boundaries jog so that they appear curved at low

magnification.

• Twin boundaries are often parallel to one another.

Copper, for example: http://www.nature.com/am/journal/2009/200904/full/am2009128a.html

Examples of stacking faults & twins in metals

• The spheres labeled “A” in the figure to the

right from VMSE represent metal atoms in

a close-packed plane. Positions B and C

show the two possible locations for the

next close-packed plane on top of this one.

•

•

•

•

•

Planes stacked in the order ABCABC… generate a FCC crystal.

In FCC, one type of stacking fault can be represented by ABCBCABC.

In FCC, a reflection twin can be represented by ABCBCABC.

Planes stacked in the order ABABAB… generate a HCP crystal.

In HCP one type of basal plane (0001) stacking fault can be represented by

ABACABA

• Many twin planes observed in HCP and much more difficult to illustrate.

• More complex twins in BCC.

Interface between two phases

• Another type of surface defect. For example:

– Second phase inside the solid

– Thin films (extremely important technologically)

– Small solid particles in a gas or liquid.

• Notice that the interface may have a structure quite different from those of

the adjacent bulk phases (http://en.wikipedia.org/wiki/Surface_reconstruction)

• If we assume the crystal structure exists up to the surface, several types of

defects can exist at this surface:

Some chemical reactions may take

place only at specific surface sites.

Step

Solid Catalysts and Surface Defects

• A catalyst increases the

rate of a chemical reaction

without being consumed

• Active sites on catalysts

are normally surface

defects

Fig. 5.15, Callister & Rethwisch 4e.

Single crystals of

(Ce0.5Zr0.5)O2

used in an

automotive catalytic

converter

Fig. 5.16, Callister & Rethwisch 4e.

Volume defects

• Second phase in solid. Can be void, gas bubble, or another solid.

• When insoluble foreign particles are present in a melt, these may be trapped

in the solid during solidification.

• If the impurity is soluble in the solid at the melting point, it may precipitate

out as the solid is cooled. (Solid solubility normally decreases as

temperature is decreased.) These precipitates may be gas bubbles,

impurity itself, or compound between impurity and solid.

• Example: carbon flakes in

gray cast iron:

• Other methods of forming

composite materials:

• Mixing of concrete and then

hardening by formation of

hydrate crytals.

• Mixing of fibers with a

monomer and then

polymerizing.

http://www.metallographic.com/Technical/Metallography-Intro.html

Defects in Polymers

• Defects due in part to chain packing errors and impurities such

as chain ends and side chains

Adapted from Fig. 5.7,

Callister & Rethwisch 4e.

12